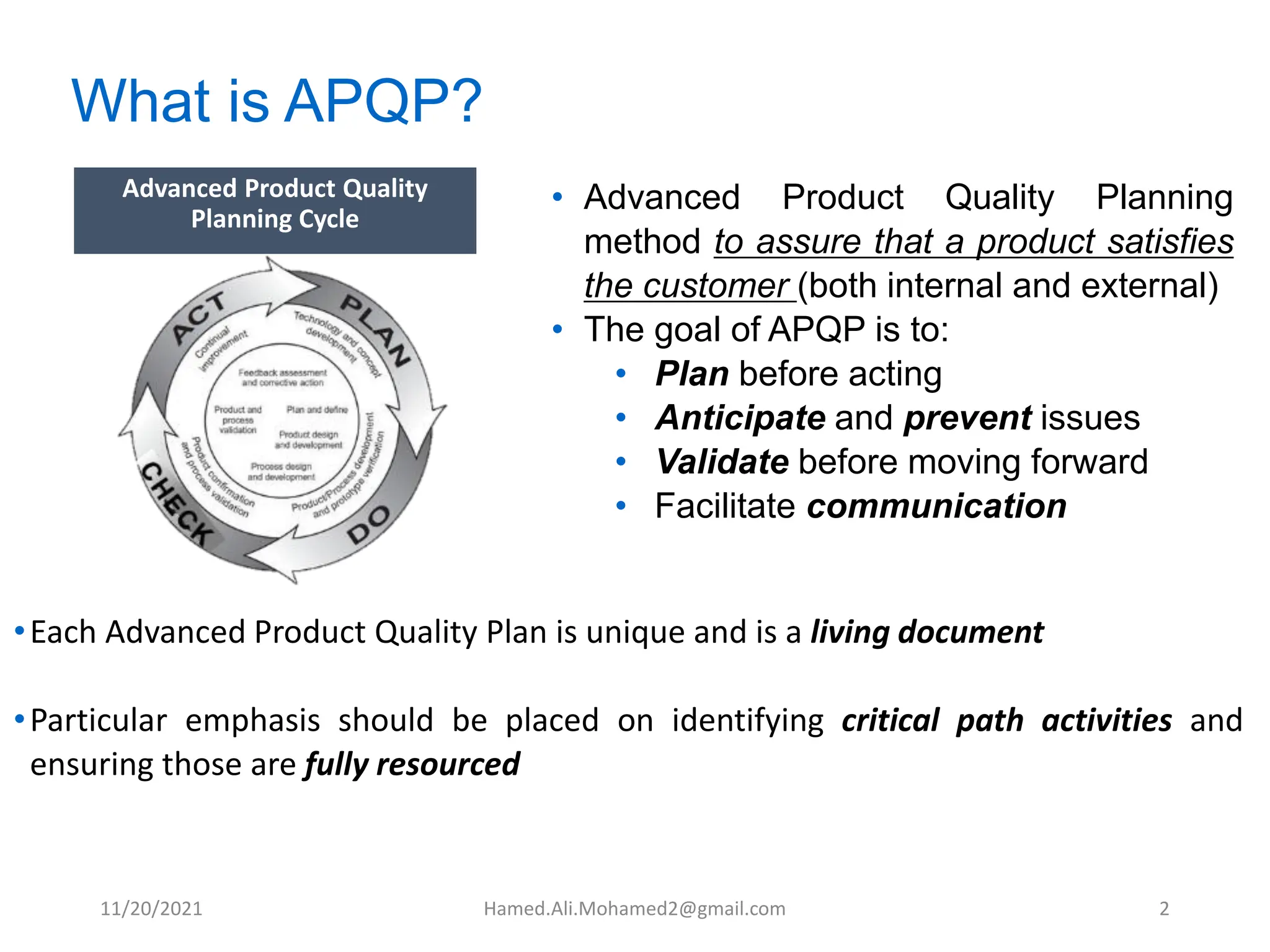

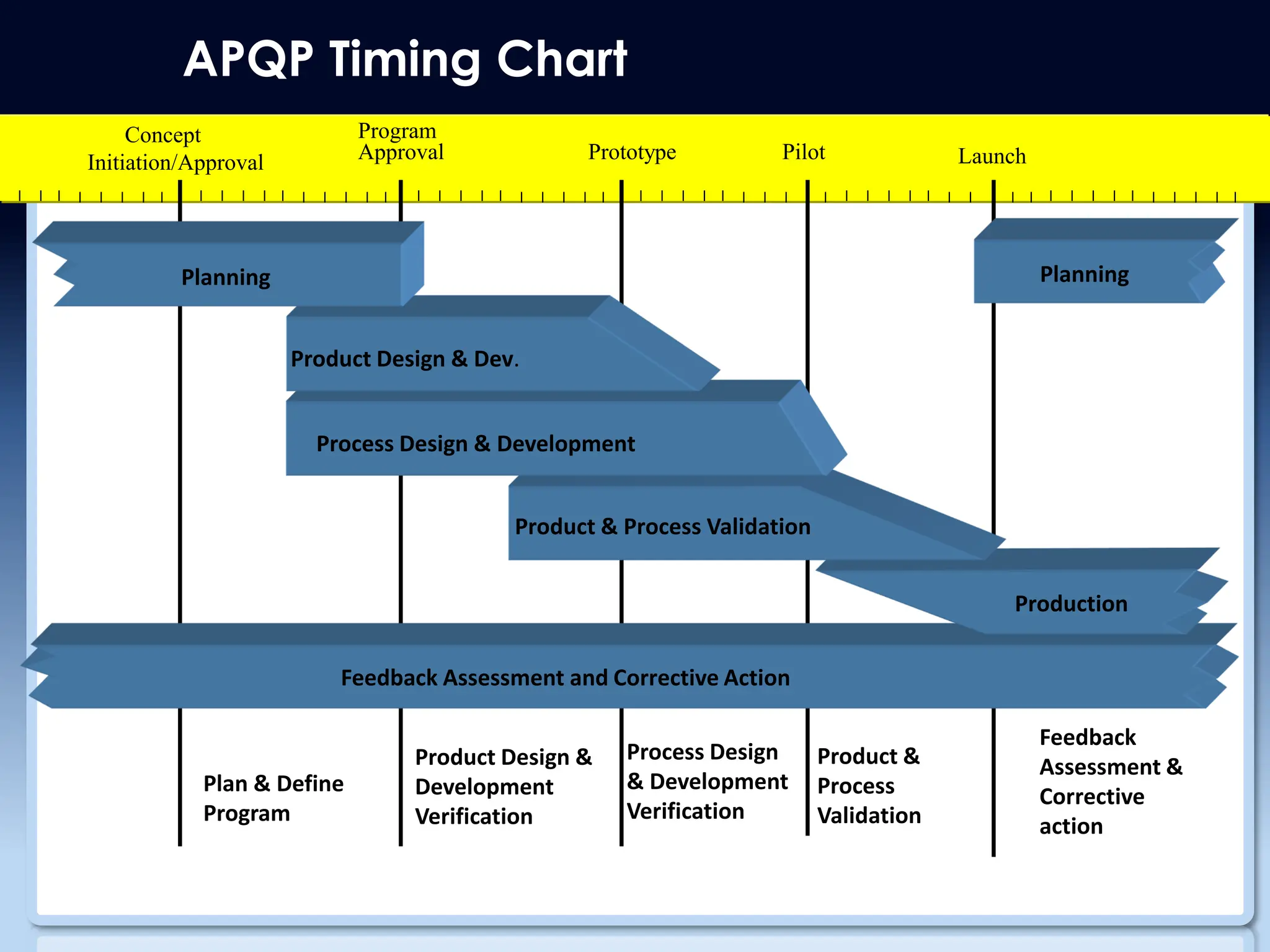

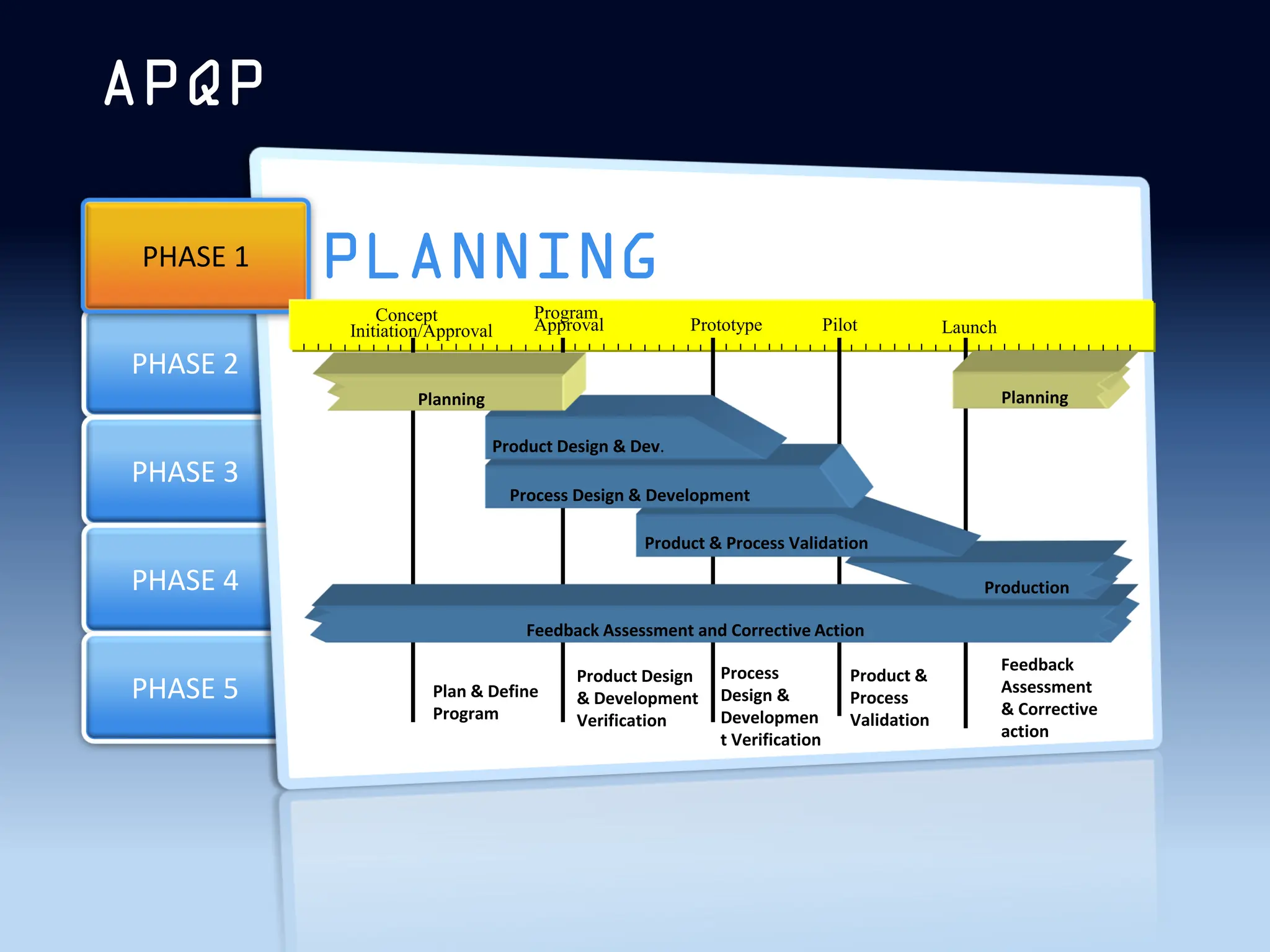

