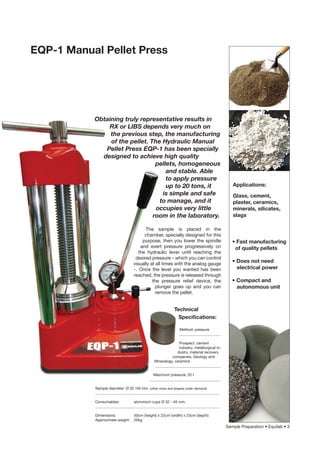

The document describes various analytical instruments for sample preparation, including the eqp-1 manual pellet press, f series induction fluxers, eqp-100 & eqp-200 pellet presses, eqm-400 ball mixer mill, and eqr-100 vibratory disc mill. Each instrument is designed to optimize the sample preparation process for different applications, ensuring high quality, homogeneity, and stability in the resulting samples. The document provides technical specifications, applications, and features such as programmable controls, ergonomic designs, and efficient processing capabilities.