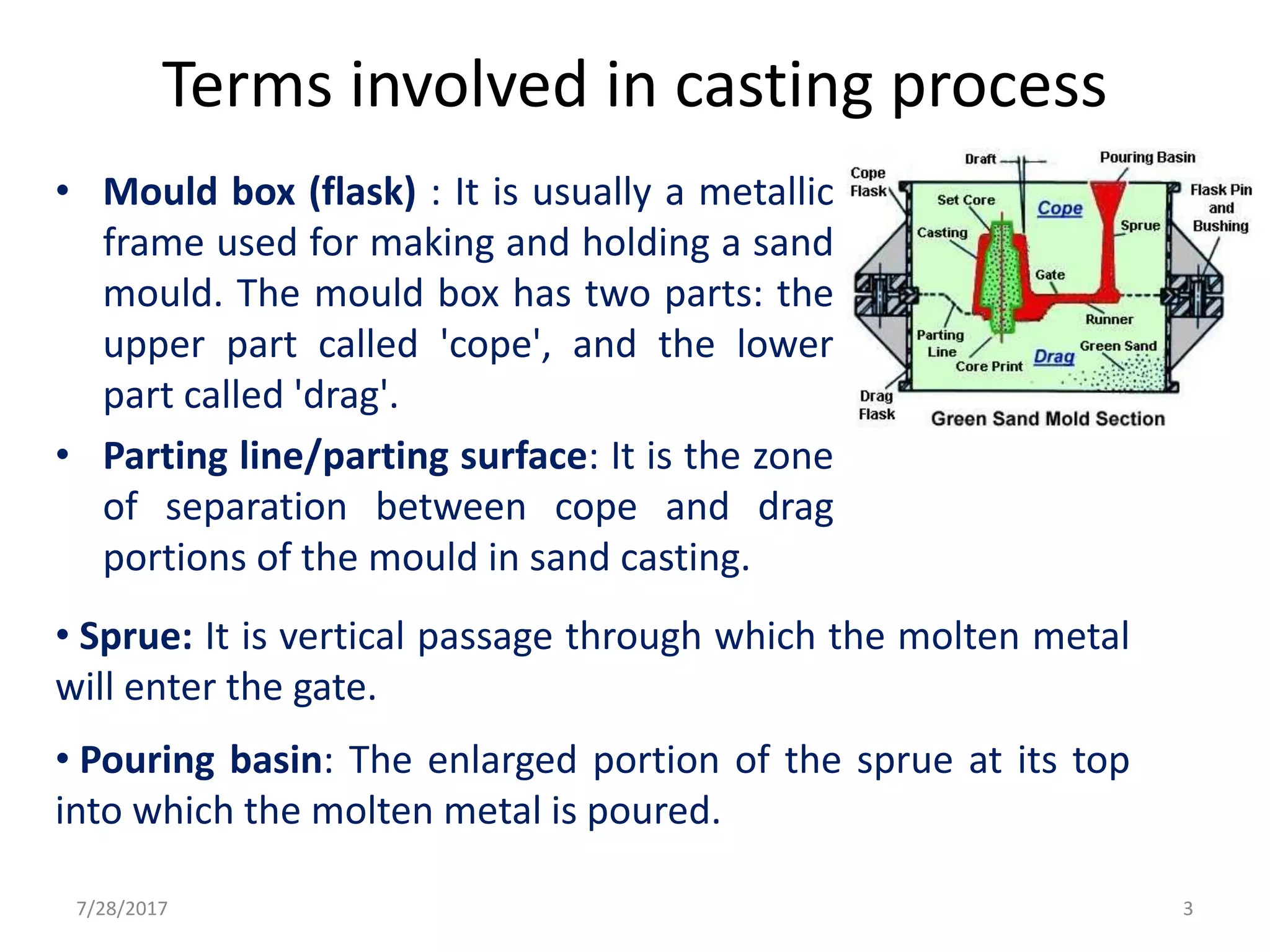

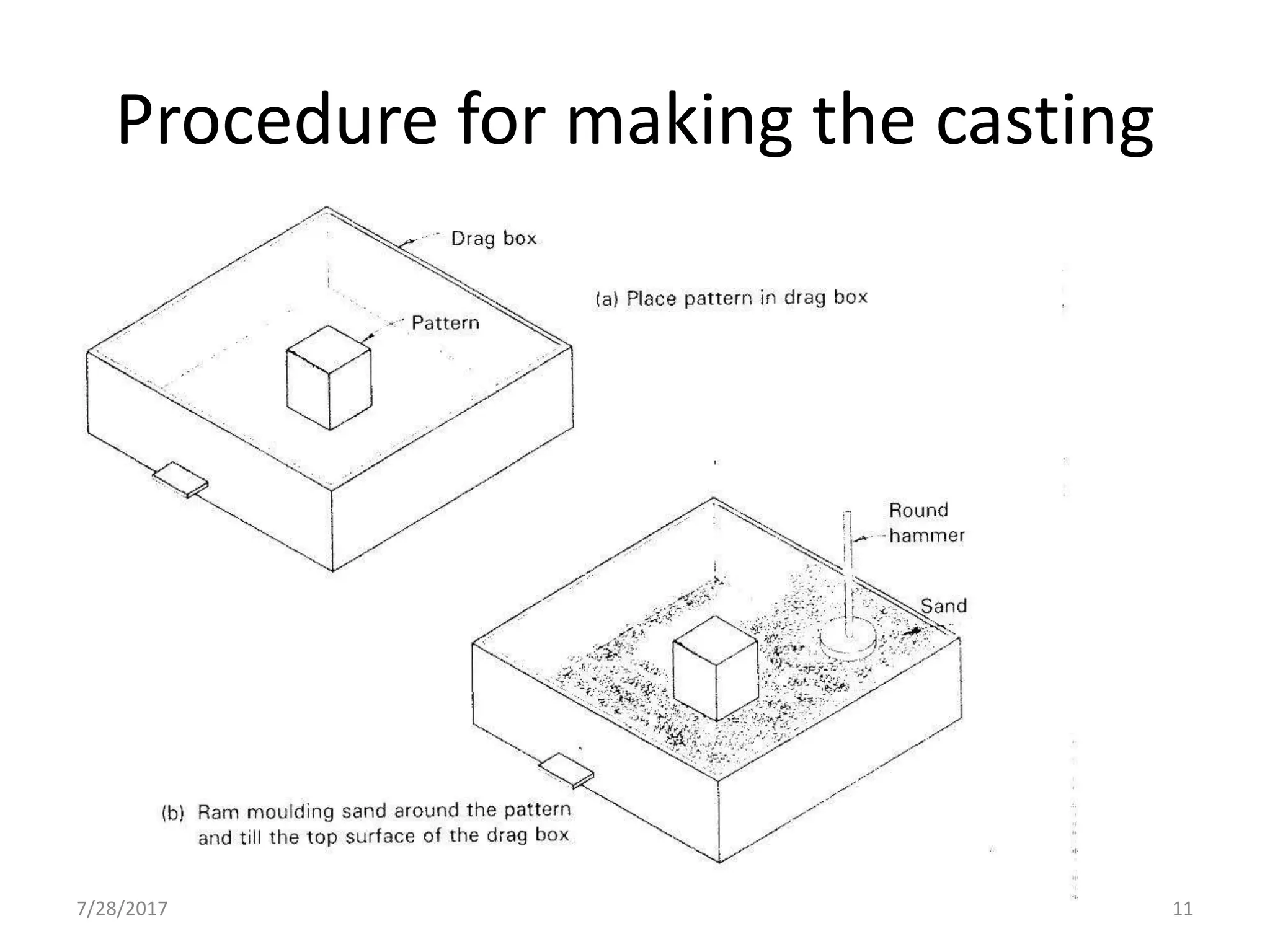

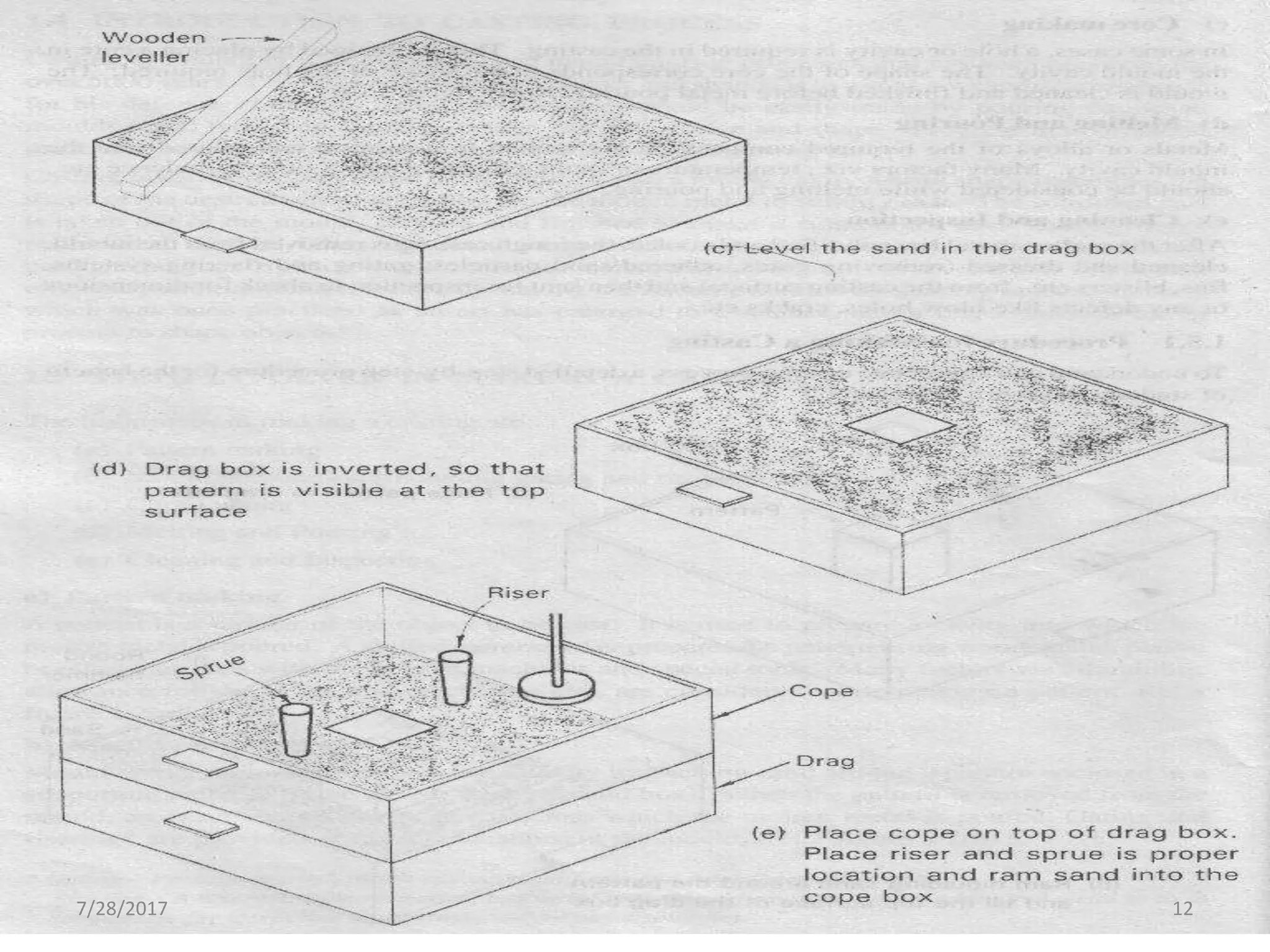

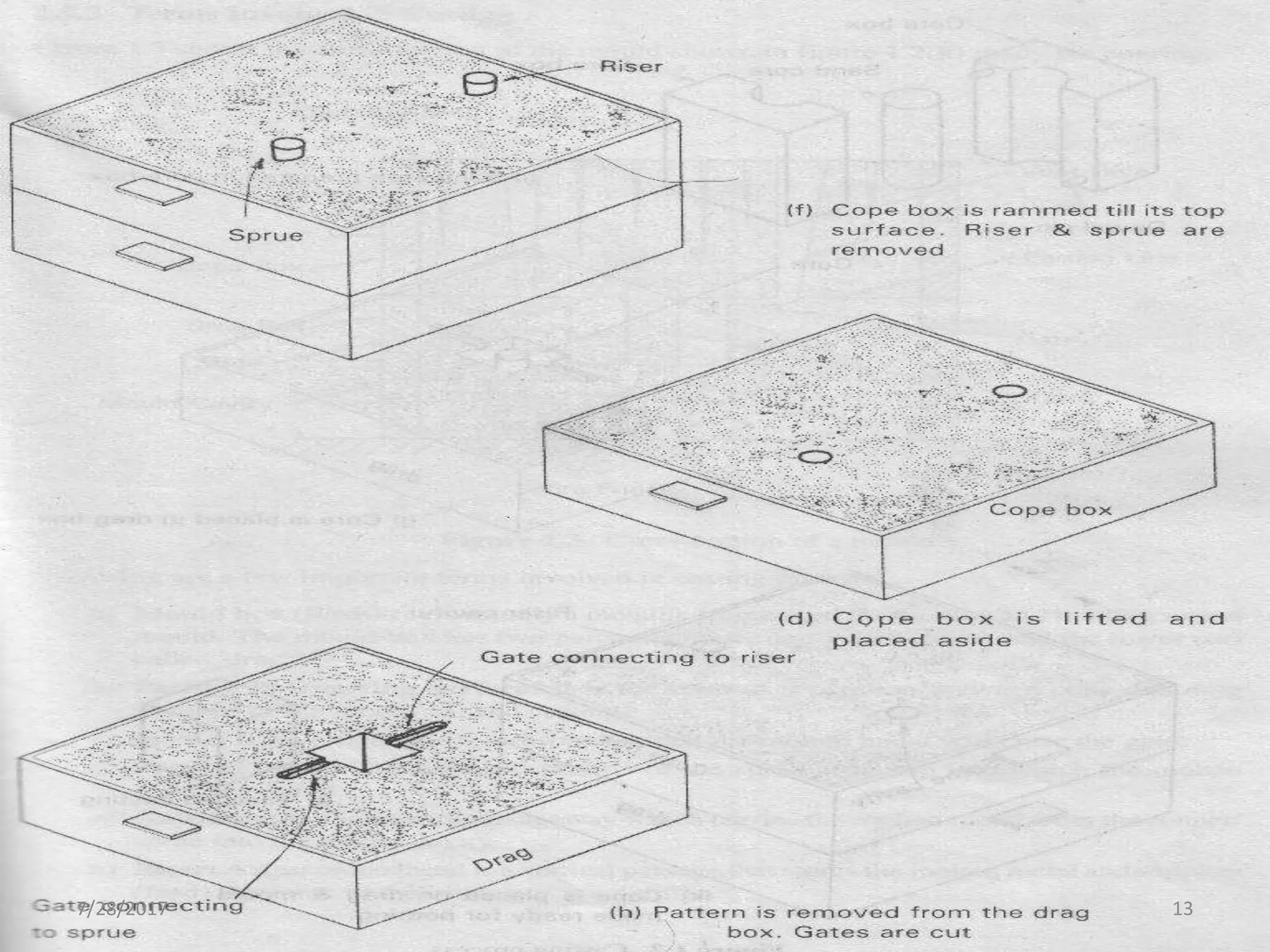

