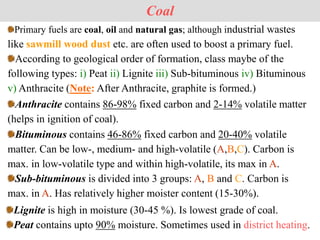

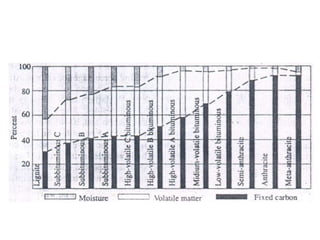

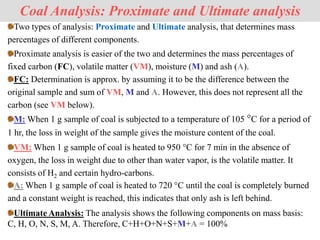

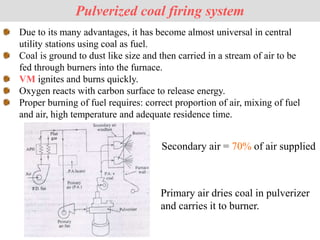

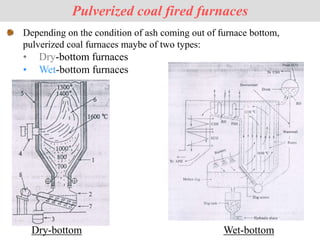

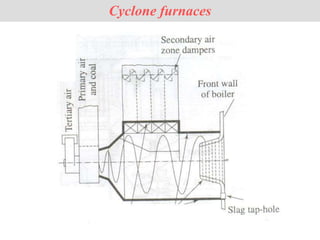

Primary fuels are coal, oil and natural gas. Coal is classified based on its carbon and volatile matter content into peat, lignite, sub-bituminous, bituminous and anthracite. Coal analysis determines the mass percentages of components through proximate analysis of fixed carbon, volatile matter, moisture and ash and ultimate analysis of carbon, hydrogen, oxygen, nitrogen, sulfur and minerals. Combustion equipment for burning coal includes fuel bed furnaces, pulverized coal furnaces, cyclone furnaces and fluidized bed furnaces. Pulverized coal furnaces have become common in utility stations due to their efficiency.