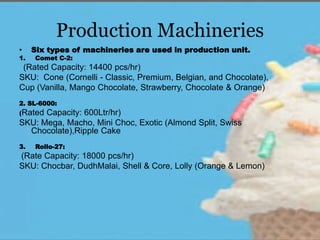

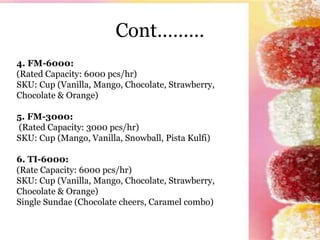

The document provides an overview of Abdul Monem Limited's "Igloo Ice Cream and Milk Unit" including its production processes. It discusses Igloo's ice cream and milk production lines, quality control procedures, engineering, plastic, storage and human resources departments. Key details include Igloo producing over 100 ice cream varieties daily using specialized machinery, producing milk products, and maintaining quality standards through certifications and testing at various stages of the process.