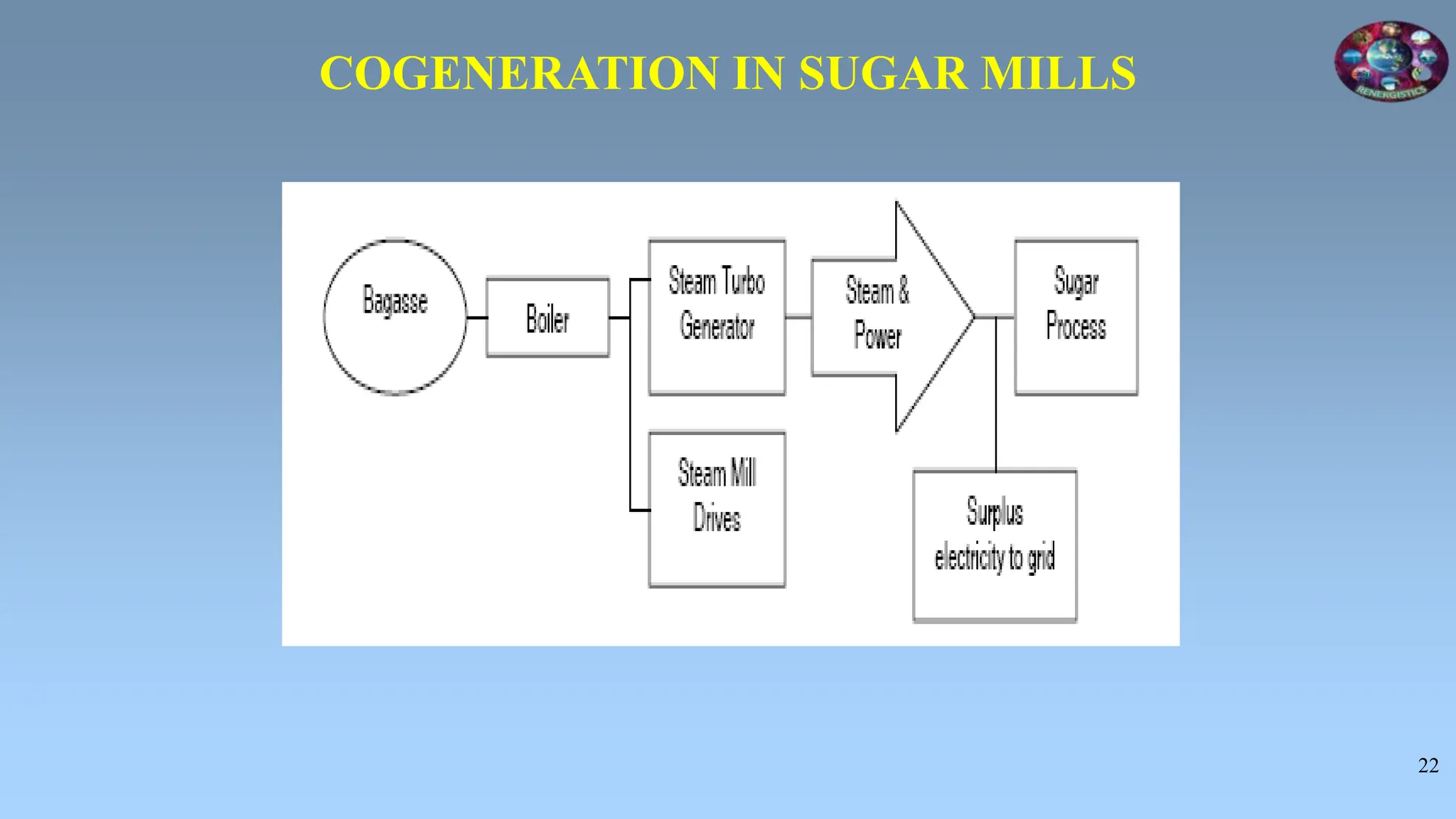

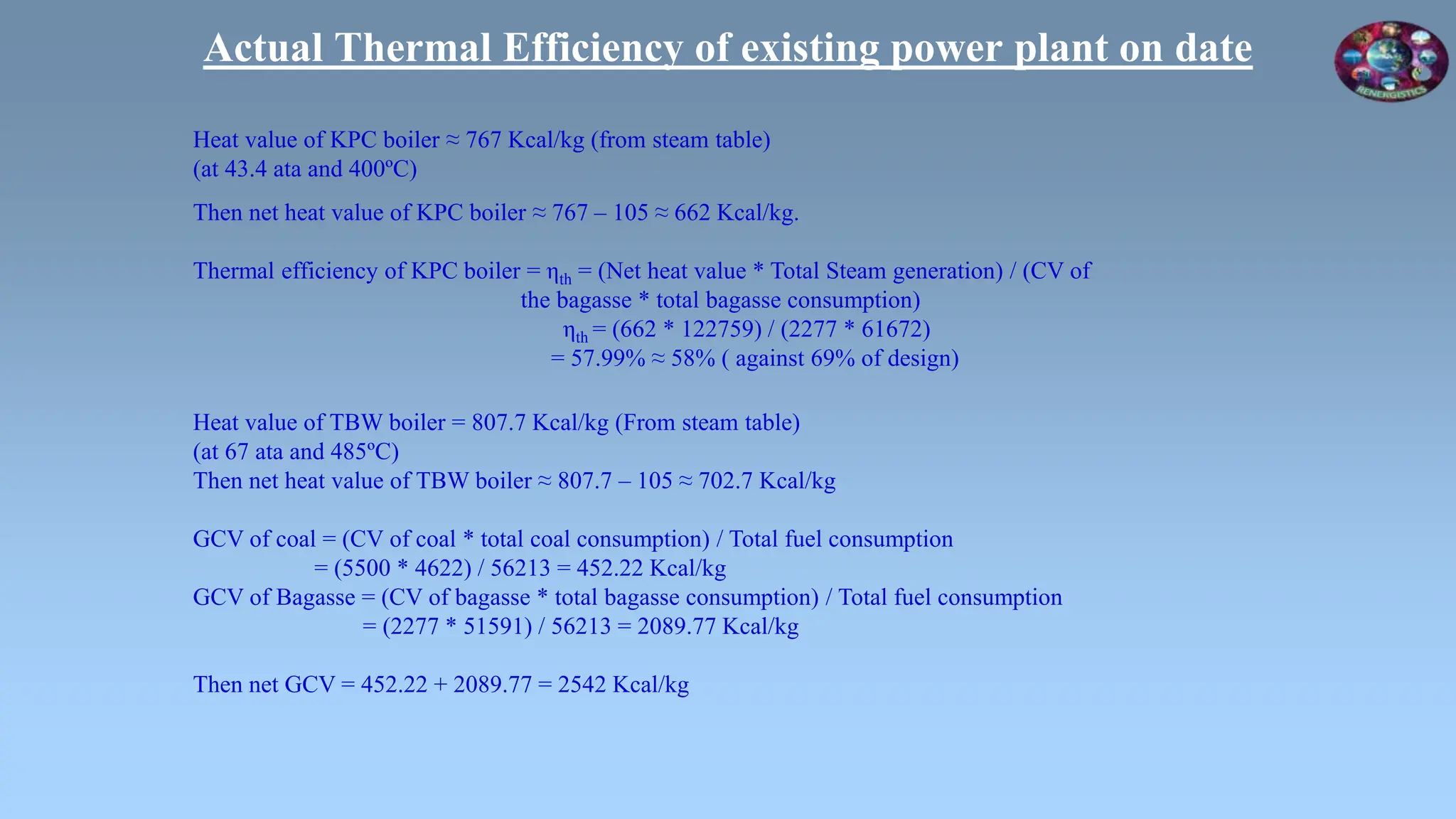

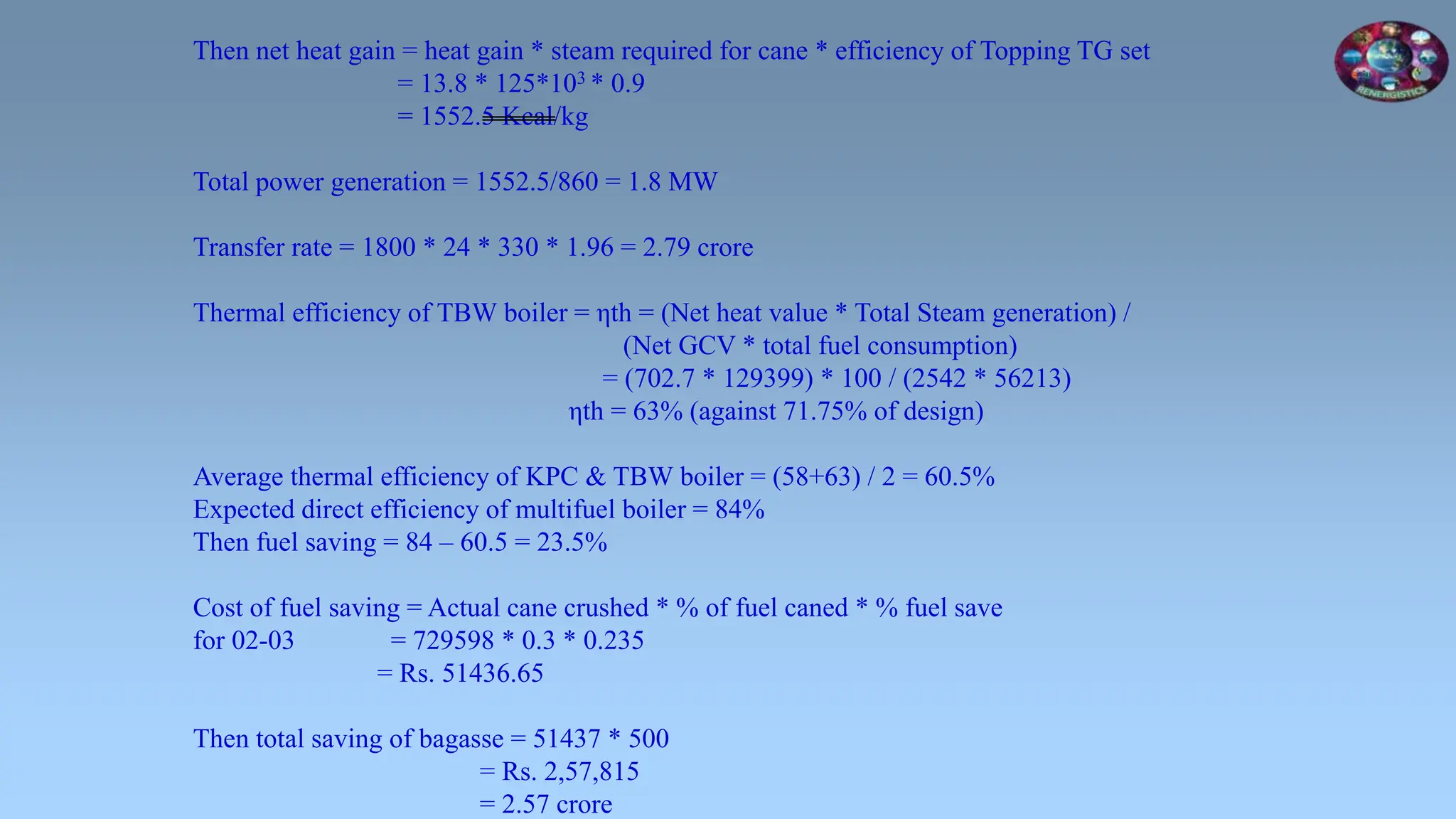

