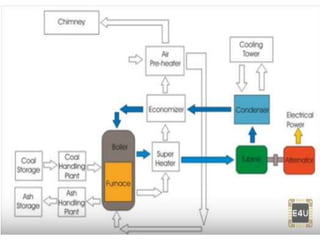

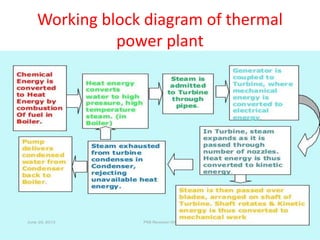

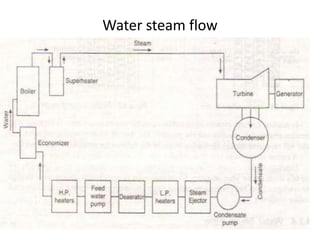

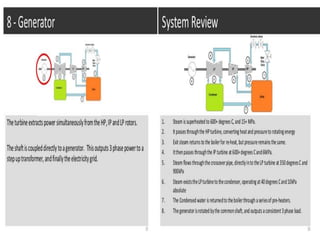

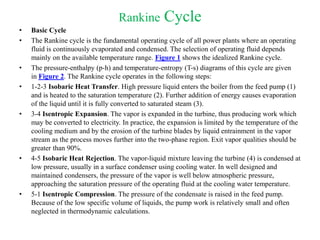

The document describes the key components of a steam power plant, including:

