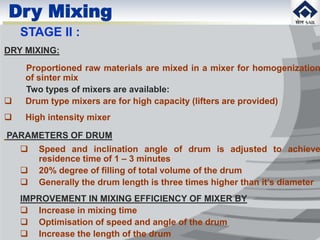

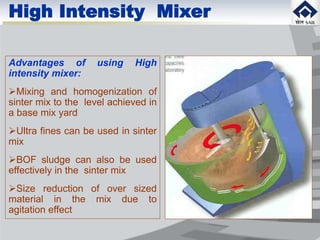

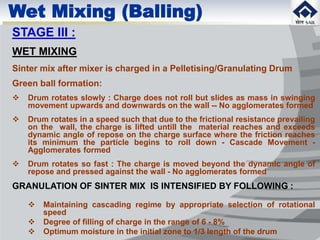

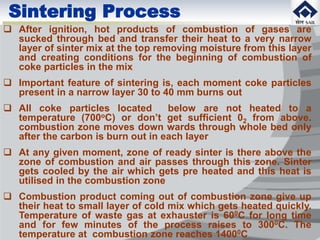

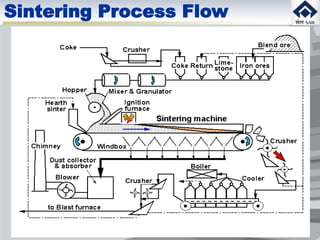

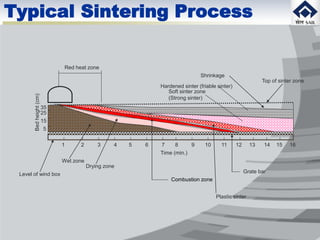

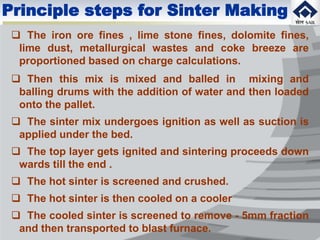

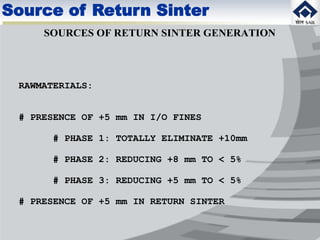

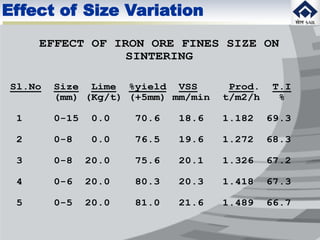

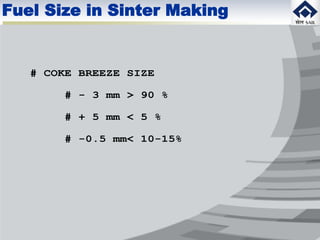

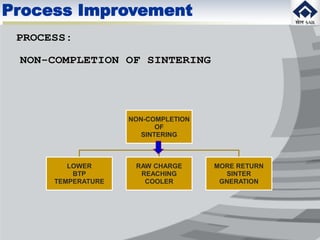

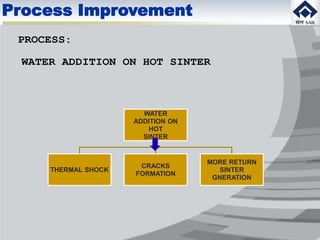

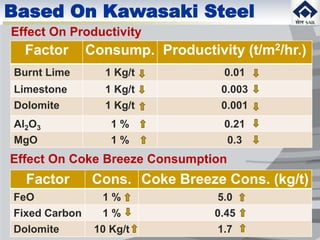

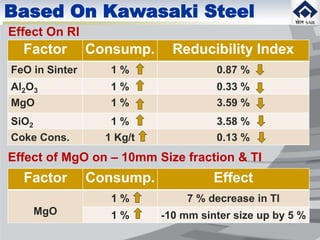

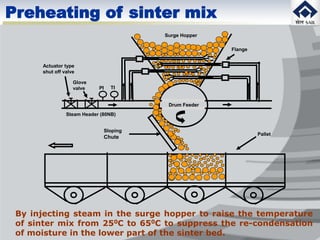

The document discusses sinter making technology used in iron ore mining. It describes how iron ore fines generated during mining cannot be directly charged in blast furnaces due to size restrictions. Sintering is used to agglomerate the fines into a porous mass that meets size requirements. The key steps in sinter making include: 1) raw material preparation through crushing, mixing and granulation to produce a homogeneous mixture, 2) ignition of the mixture on a traveling grate where combustion of fuel preheats and agglomerates the fines into sinter.