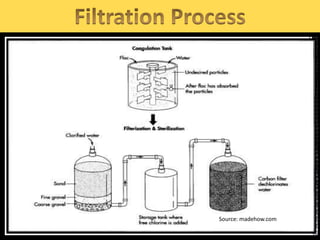

1. The manufacturing process for soft drinks involves carefully delivering, washing, mixing, blending, filling, labeling, inspecting, packaging, and distributing the raw ingredients which include high fructose corn syrup, sugar, artificial colorings, acids, and flavors.

2. Quality control is a high priority, with strict standards for water quality and regular microbiological testing. All ingredients, equipment, and facilities are carefully inspected, cleaned, and sanitized.

3. The company has installed new automated warehouse equipment to reduce costs, including storage and retrieval machines, conveyors, robotic vehicles, and packaging machines, allowing them to use 30% less space.