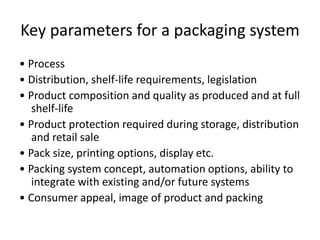

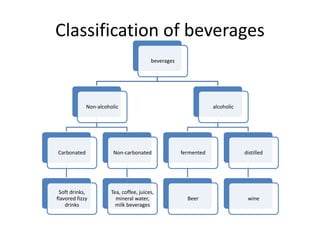

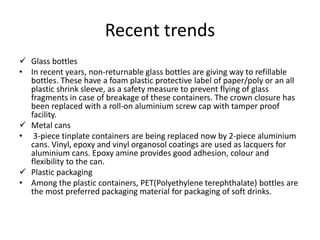

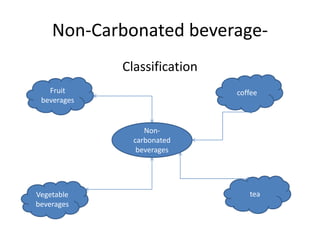

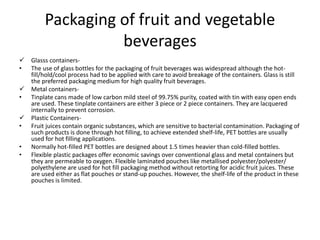

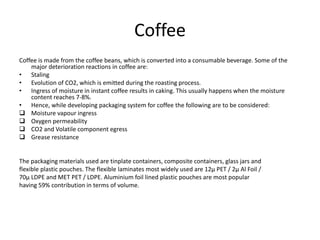

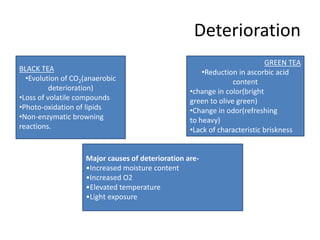

The document discusses packaging for the food and beverage industry. It defines food, beverages, and packaging. It then covers types of non-alcoholic beverages like carbonated beverages, fruit beverages, tea, and coffee. It discusses their packaging requirements to prevent deterioration like moisture, oxygen, and microbial growth. It also covers alcoholic beverages like beer, wine, and distilled spirits and their packaging in bottles or cans to prevent flavor loss and maintain quality. Overall, it examines the packaging needs of various food and drinks to protect quality during storage and distribution.