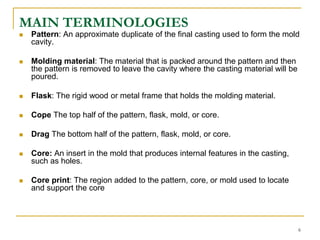

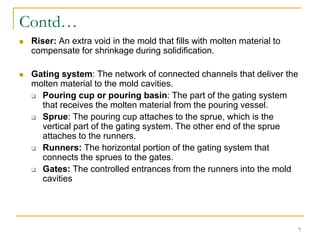

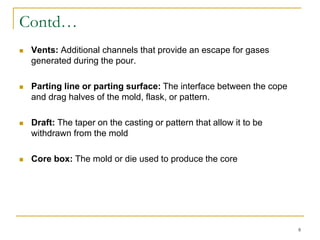

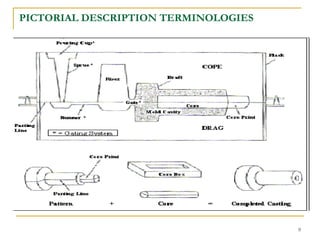

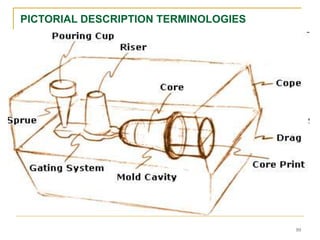

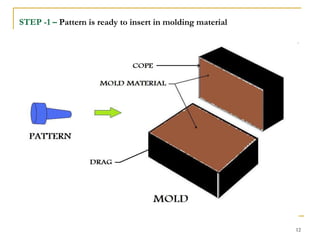

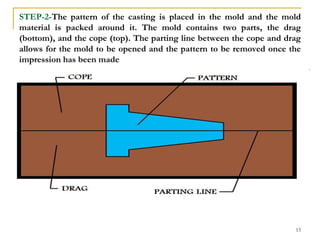

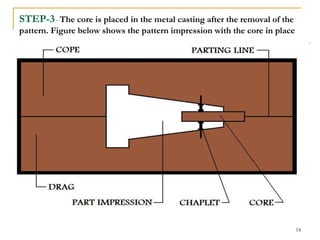

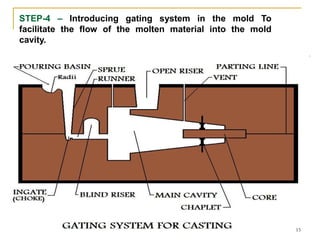

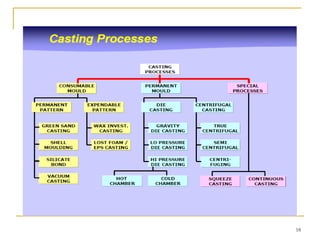

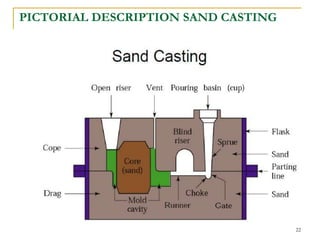

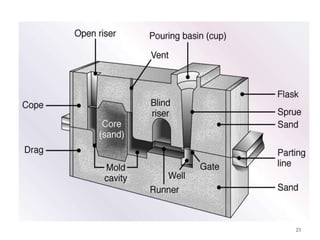

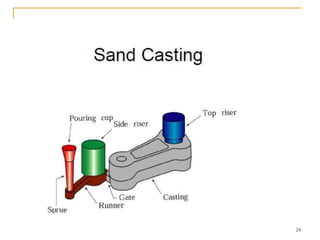

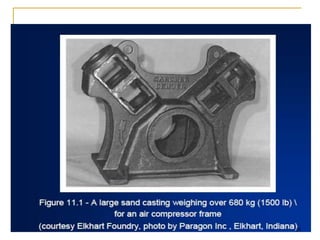

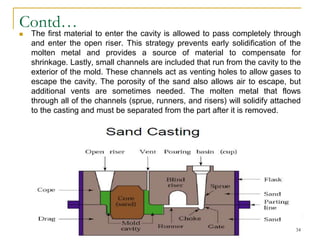

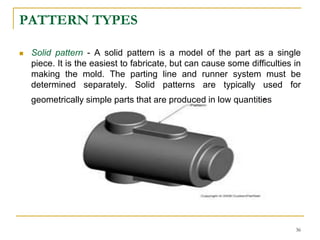

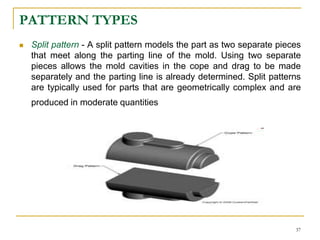

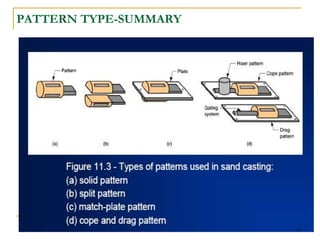

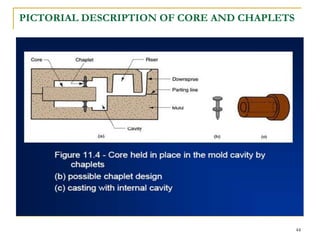

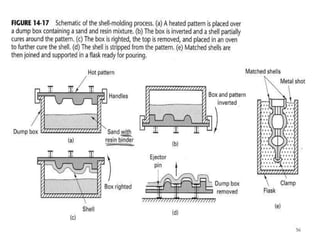

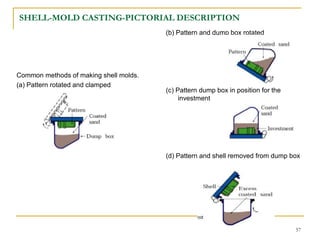

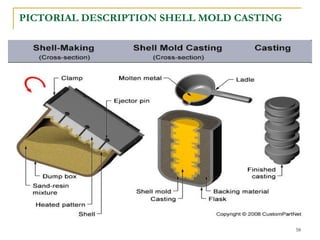

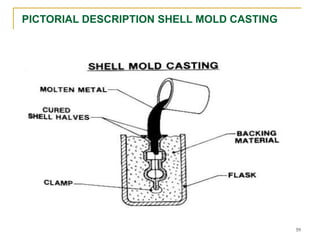

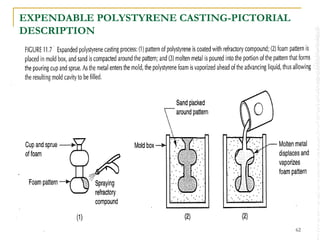

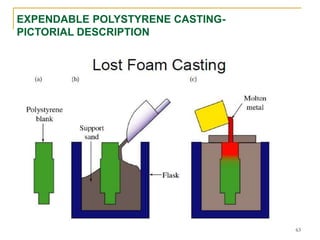

The document describes the metal casting process. It defines casting as pouring liquid metal into a mold cavity to create a solidified part. The mold is made by packing sand around a pattern, which is then removed, leaving a cavity in the shape of the desired part. The mold contains cores and a gating system to deliver molten metal to the cavity. After solidification, the part is broken out of the mold. Sand casting is described as the most common casting method, involving a sand mold with clay binder that is packed around a disposable pattern.