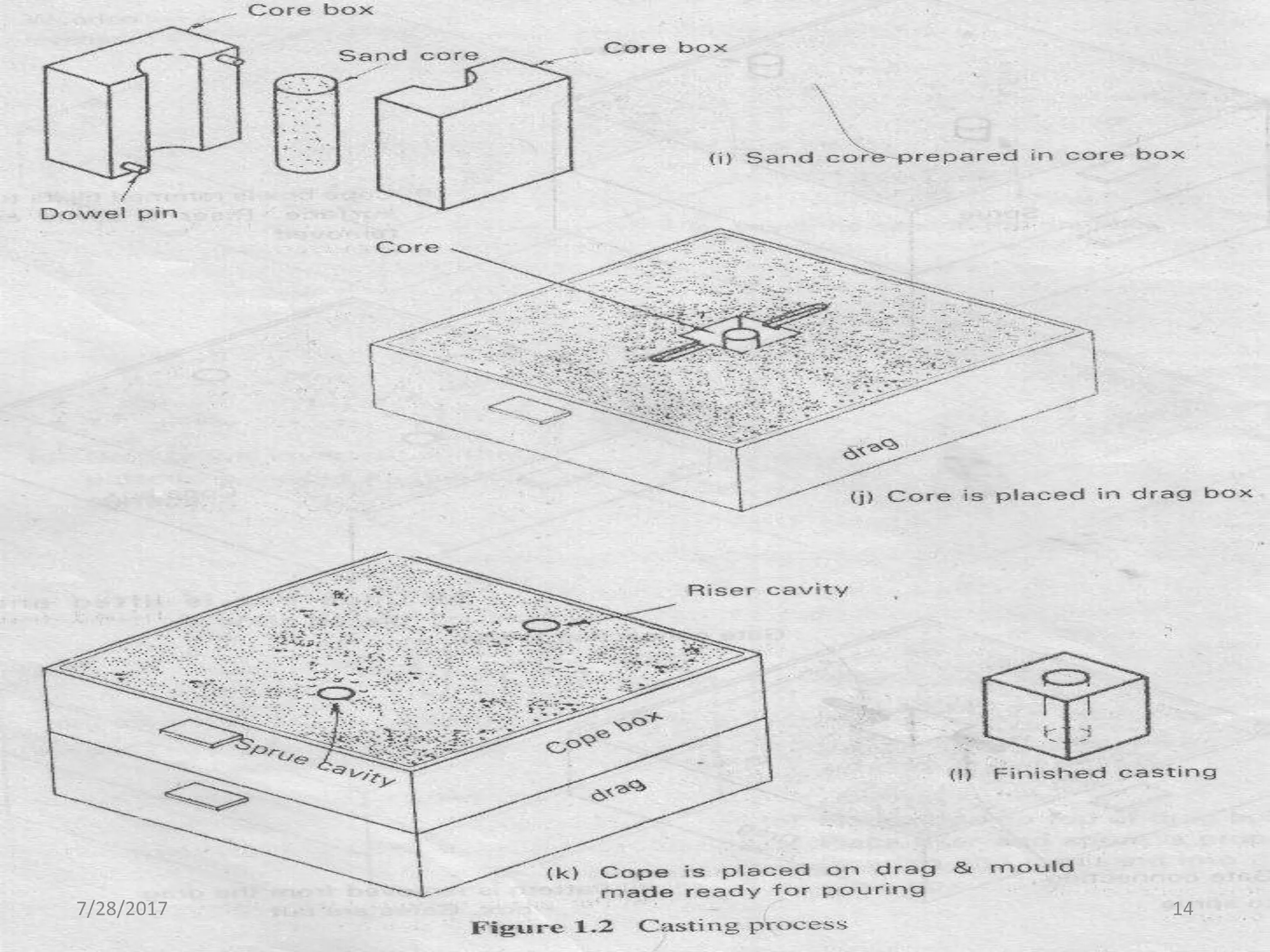

The document describes the casting process and its key terms. It discusses the main steps: pattern making, mould preparation including gating and risering, core making, melting and pouring, and cleaning and inspection. It provides details on each step and describes how a mould is made by packing sand around a pattern. Common components produced by casting are also listed, such as automobile and aircraft parts. Advantages include the ability to make complex shapes easily and economically, while limitations include potential defects and inferior properties compared to other processes.