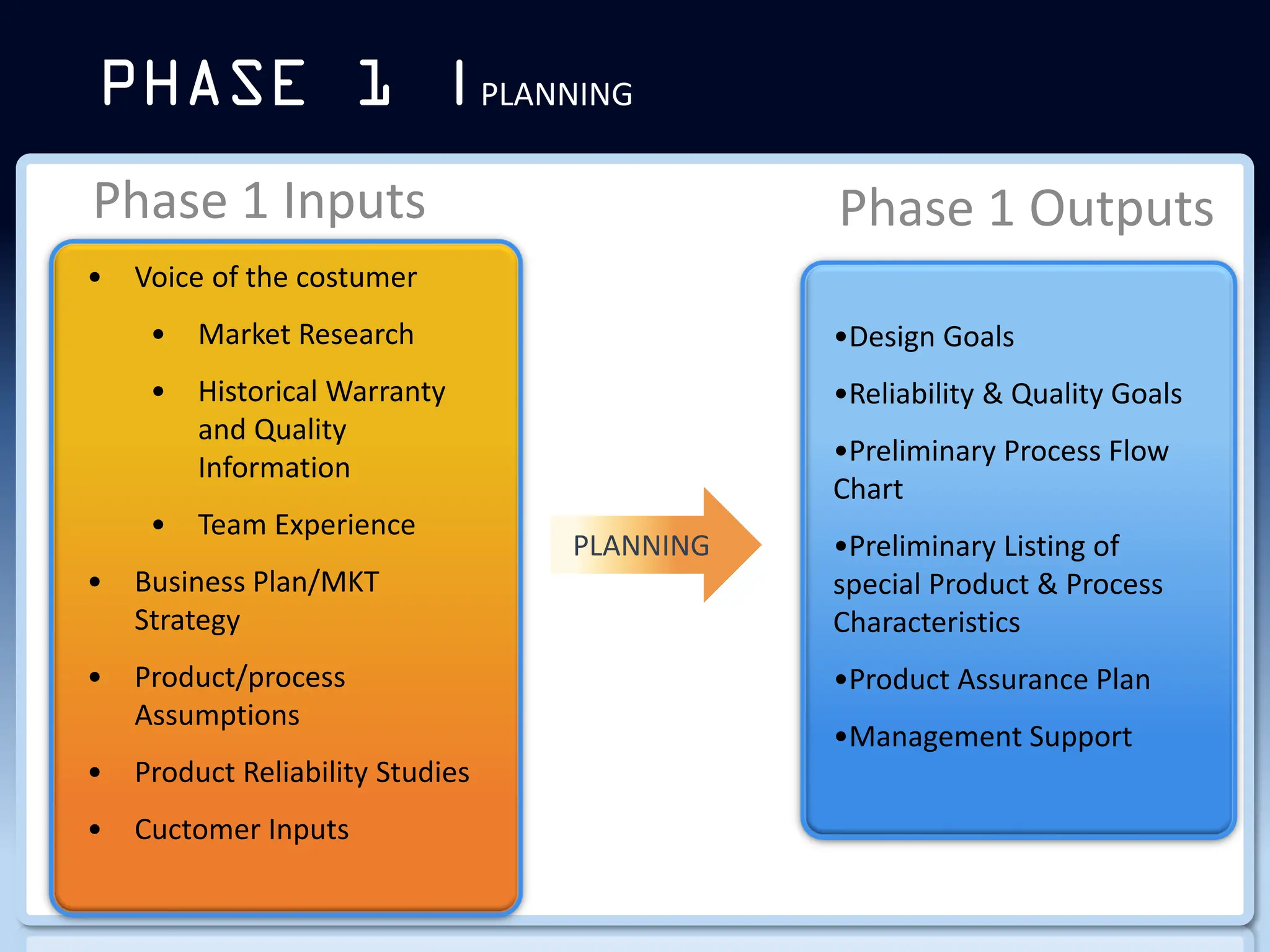

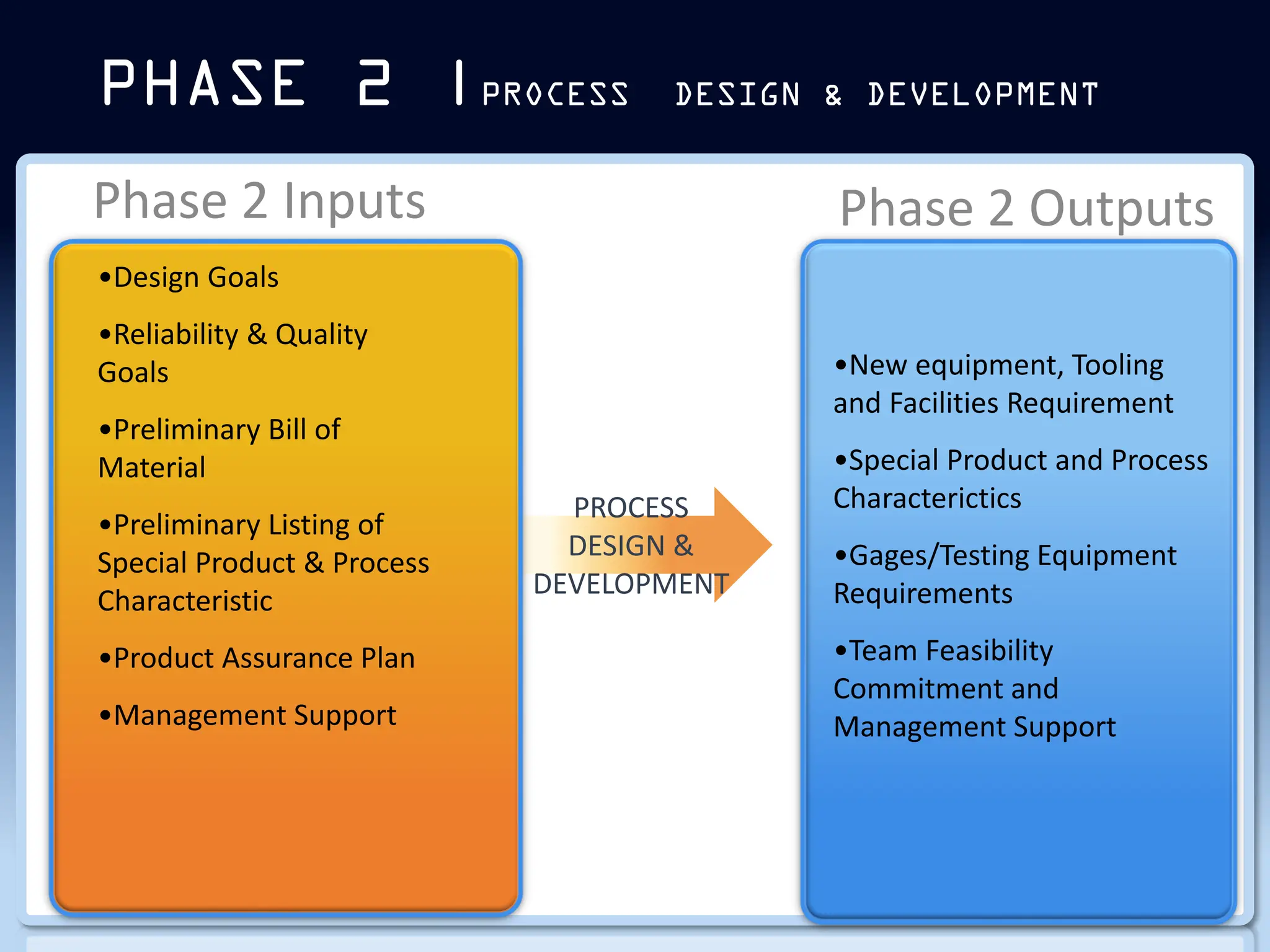

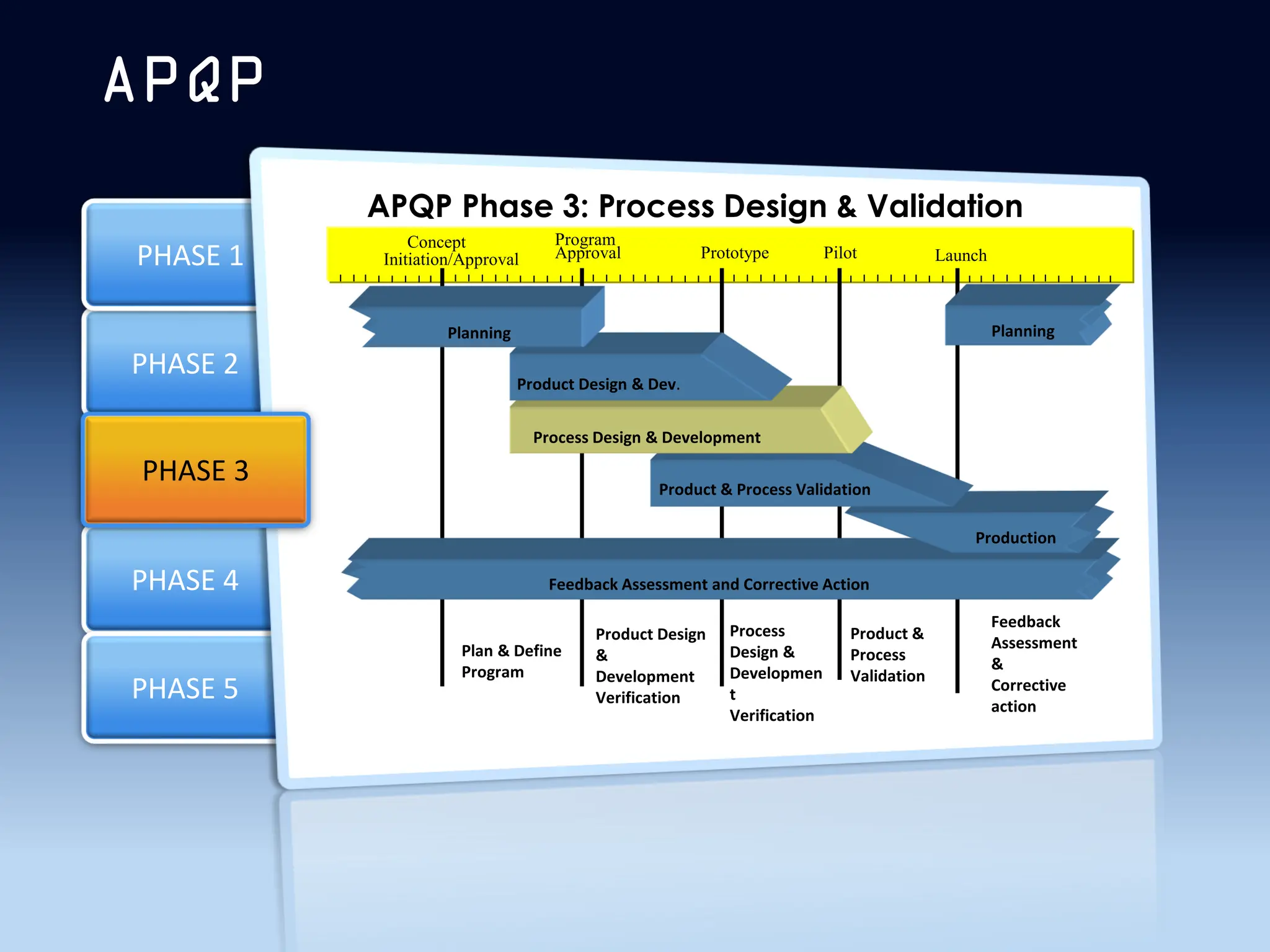

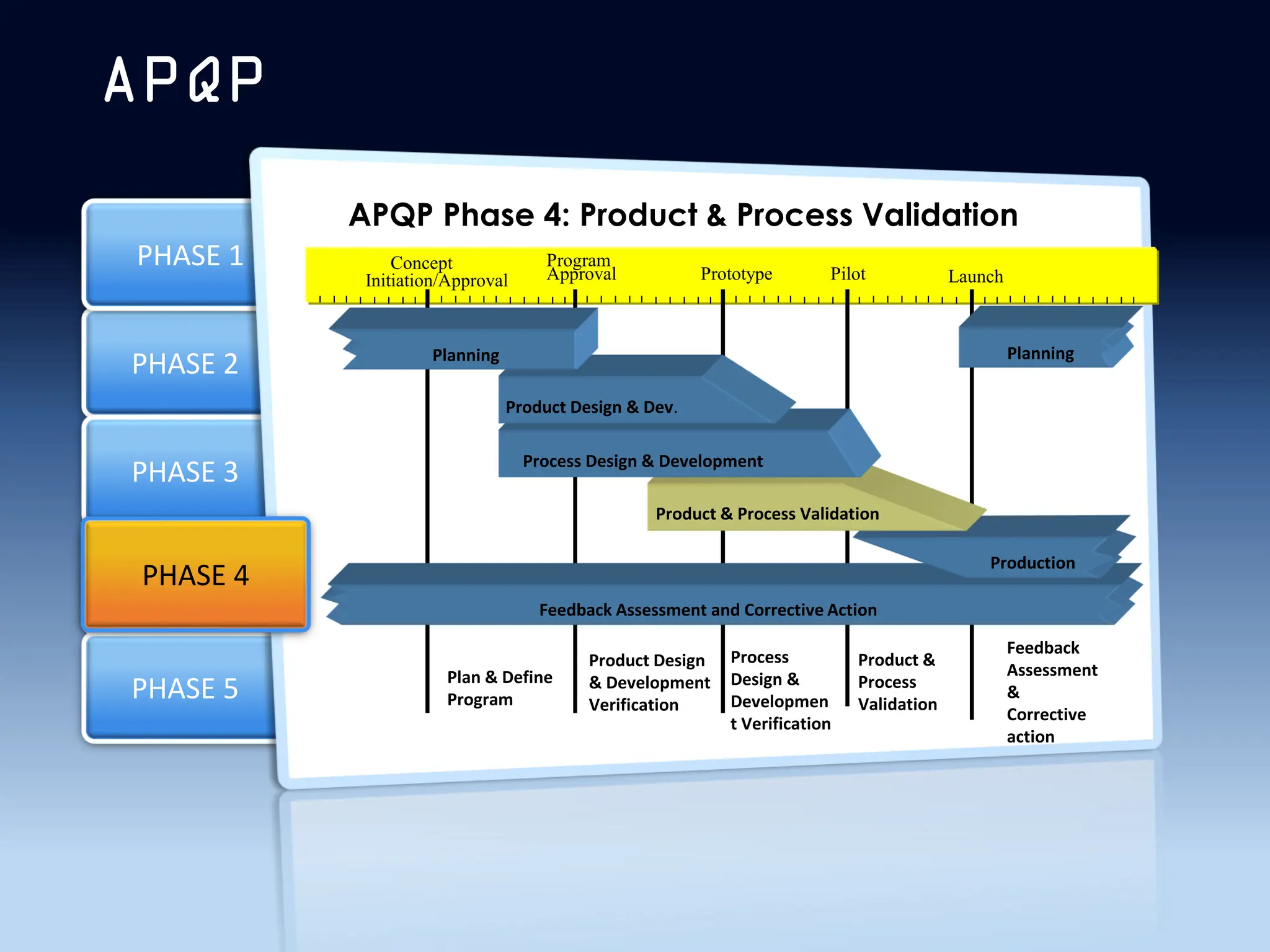

