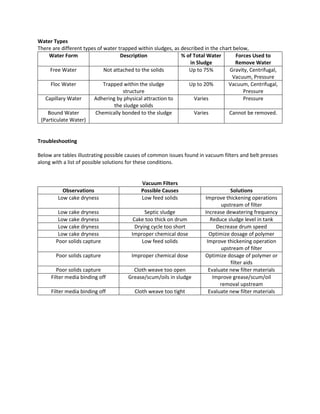

This technical bulletin discusses the various aspects of wastewater sludge dewatering, focusing on its types, regulatory concerns, and disposal methods. It outlines different dewatering technologies such as belt presses, vacuum filters, and centrifuges, detailing their operational mechanisms, efficiencies, and the role of polymers in enhancing the separation of water from sludge. Additionally, the document provides troubleshooting strategies and calculations for optimizing polymer dosage in sludge treatment processes.