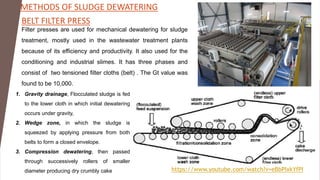

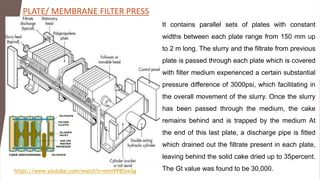

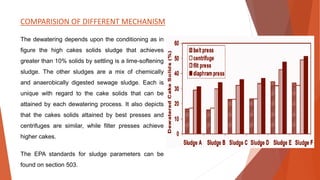

Sludge dewatering is essential in wastewater treatment to reduce sludge volume by increasing solid content from 2%-6% to 12%-35%. Various methods, such as filter presses and centrifuges, effectively separate solids from liquids, each with different efficiencies and applications based on sludge type and environmental conditions. Advancements in technology enhance the process's efficiency, making sludge treatment more environmentally friendly and allowing for the recycling of extracted water.

![SLUDGE

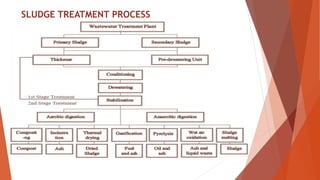

The semi solid slurry obtained as

the by-product from treatment

plants such as waste from coal

washery or suspended solids

from water treatment plants

termed as “SLUDGE”.

If the sludge is organic in origin (major constituents N

and P and energy (C)) is termed as biosolids either

obtained from industrial or municipal treatment plants

[2].

SLUDGE

Secondary Mixed

Activated/

Digested

Physicoche

mical

Mineral

Primary

Types of Sludge

The dumping of raw sludge in

ocean was banned in 1987

under the Helsinki Agreement

Why its need to be treated?](https://image.slidesharecdn.com/en-15minzamumtaz-210126065616/85/Sludge-Dewatering-2-320.jpg)

![REFERENCES

[1] Naem Sadiq, “Karachi sinking in its own sewage,” The Express Turbine, Karachi, Aug. 18, 2018.

[2] “Sludge Dewatering,” Hiller Separation & Process. http://www.hiller-us.com/sludge-

dewatering.php#:~:text=Sludge%20dewatering%20is%20the%20separation,(%22the%20centrate%22).

[3] G. Kiely, Environmental Engineering. McGraw- Hill, 1998.

[4] G. Chen, P. L. Yue, and A. S. Mujumdar, “Sludge dewatering and drying,” Drying Technology, vol. 20, no.

4–5, pp. 883–916, 2002, doi: 10.1081/DRT-120003768.

[5] J. T. Novak, “Dewatering of sewage sludge,” Drying Technology, vol. 24, no. 10, pp. 1257–1262, 2006,

doi: 10.1080/07373930600840419.

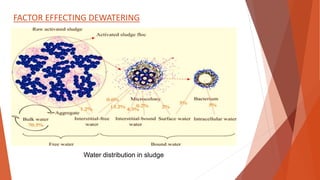

[6] “Water distribution in sludge.” https://www.sciencedirect.com/science/article/abs/pii/S0964830516303924.

[7] R. J. Wakeman, “Separation technologies for sludge dewatering,” Journal of Hazardous Materials, vol.

144, no. 3, pp. 614–619, Jun. 2007, doi: 10.1016/j.jhazmat.2007.01.084.

[8] https://steemit.com/steemstem/@akeelsingh/equipment-of-filtration-part-2, “Filter press.” .

[9] http://www.chinafilterpress.net/application/sludge-dewatering-centrifuge.html, “Centrifuge.”

http://www.chinafilterpress.net/application/sludge-dewatering-centrifuge.html (accessed Sep. 25, 2020).

[10] O. Franceschini, “Dewatering of sludge by freezing.” 2010.

[11] Rohit Bhagwat (Ecosan Services Foundation (ESF)), “Sludge drying beds.”

[12] “Sludge Lagoons,” Eurocode Standards, Aug. 01, 2019.](https://image.slidesharecdn.com/en-15minzamumtaz-210126065616/85/Sludge-Dewatering-18-320.jpg)