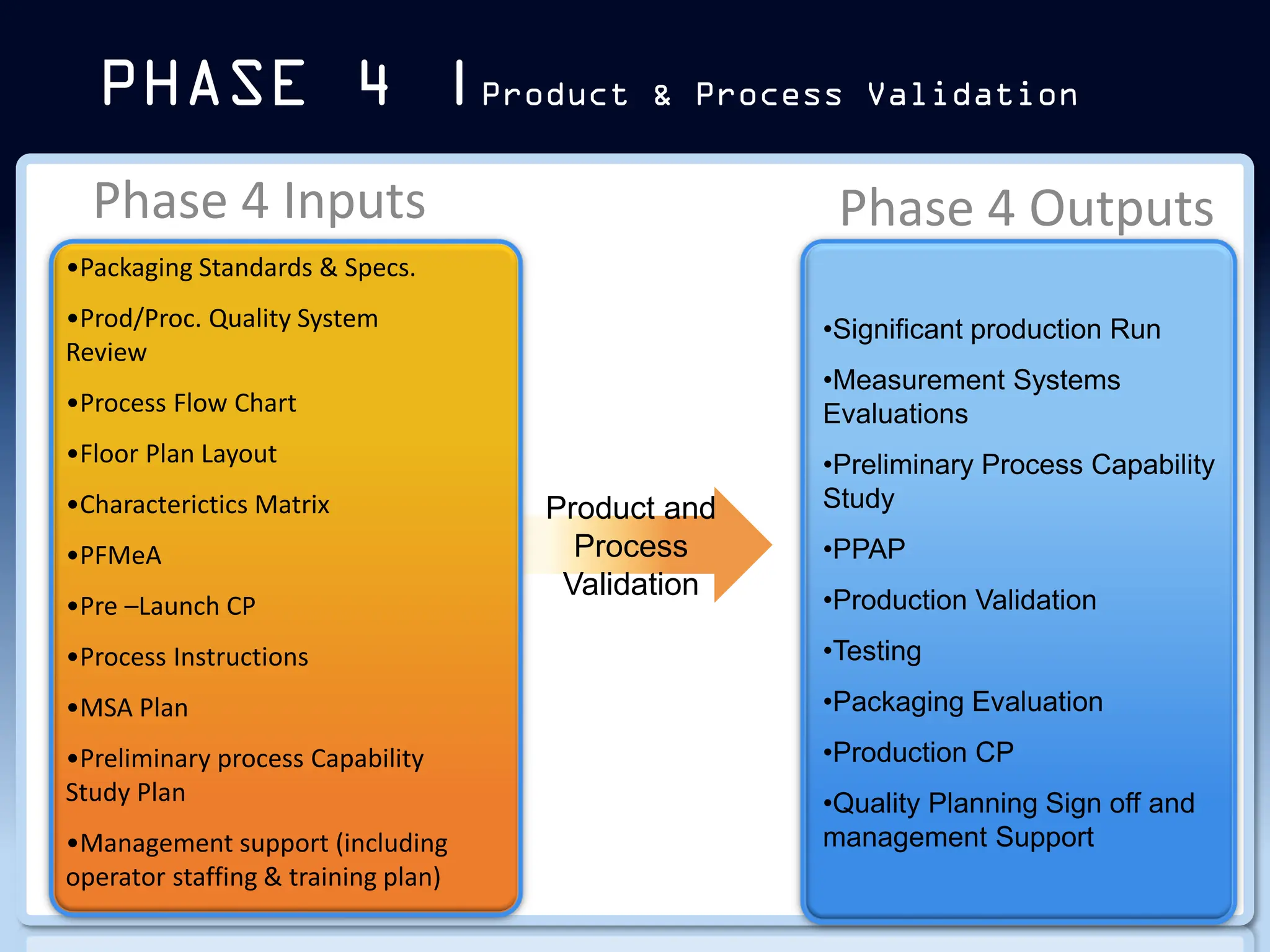

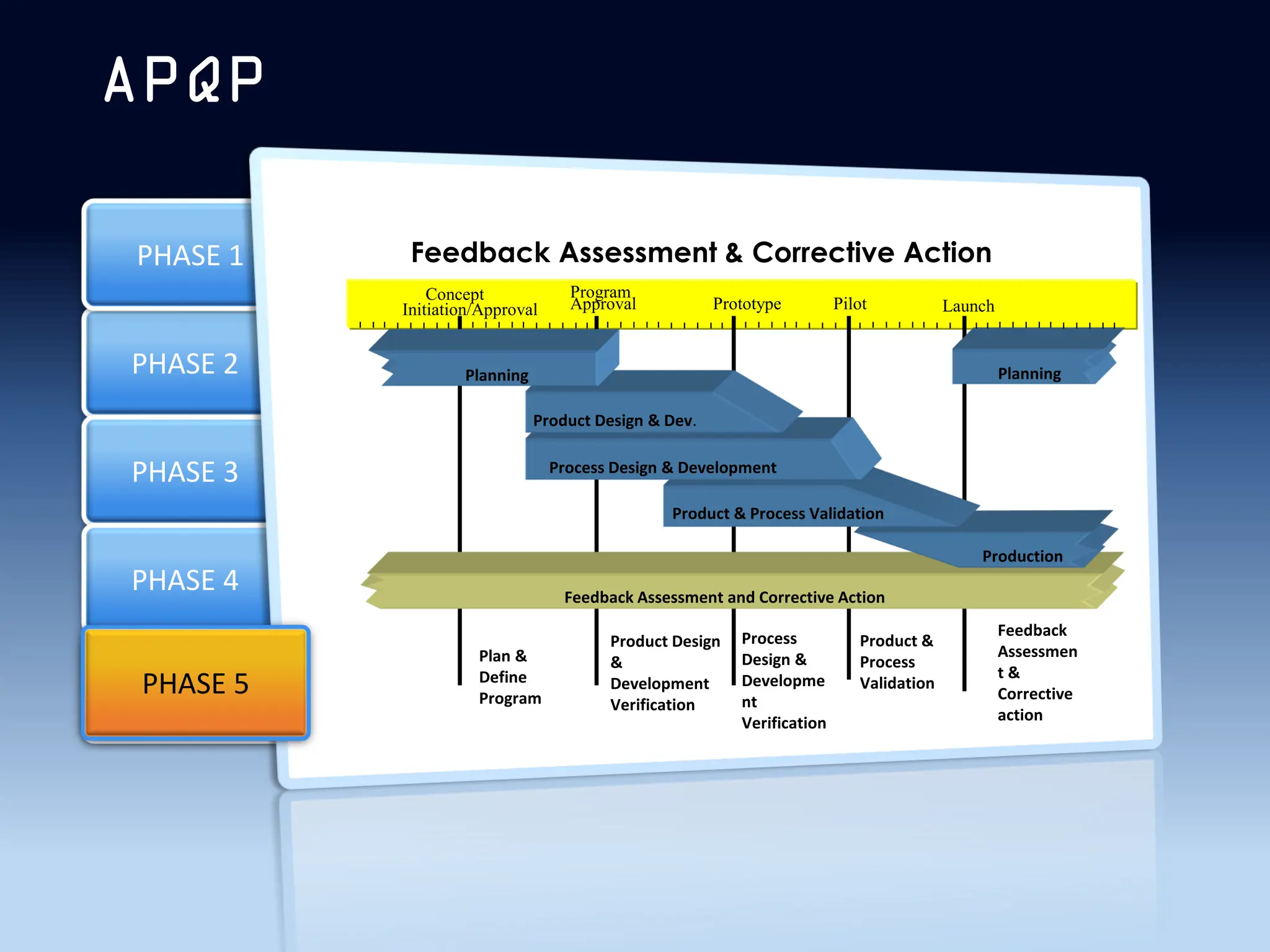

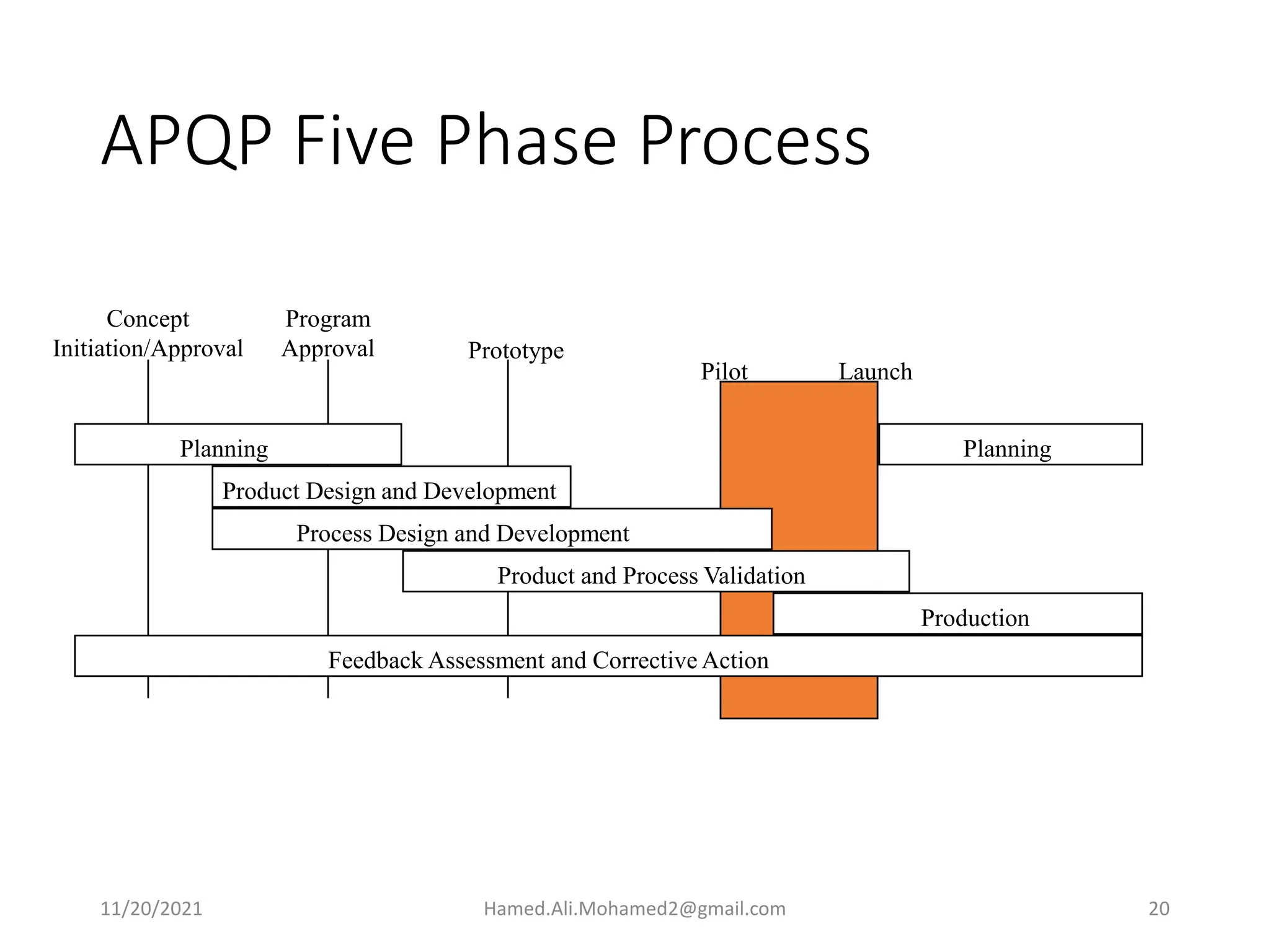

