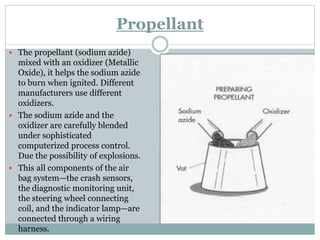

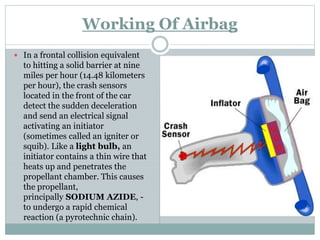

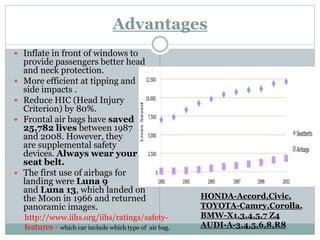

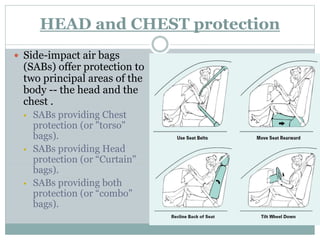

The document provides a comprehensive overview of airbags, detailing their history, components, and functioning. It explains the mechanics of airbag deployment during collisions, highlights advantages such as improved occupant safety, and acknowledges disadvantages including potential harm to individuals too close to deploying airbags. Future advancements in airbag technology, including hybrid inflators and smart sensors for occupant detection, are also discussed.