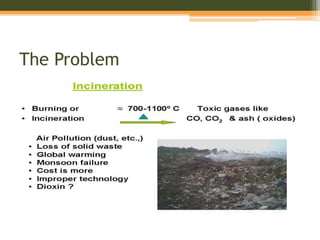

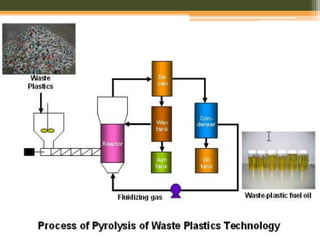

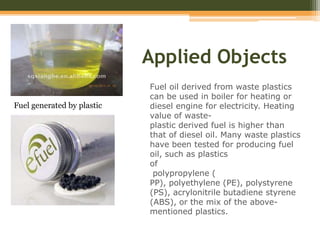

Waste to fuel technologies convert waste into energy sources like fuel. Common methods include incineration which burns waste to create steam and generate electricity, though it risks polluting air. Alternative technologies like pyrolysis heat waste in low-oxygen environments to produce synthetic fuels without combustion. Two students developed a pyrolysis process that cracks plastic molecules at high temperatures and pressures using a catalyst to produce crude oil, gasoline, diesel and kerosene. Their process was certified after analysis showed it converted plastic waste into 80% hydrocarbon oil fuel. Waste to fuel technologies address waste and energy issues while some produce cleaner fuels than incineration.

![WtE Plants around the world

• Lee County Solid Waste Resource

Recovery Facility, Fort Myers, Florida,

USA (1994)[29]

• Montgomery County Resource

Recovery Facility in Dickerson,

Maryland, USA (1995)

• Spittelau (1971), and Flötzersteig

(1963), Vienna, Austria (Wien

Energie)

• SYSAV in Malmö (2003 and 2008),

Sweden (Flash presentation)

• Algonquin Power, Brampton, Ontario,

Canada[30]

• Teesside EfW

plant near Middlesbrough, North East

England (1998)

• Edmonton Incinerator in Greater

London, England (1974)

• Burnaby Waste-to-Energy

Facility, Metro

Vancouver, Canada (1988).](https://image.slidesharecdn.com/wastetofueln-140725234944-phpapp02/85/Waste-to-fuel-13-320.jpg)