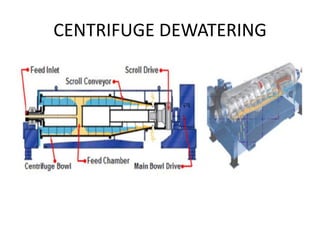

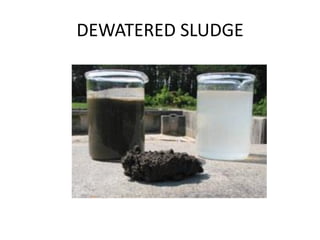

Dewatering is used to remove water from digested sludge before disposal. Common dewatering methods include sludge drying beds, centrifuges, and belt filter presses. Sludge drying beds are the simplest method but require more space. Centrifuges use high rotational force to separate solids from liquids. Key factors that impact centrifuge dewatering performance are rotational speed, differential speed between the bowl and conveyor, solids loading rate, and use of polymers to improve dewaterability. Typical centrifuge dewatering results in a 28-33% dry solids content in the dewatered sludge from an initial 2-4% solids content.