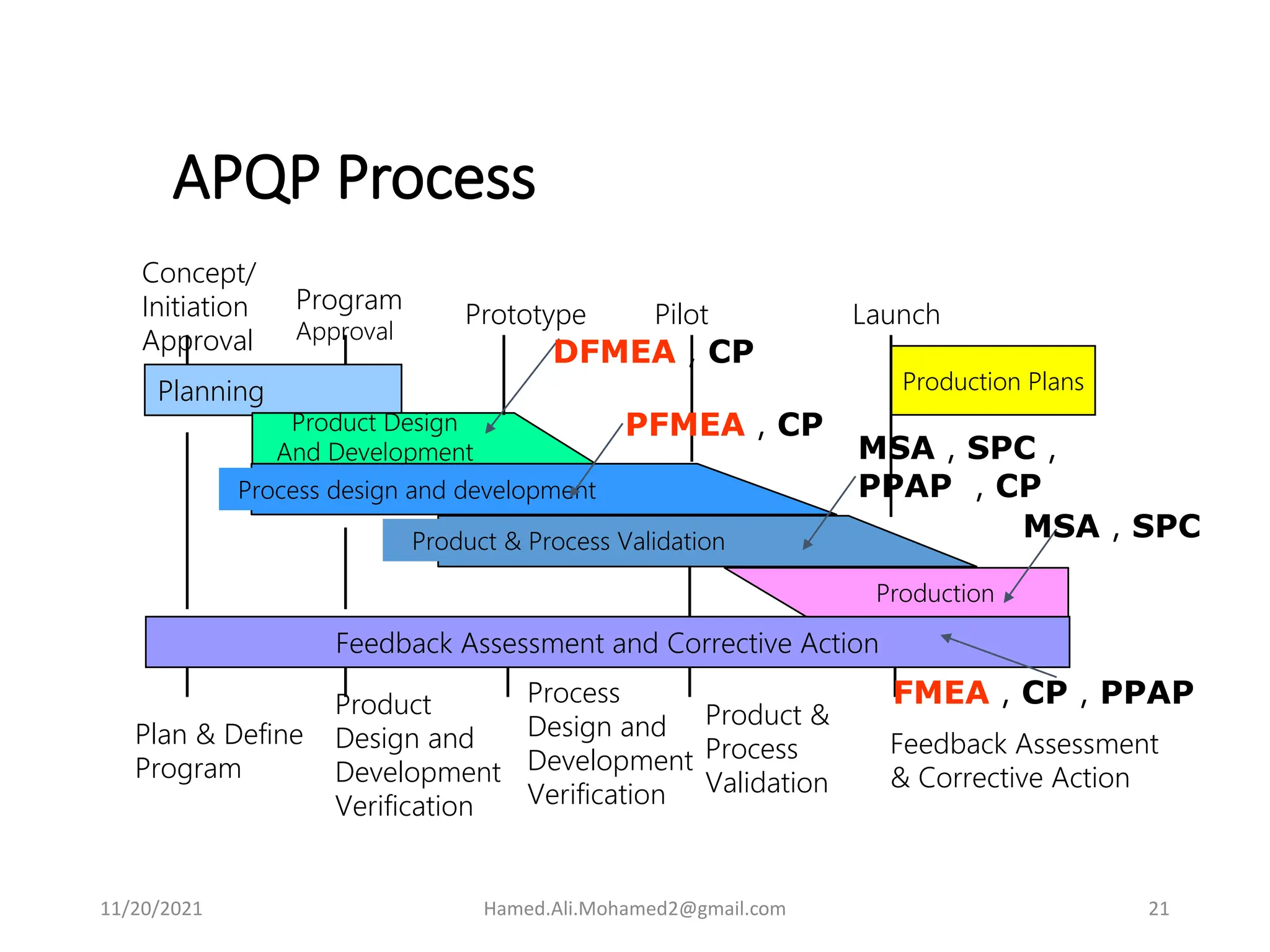

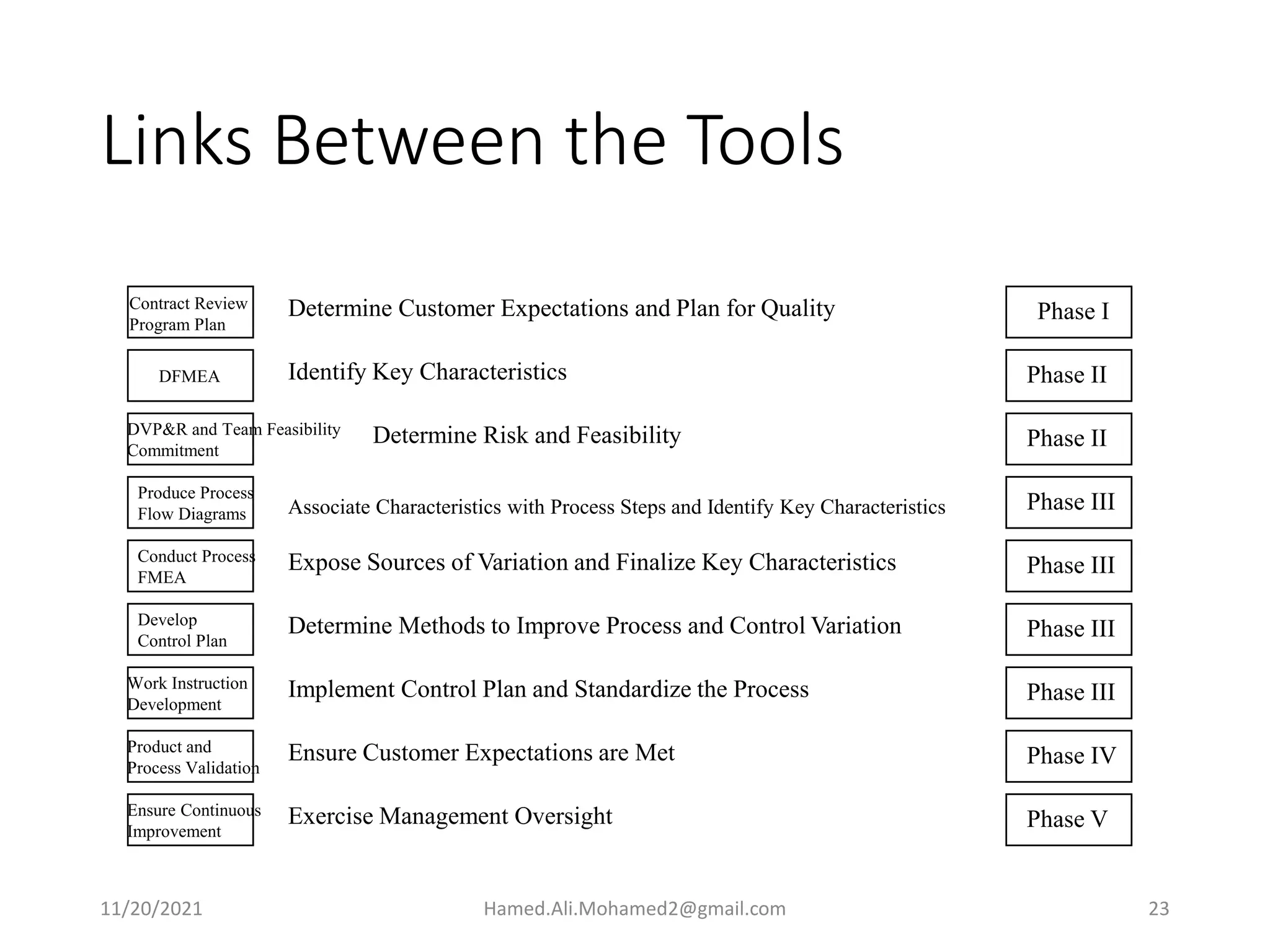

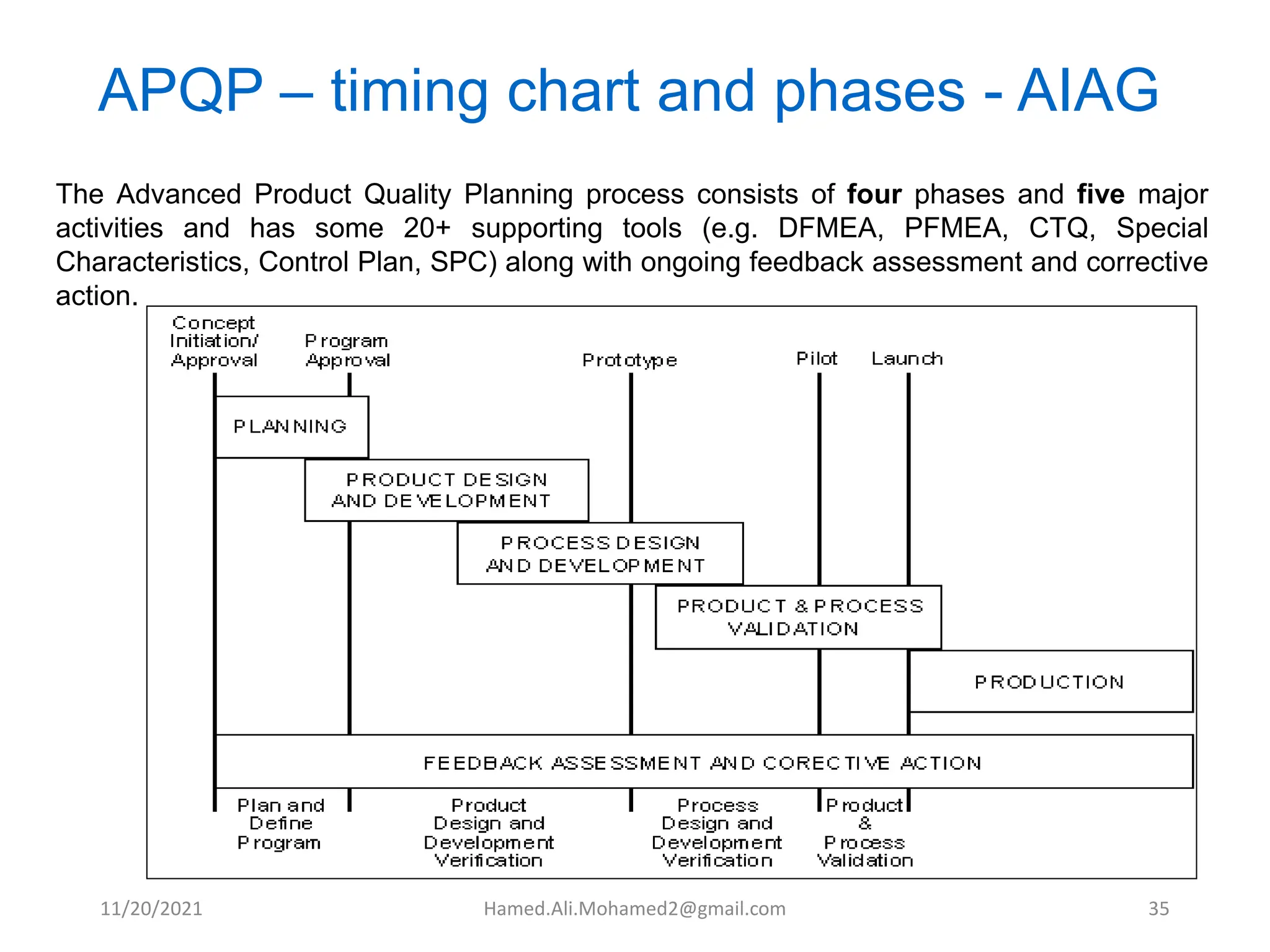

