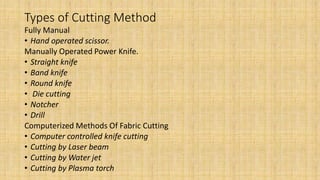

Shakib Khan presented on computerized cutting machines. He discussed that cutting is a necessary step in garment production to separate fabric pieces according to a marker. There are manual, semi-automatic, and computerized cutting methods. Computerized knife cutting machines cut fabric according to a computer program without needing a marker, using an oval steel blade that moves precisely. Laser beam cutting machines cut fabric using a high-powered laser beam in a fine spot, controlled by a computer, cutting at 13 meters per minute. Computerized cutting machines provide accurate, high-speed cutting but have high initial and maintenance costs and require skilled operators.