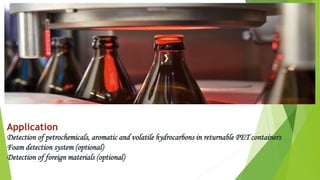

The document provides an overview of container inspection equipment used in the soft drink manufacturing process. It describes various types of inspection machinery that check bottles and cans for defects and contaminants at different stages of production like after filling, before packaging, and during the blow molding process. High-precision inspection equipment helps ensure product safety and quality while maximizing production output and efficiency.