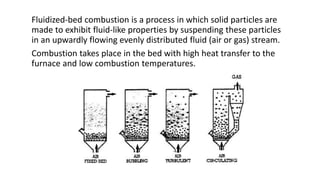

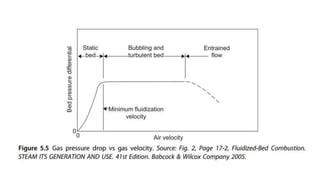

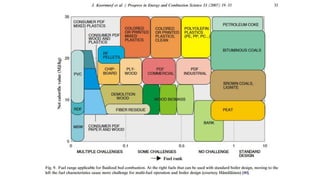

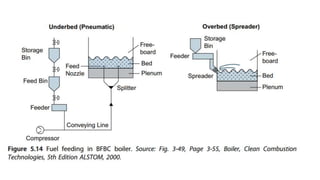

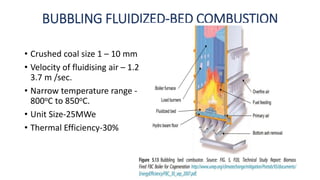

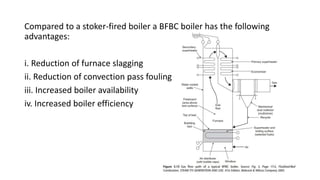

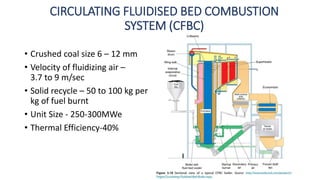

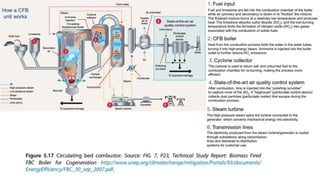

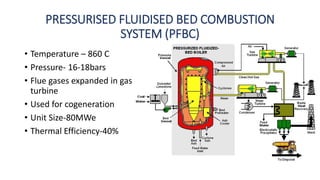

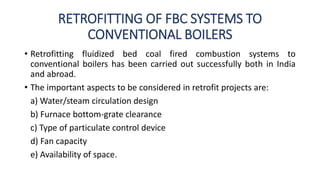

The document describes fluidized-bed combustion (FBC) technology, introduced in the 1920s and used for various applications including waste incineration and coal combustion. It details the types of FBC systems (atmospheric and pressurized), their advantages such as high efficiency and flexibility, and disadvantages including issues with fluidization and wear of parts. The conclusion emphasizes the need for further research to enhance FBC technology for cleaner energy production.