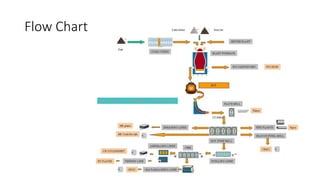

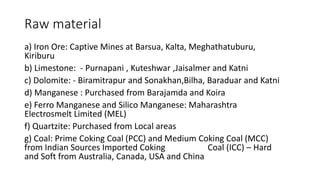

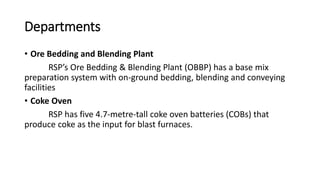

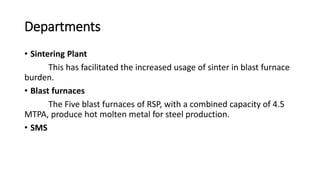

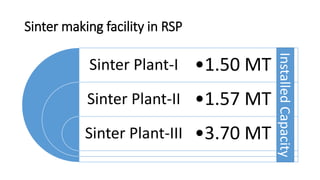

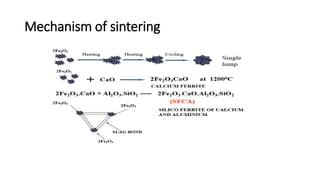

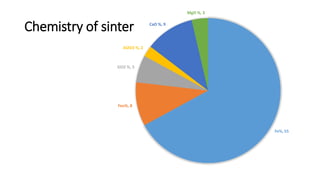

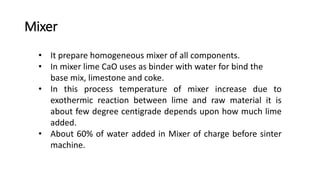

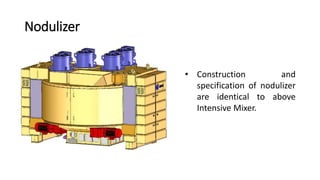

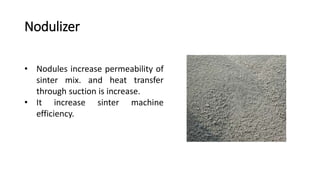

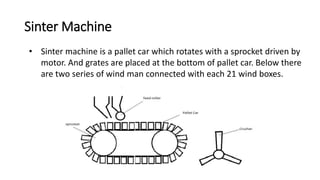

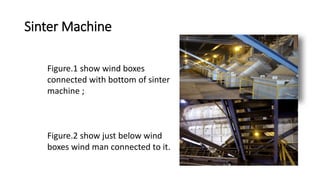

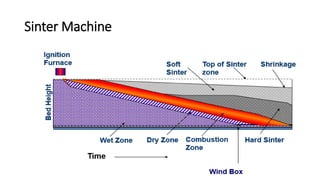

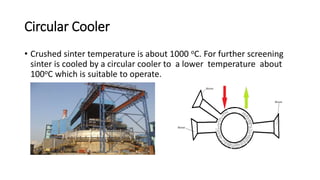

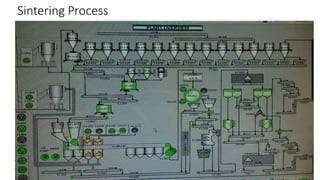

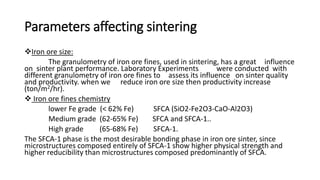

The document discusses the sintering process used at the Rourkela Steel Plant in India. It describes how iron ore fines, limestone, dolomite and other raw materials are blended and formed into nodules. These nodules are then processed through a sintering machine, where combustion of coke forms sintered agglomerates. The sinter is cooled, crushed, and screened before use as a raw material input for blast furnaces. Key aspects of the sinter plant like the mixer, nodulizer, sinter machine, cooler and screens are explained. Parameters that affect sintering quality like raw material chemistry and size, moisture content, and suction pressure are also summarized.