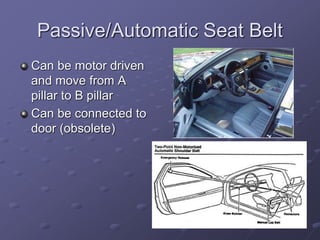

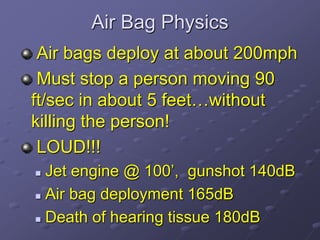

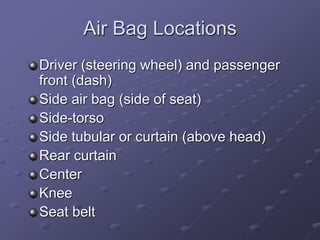

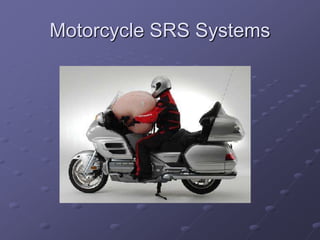

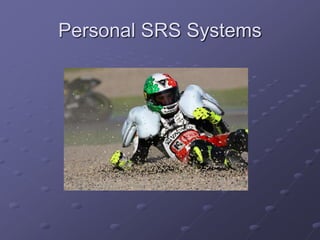

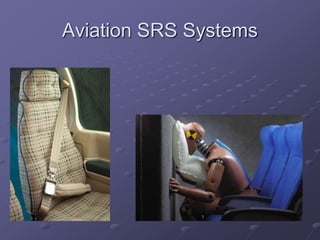

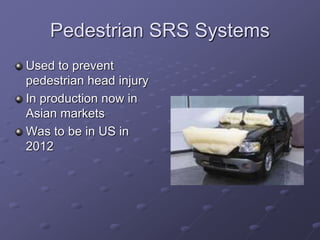

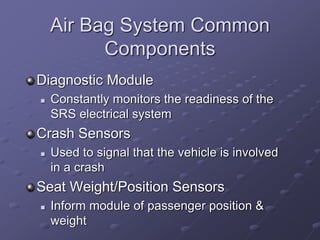

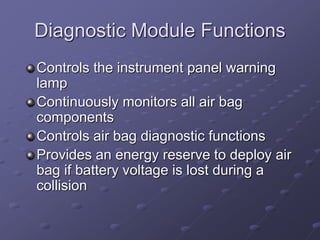

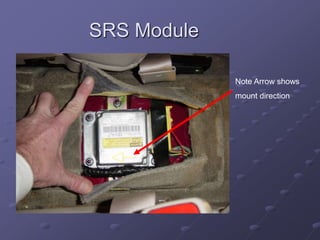

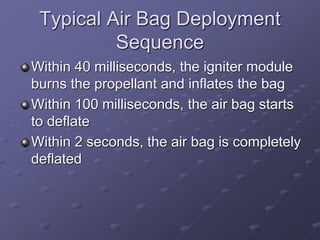

Passive restraint systems like airbags and seatbelts were developed in the 1970s and required by law in the late 1980s to protect unbelted passengers. Airbags deploy at around 200mph to stop occupants moving at high speeds without killing them. Supplemental restraint systems (SRS) like airbags supplement seatbelts and require them to be buckled for effective protection. SRS components include airbags, sensors, an diagnostic module that monitors readiness and controls airbag deployment. Upon crash detection, airbags inflate within 40 milliseconds to cushion occupants.