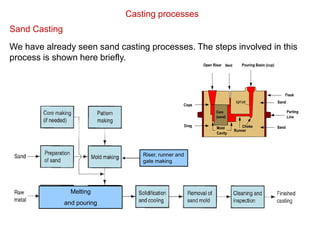

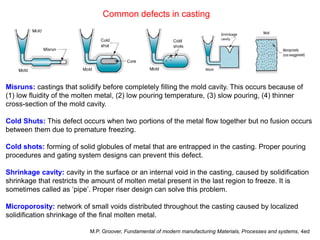

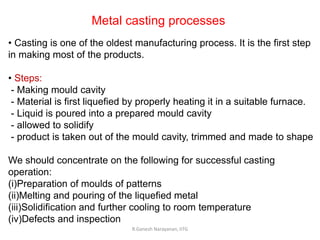

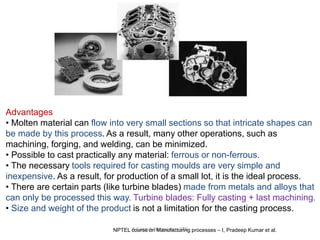

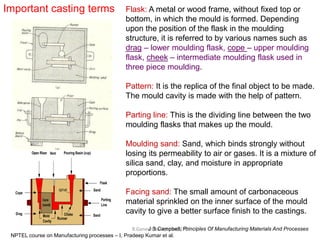

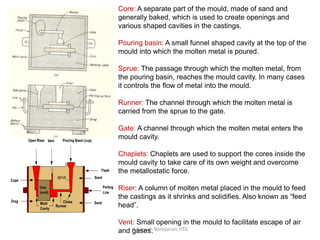

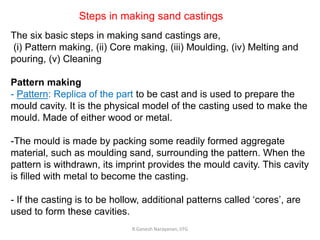

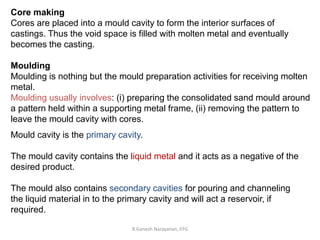

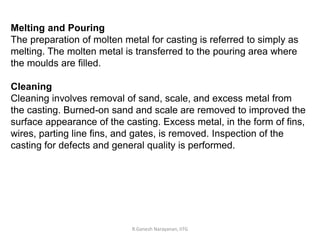

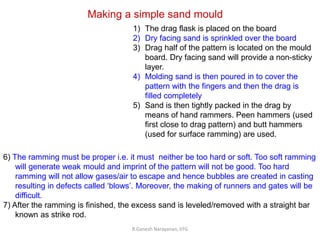

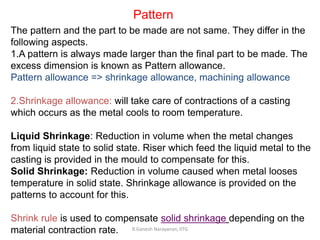

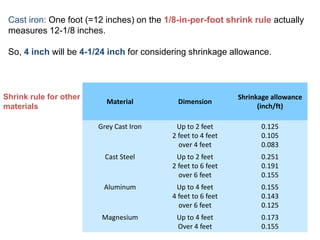

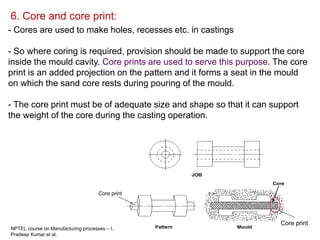

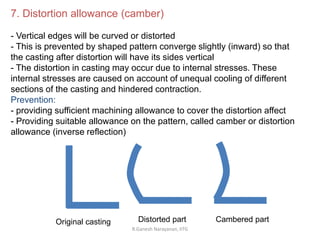

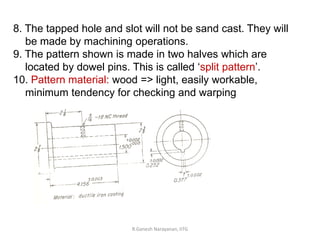

This document provides information on the manufacturing process of metal casting. It discusses the key steps in metal casting which include mould preparation, pouring molten metal, solidification, and inspection for defects. Moulds are prepared using sand and patterns to form cavities. Molten metal is poured into the mould and allowed to solidify to form the final casting. Proper mould design and avoiding defects are important for successful casting. Metal casting allows for intricate shapes but has limitations in dimensional accuracy and surface finish compared to other processes.

![R.Ganesh Narayanan, IITG

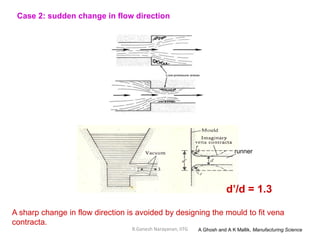

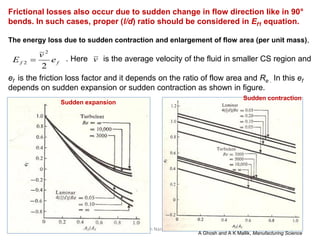

The energy balance eqn. between points 1 and 3, after accounting for sudden

contraction loss at 2 is given by,

By having P1 = P3, and using equations and , we get

If the sprue has got a bend or fitting,

tD ghCv 23 2/1

)4

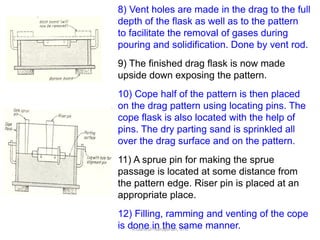

1

(

d

l

feC fD

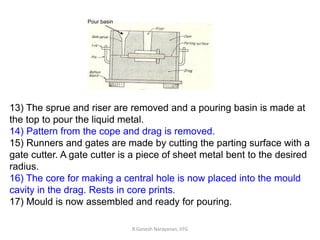

where

2/1

]})([4

1

{

eqfD

D

L

d

l

feC

Here l and d are length and diameter of channel (like sprue), (L/D) eq is for the bend.

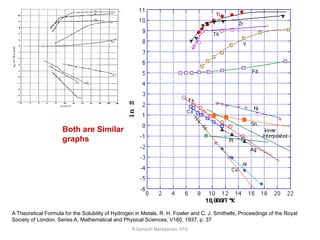

A Ghosh and A K Mallik, Manufacturing Science

21

2

331

2

0 EfEf

vp

gh

p

m

t

m

d

vfl

Ef

2

4 2

1 ff e

v

E

2

2

2

CD = discharge coefficient

3

2

33

31

2

11

1

22

F

g

v

g

p

hF

g

v

g

p

h

](https://image.slidesharecdn.com/castingprocess-150721064844-lva1-app6891/85/Casting-process-94-320.jpg)

, but practically any

shaped contour can be used.

2

0

2

)

)(2

)]([

()(

f

fpmm

s

k

cL

where

A

V

t

Chvorinov’s rule](https://image.slidesharecdn.com/castingprocess-150721064844-lva1-app6891/85/Casting-process-107-320.jpg)

(

)(

0

0

A Ghosh and A K Mallik, Manufacturing Science](https://image.slidesharecdn.com/castingprocess-150721064844-lva1-app6891/85/Casting-process-110-320.jpg)