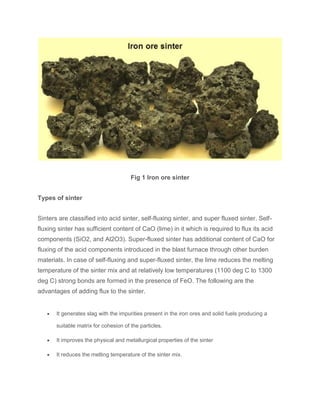

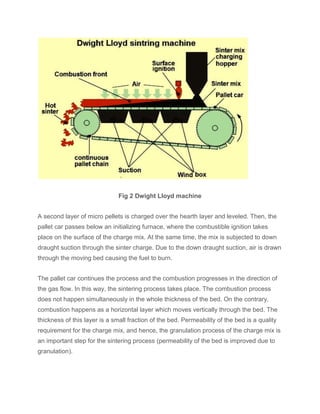

The document summarizes the sintering process used in iron making. Sintering involves heating a mixture of iron ore fines, return fines, and fluxes to partially melt the materials and form porous agglomerates called sinter. This sinter product is the main burden material charged to blast furnaces. The key steps are granulation of the raw materials, formation of a sinter bed on a moving grate, combustion through the bed which agglomerates the materials, and screening of the final sinter product into sizes suitable for the blast furnace burden. Proper control of variables like feed moisture and burn-through point are important for stabilizing the process.