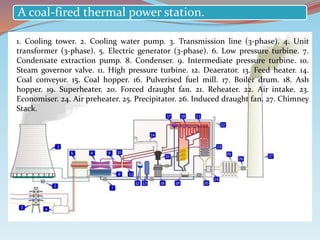

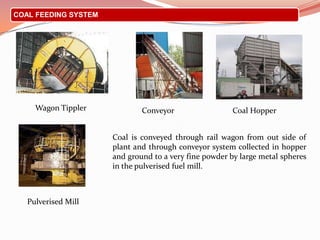

This document describes the key components and processes involved in a thermal power plant. Water is heated to produce steam, which spins turbines connected to generators to produce electricity. The main components are the boiler, turbines, condenser, cooling tower and auxiliary systems. Coal is pulverized and burned in the boiler to heat water and produce high pressure steam. The steam powers high, intermediate and low pressure turbines in succession to generate electricity before being condensed back into water in the condenser. The water is cooled in the cooling tower and recycled to the boiler to repeat the process.