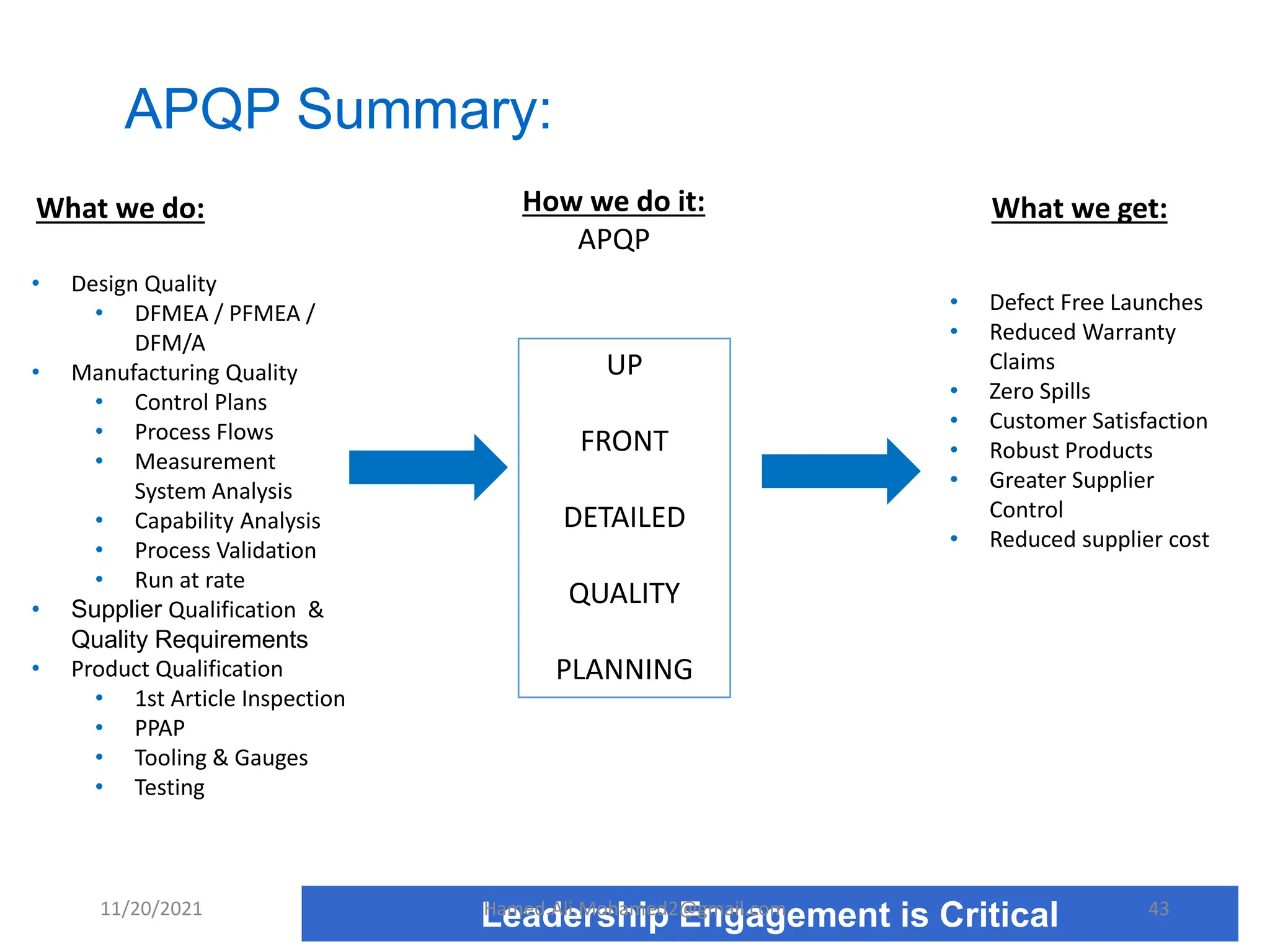

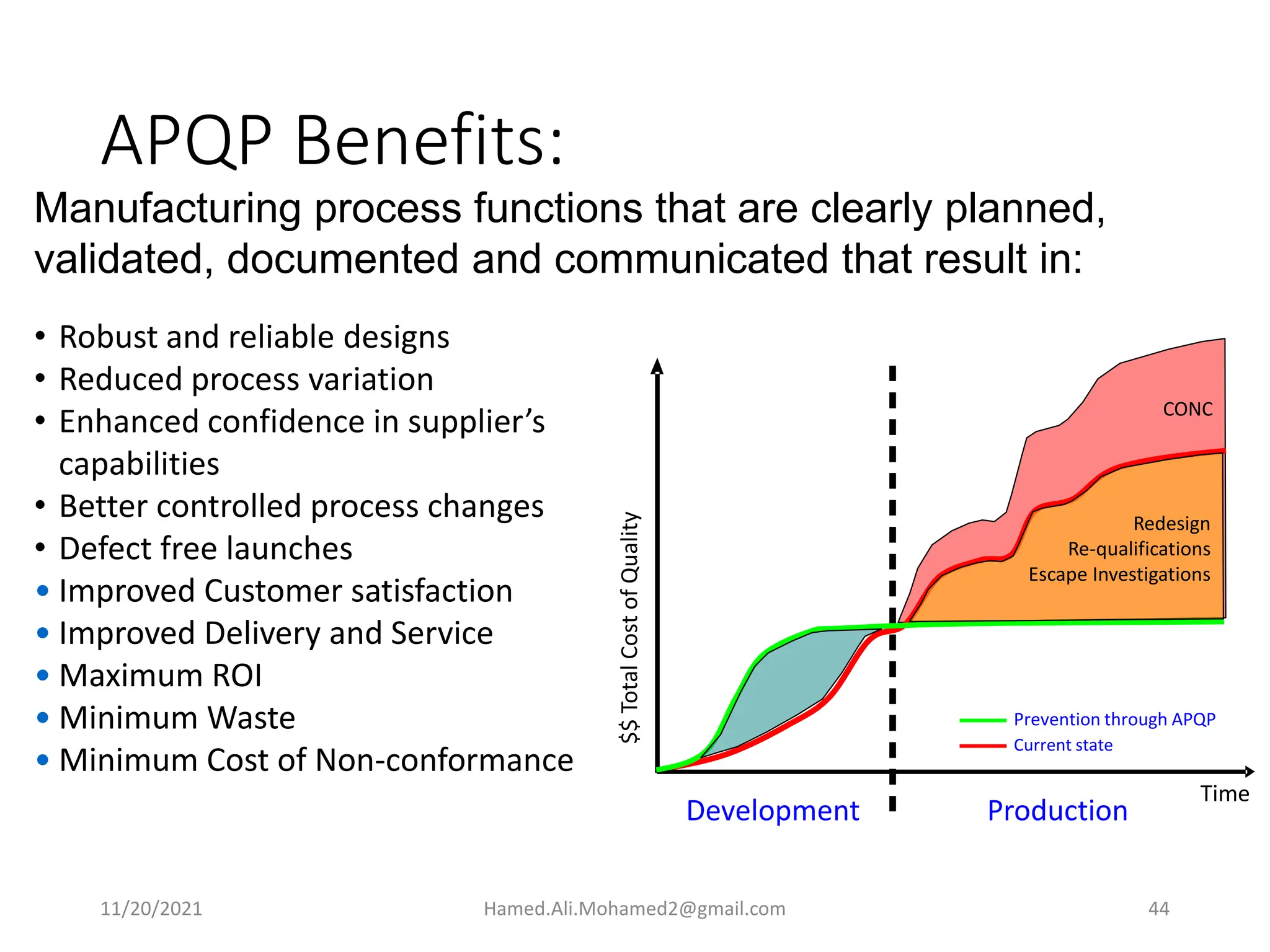

Advanced Product Quality Planning (APQP) is a methodology used to develop products and processes to help ensure they will meet customer requirements. It involves 5 phases - Planning, Product Design and Development, Process Design and Development, Product and Process Validation, and Production. The goal is to plan thoroughly at each stage, address potential issues proactively, and validate designs before production to facilitate communication and customer satisfaction.