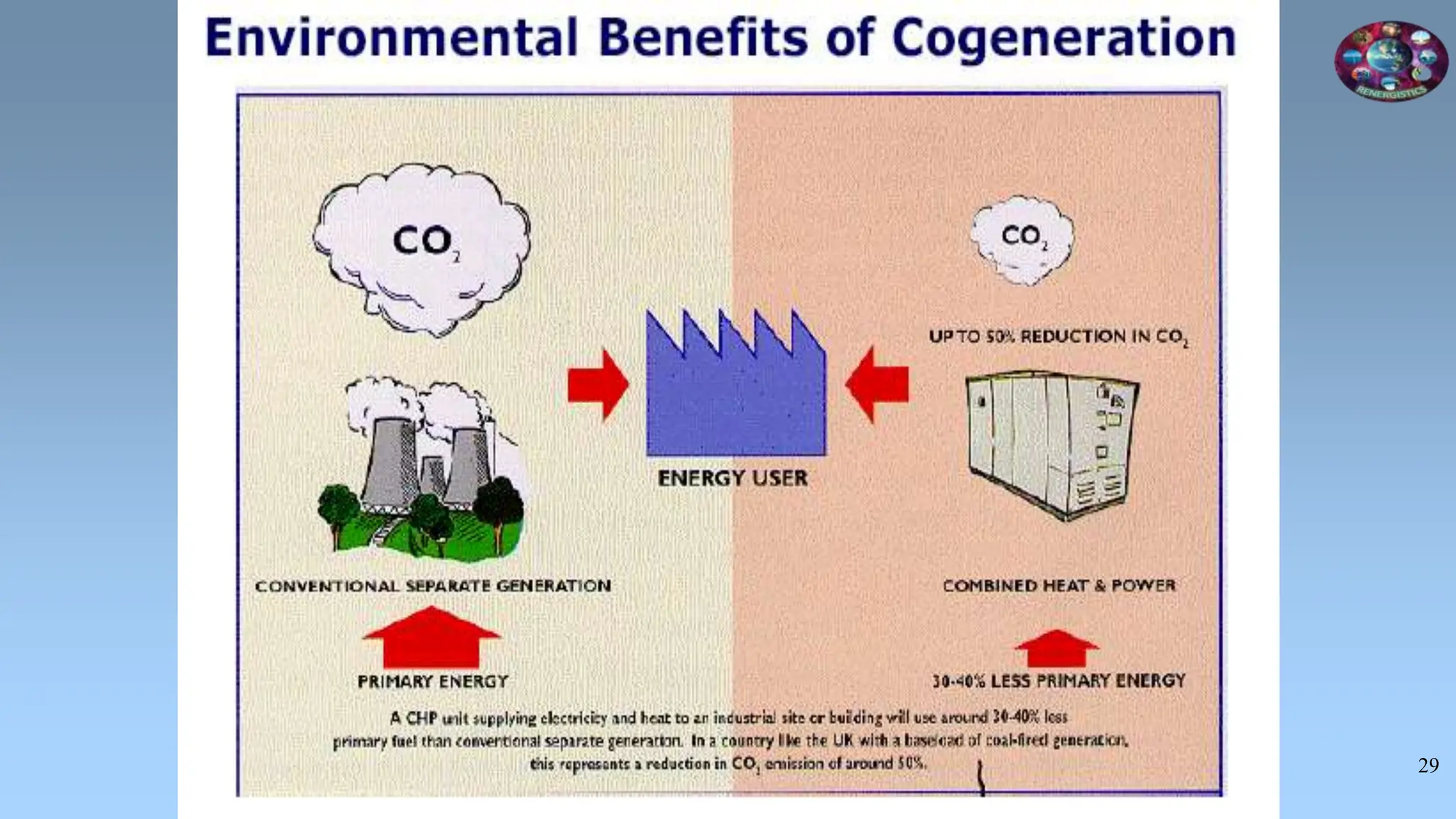

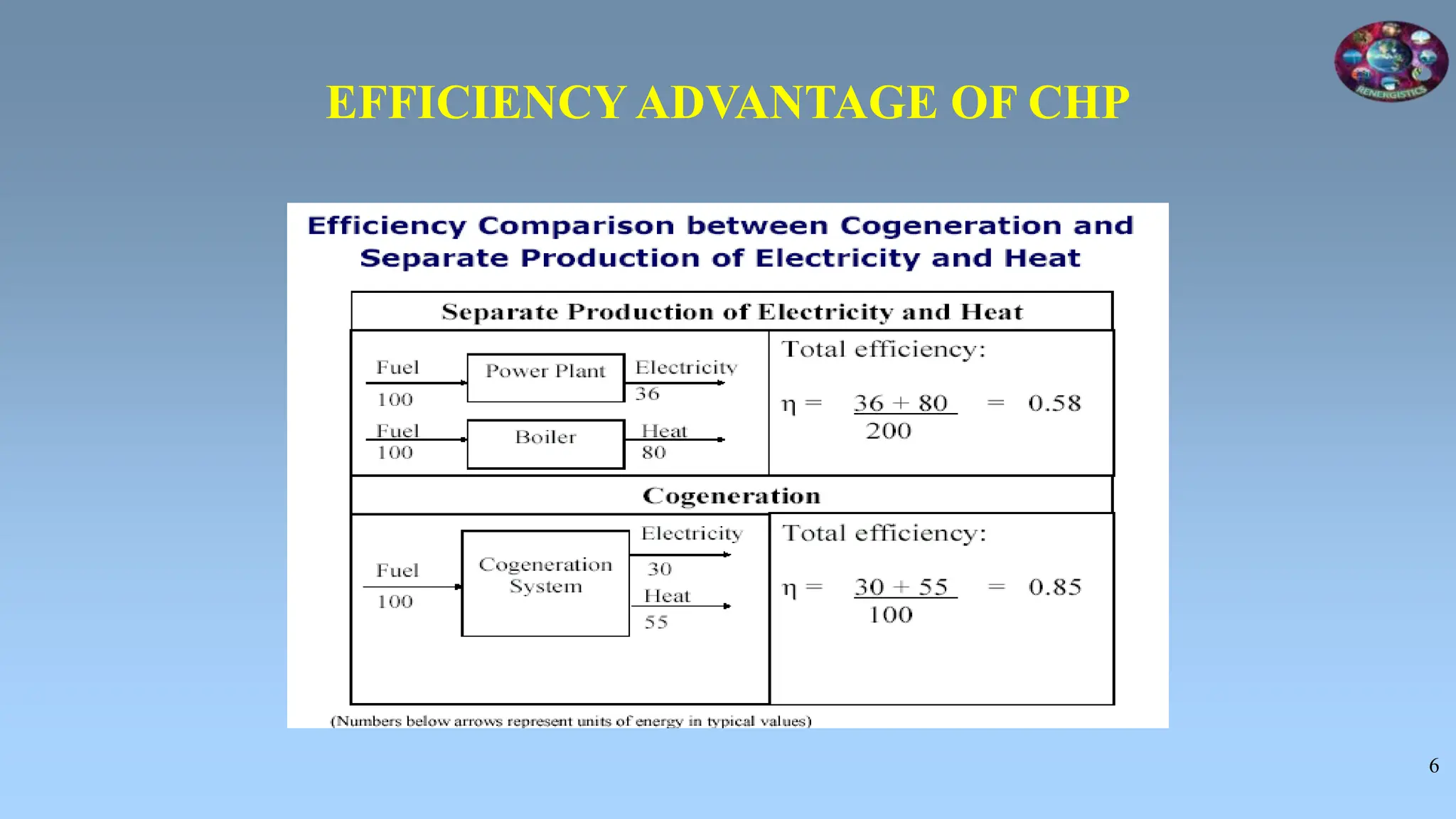

