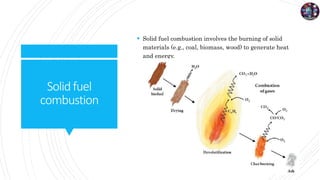

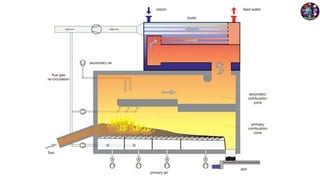

The document discusses solid fuel combustion methods, focusing on fixed bed combustion and grate furnaces that involve burning solid materials like coal and biomass to generate heat and energy. It highlights the advantages such as simple operation, ability to burn various fuels, and suitability for medium-scale applications, as well as challenges related to fuel preparation and air distribution. Applications of these combustion systems include industrial boilers, power generation plants, and heating systems.