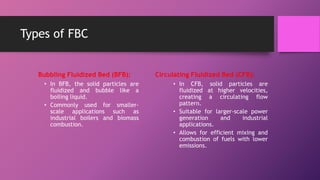

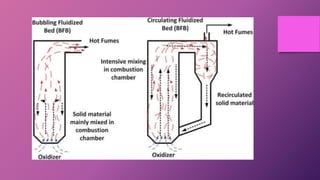

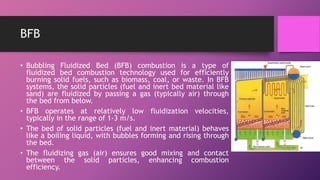

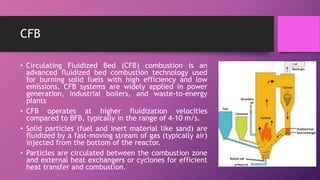

The document discusses pulverized fuel combustion and fluidized bed combustion (FBC), detailing their processes, advantages, and challenges. Pulverized fuel combustion involves finely grinding solid fuels like coal, resulting in high efficiency and low emissions, while FBC utilizes a fluidized bed to enhance combustion and reduce pollutants. Two types of FBC, bubbling fluidized bed (BFB) and circulating fluidized bed (CFB), are described, highlighting their respective applications and efficiencies in burning various solid fuels.