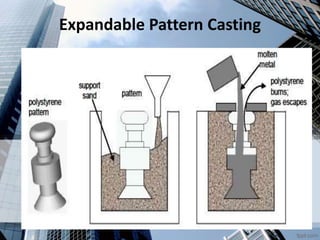

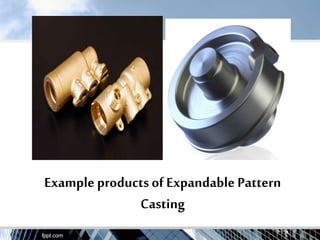

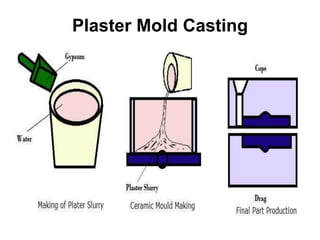

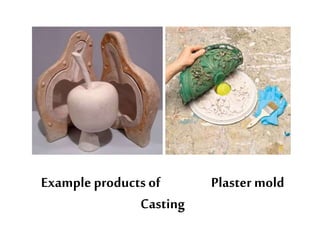

Expandable pattern casting and plaster mold casting are two types of expendable mold casting processes. Expandable pattern casting uses an expandable polystyrene pattern that is coated, embedded in sand in a flask, and then vaporized when molten metal is poured, leaving an exact replica of the pattern. Plaster mold casting similarly uses a plaster mold instead of sand and is best for smaller, non-ferrous metal castings due to temperature limitations of plaster. Both methods can produce complex, close-tolerance castings with minimal finishing required.