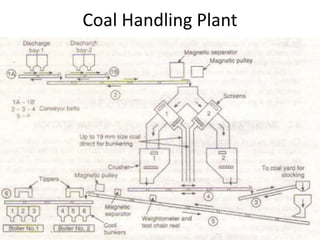

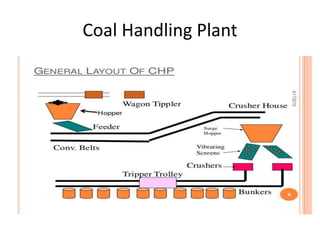

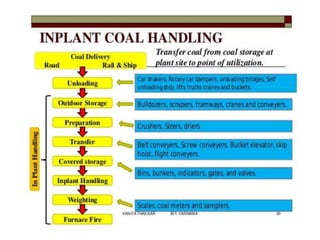

1. The coal handling plant which includes unloading, conveying, and crushing coal.

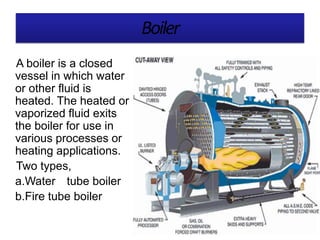

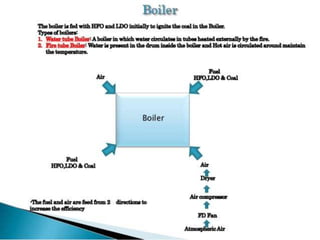

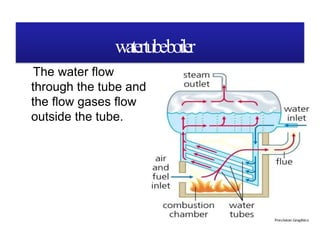

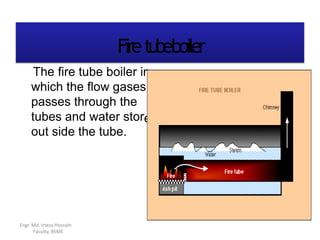

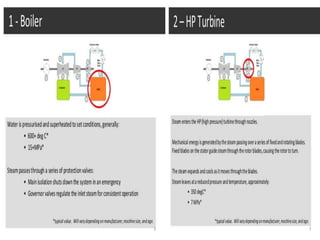

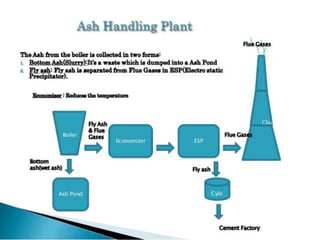

2. The boiler, which uses water tubes or fire tubes to generate high pressure steam.

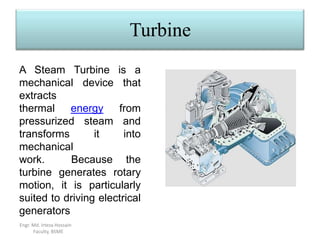

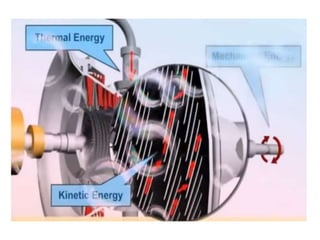

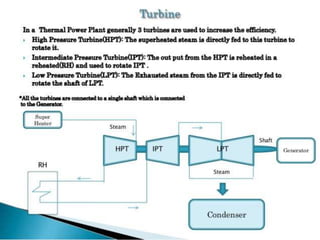

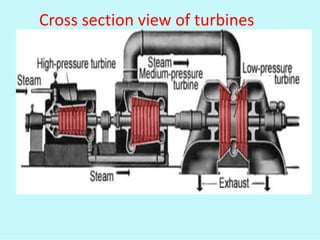

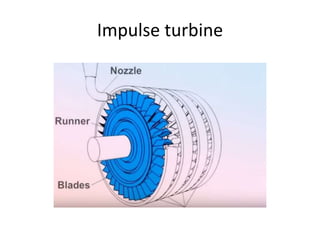

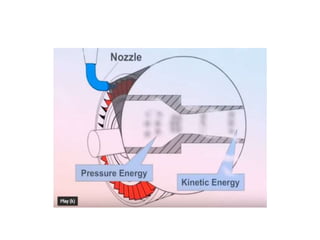

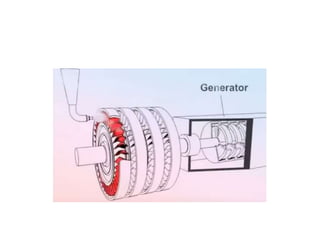

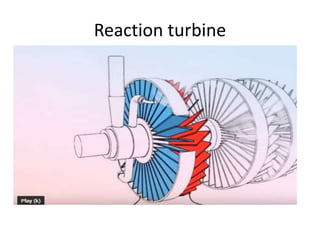

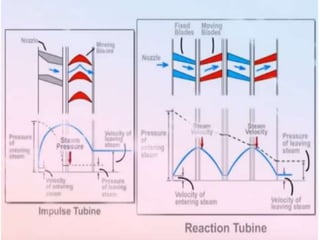

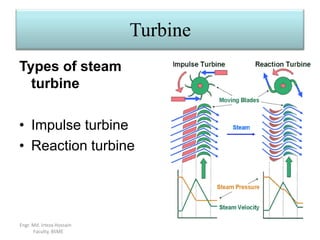

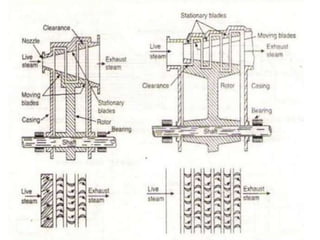

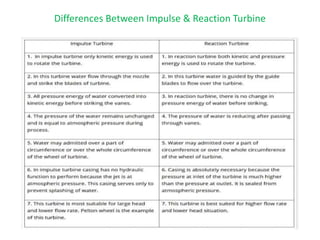

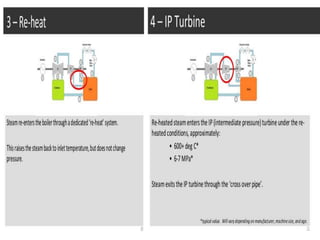

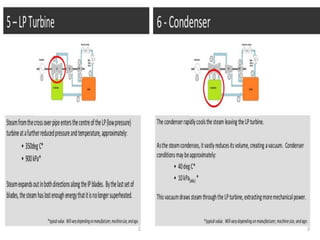

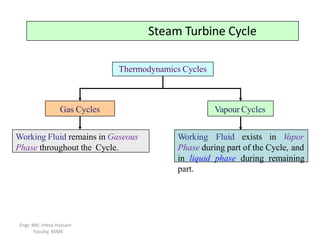

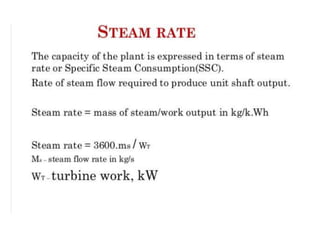

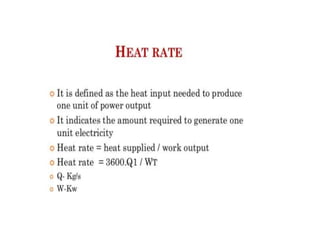

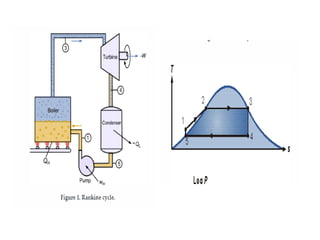

3. Turbines which convert the thermal energy of steam into rotational motion using impulse or reaction blades.

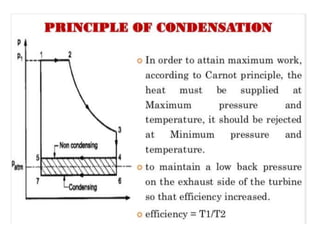

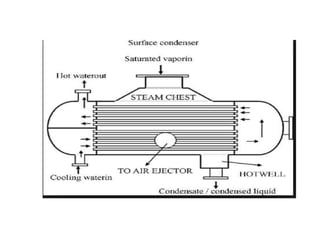

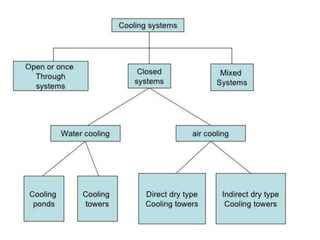

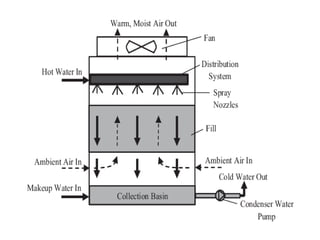

4. Condensers which cool the steam from the turbines before it returns to the boiler via feed pumps to repeat the Rankine cycle that powers the plant.