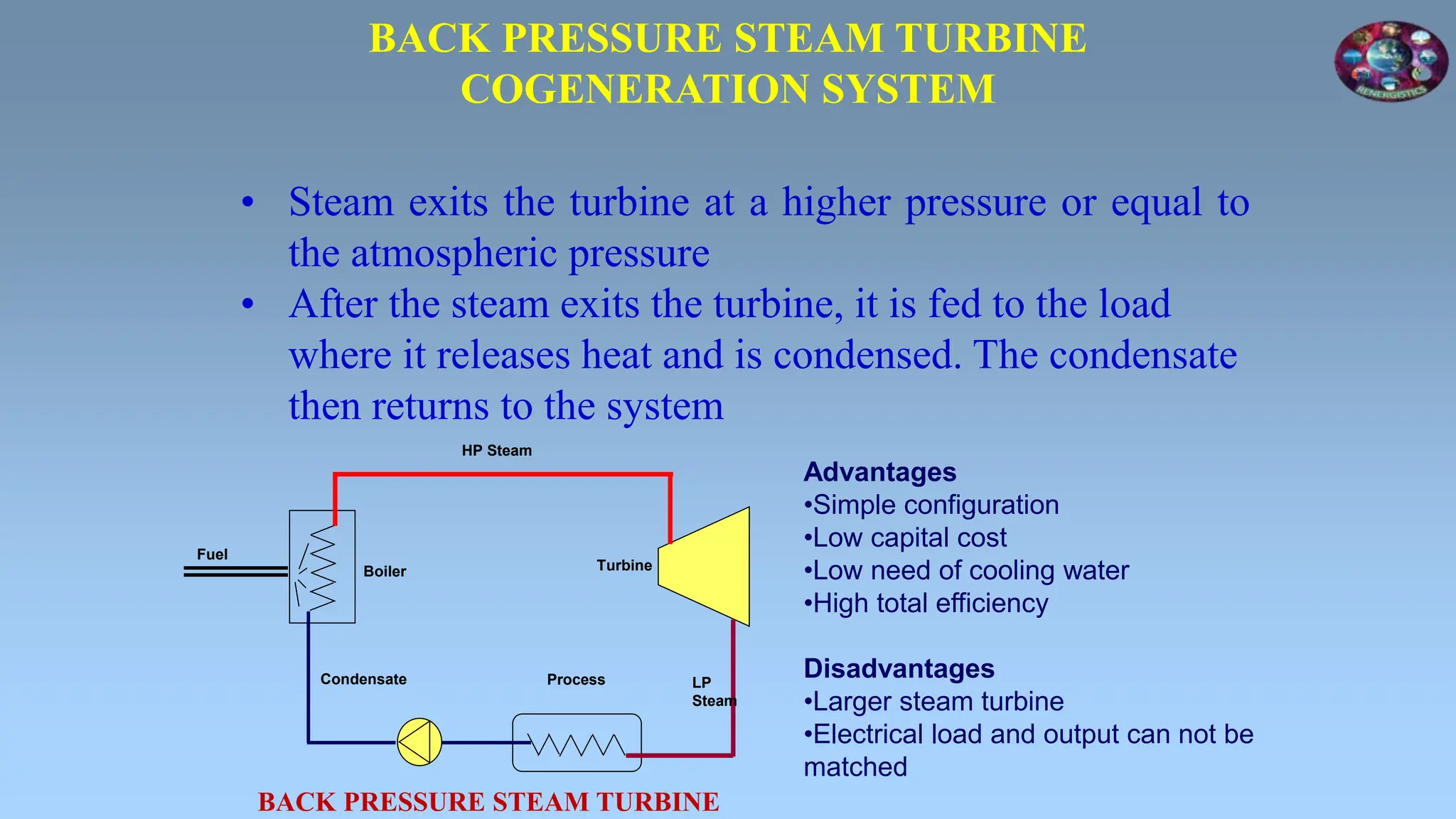

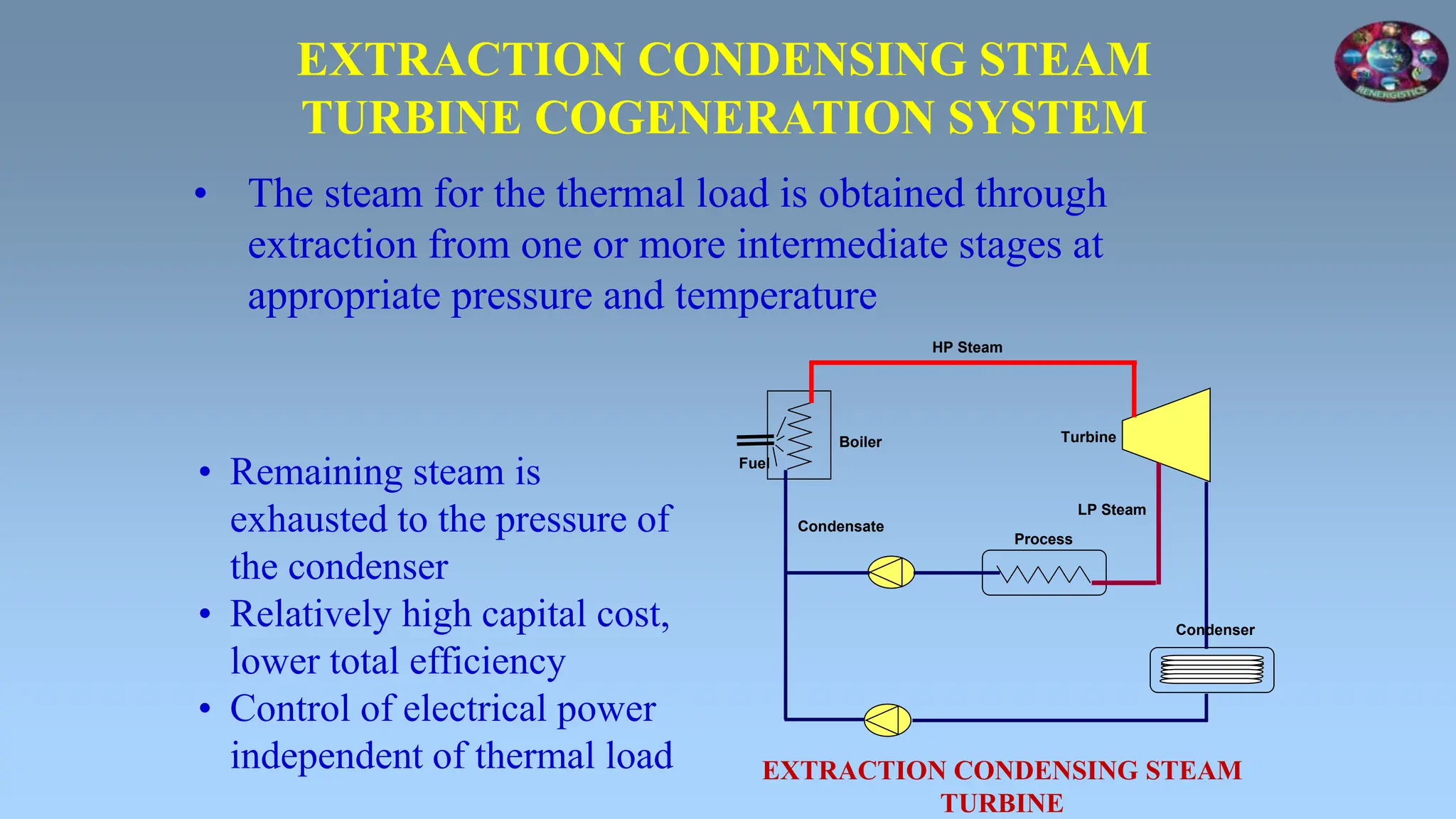

The document discusses cogeneration, the simultaneous production of power and heat, emphasizing its efficiency, economic advantages, and environmental benefits. It details various technologies and systems used in cogeneration, including different prime movers and operational cycles, while comparing their efficiencies and applications. Additionally, it highlights specific case studies, particularly in sugar mills, to demonstrate potential energy and fuel savings.

