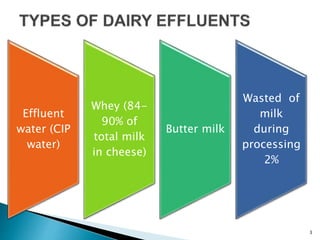

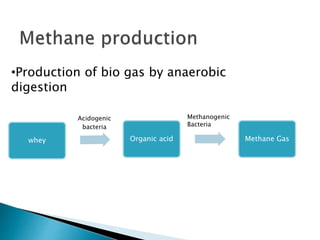

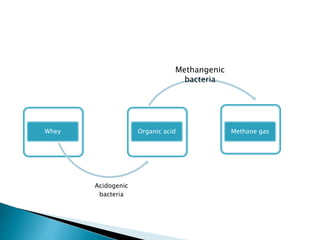

Pakistan is the 5th largest milk producer, but faces challenges in managing dairy effluents which have high biological and chemical oxygen demands. There is potential for reusing dairy waste, particularly through the production of single-cell protein and biogas from whey, which can be applied in animal feed. Additionally, whey and buttermilk by-products offer high nutritional value and functional properties, making them suitable for various food applications.