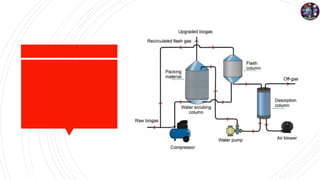

Bio-CNG, or bio-compressed natural gas, is a sustainable fuel created from organic waste through biomethane production, offering environmental benefits by reducing greenhouse gas emissions. The production involves biogas generation from organic materials, followed by purification processes to create high-purity biomethane suitable for various applications. Challenges include feedstock availability, infrastructure development, and market acceptance for broader adoption.