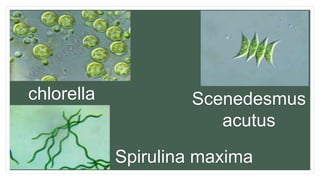

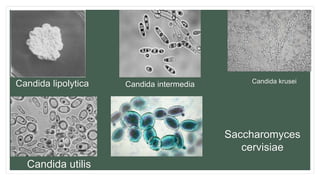

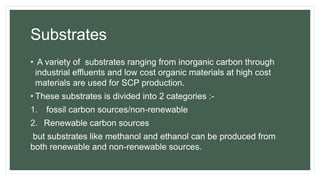

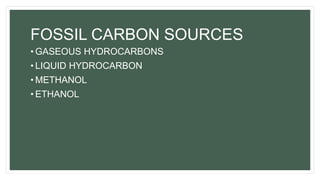

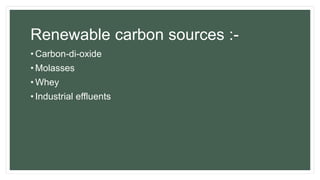

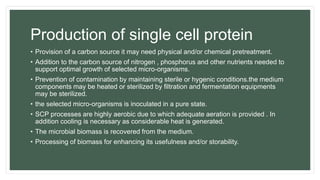

Single cell protein (SCP) can be produced from microorganisms like algae, fungi, yeast and bacteria. SCP has the potential to relieve protein deficiency by being used directly as a human food supplement or indirectly by partially replacing soybean meal and fish proteins in animal feed. Microorganisms used for SCP production must meet certain criteria like being non-pathogenic, nutritious, easily produced at large scale, toxin-free, and fast-growing. Different microorganisms have different advantages and disadvantages for SCP production. Nucleic acid levels must be reduced for human consumption. SCP is produced through fermentation using various carbon sources and nutrients, followed by biomass recovery, processing, and evaluation to