![18

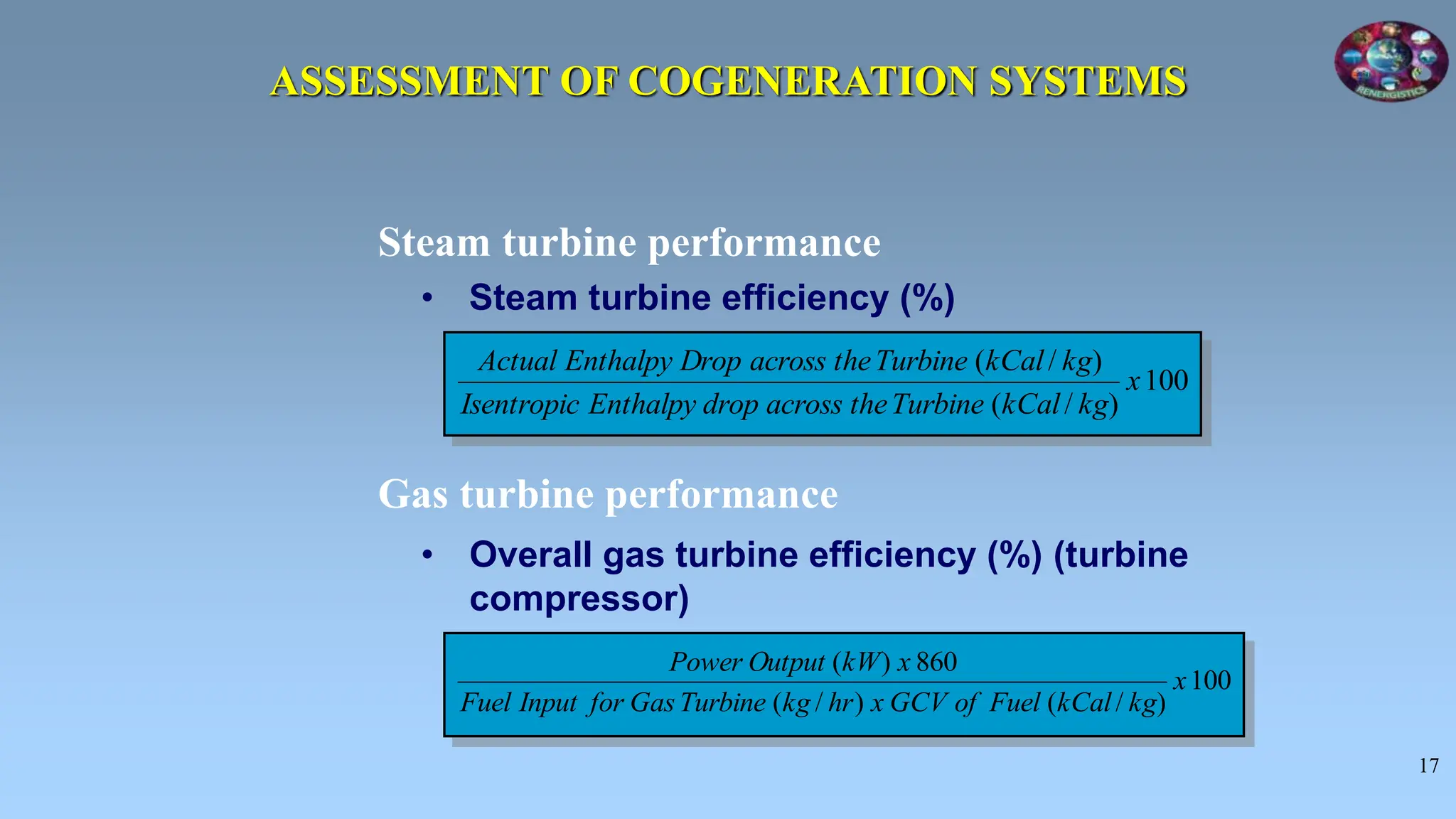

• Heat recovery steam generator efficiency (%)

Ms = Steam Generated (kg/hr)

hs = Enthalpy of Steam (kCal/kg)

hw = Enthalpy of Feed Water (kCal/kg)

Mf = Mass flow of Flue Gas (kg/hr)

t-in = Inlet Temperature of Flue Gas (0C)

t-out = Outlet Temperature of Flue Gas (0C)

Maux = Auxiliary Fuel Consumption (kg/hr)

Heat Recovery Steam Generator (HRSG) Performance

100

)]

/

(

[

)]

(

[

)

(

x

kg

kCal

Fuel

of

GCV

x

M

t

t

Cp

x

M

h

h

x

M

aux

out

in

f

w

s

s

ASSESSMENT OF COGENERATION SYSTEMS](https://image.slidesharecdn.com/lec25-240407162029-58d683e8/75/Cogeneration-and-its-basics-for-energy-management-18-2048.jpg)