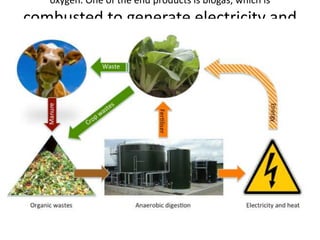

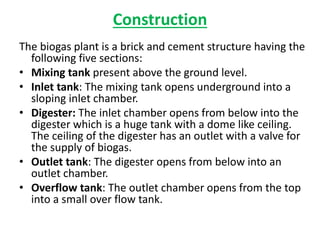

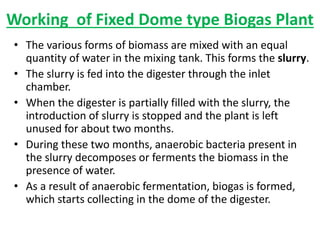

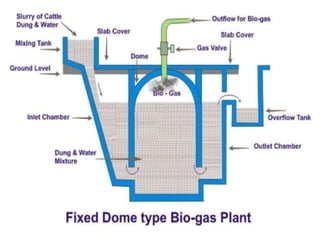

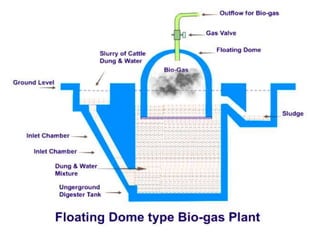

Anaerobic digestion is a process where microorganisms break down biodegradable material in the absence of oxygen to produce biogas, a clean and efficient fuel composed primarily of methane. There are two main types of biogas plants - fixed dome and floating gas holder. Both use biomass and water inputs and anaerobic digestion to produce biogas, which can then be used for electricity, heat, transportation fuel or grid injection. Biogas is a renewable and carbon-neutral energy source that provides environmental benefits over fossil fuels while generating nutrient-rich fertilizer as a byproduct.