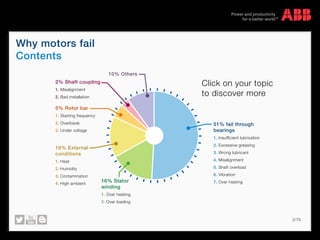

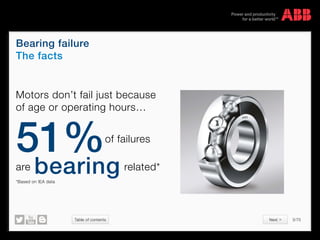

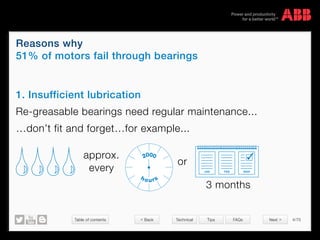

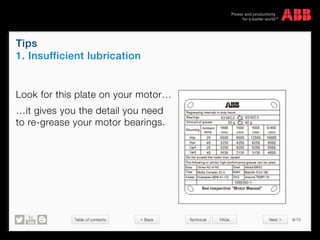

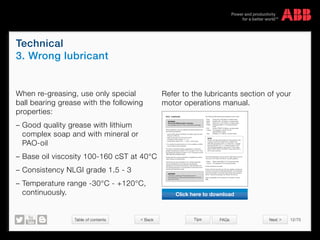

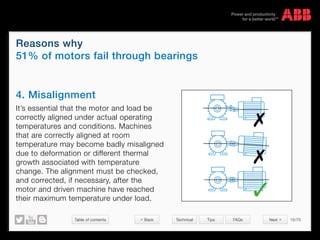

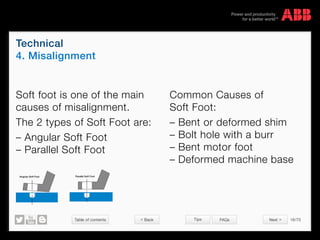

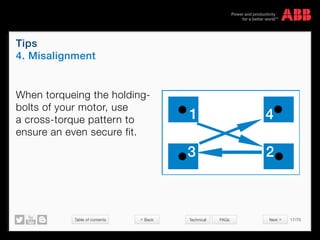

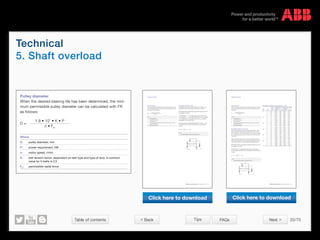

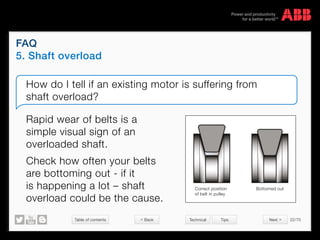

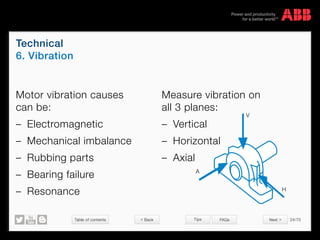

This document provides information on reasons why motors commonly fail, focusing on failures related to bearings. It states that 51% of motor failures are caused by bearings, and describes several common causes: insufficient lubrication, excessive greasing, wrong lubricant, misalignment, and shaft overload. It includes technical details, tips, and frequently asked questions about each cause to help users understand and prevent bearing failures in motors.