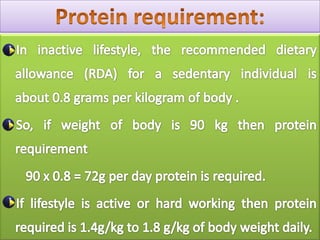

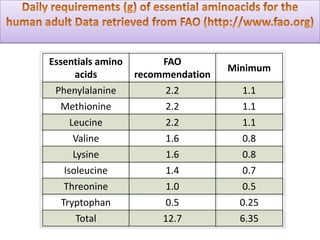

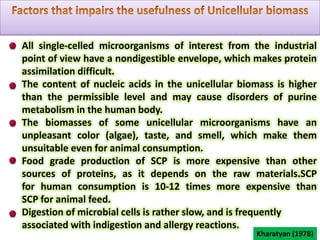

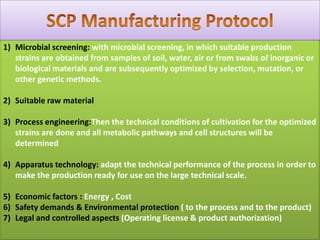

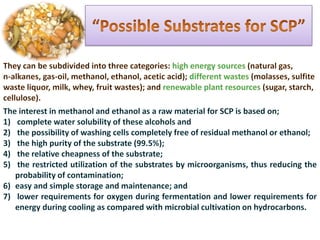

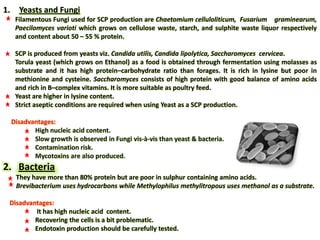

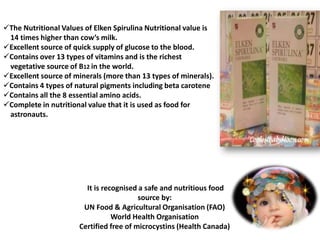

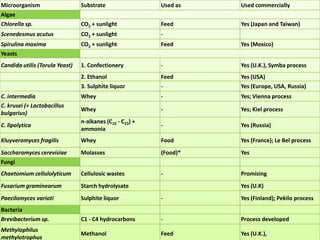

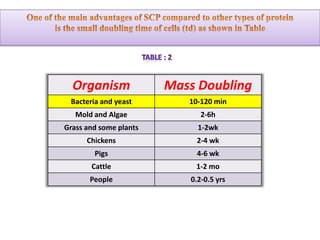

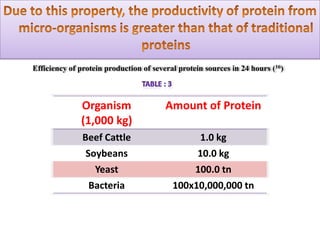

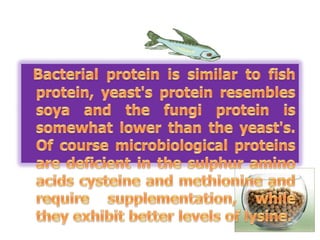

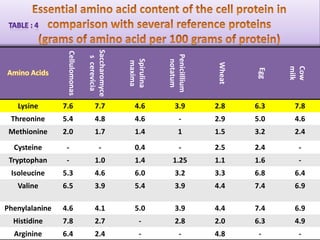

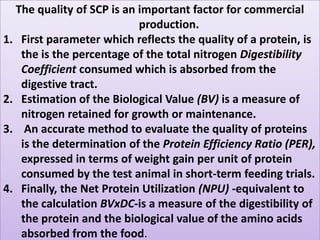

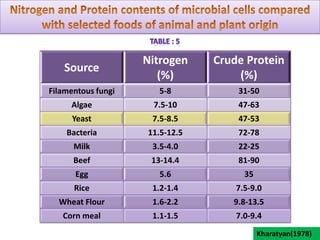

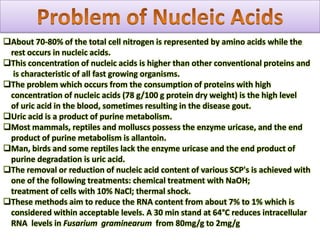

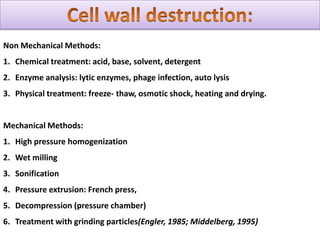

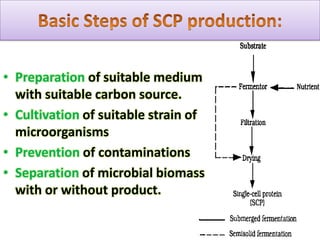

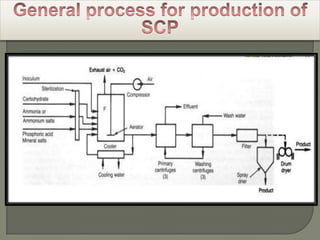

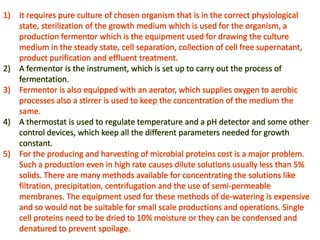

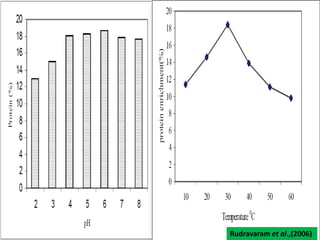

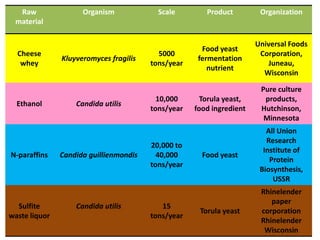

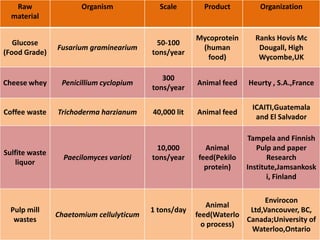

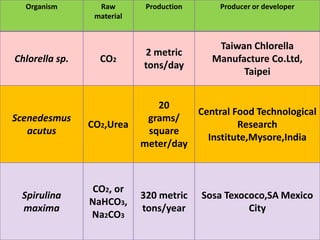

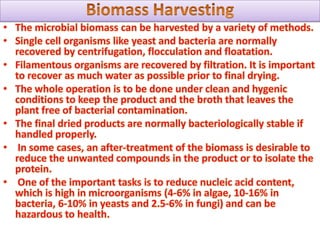

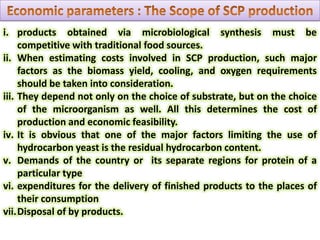

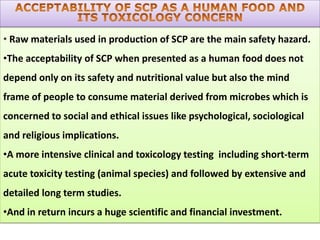

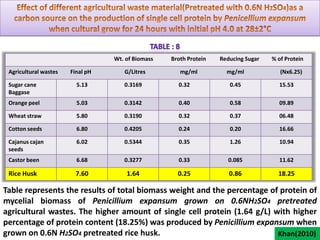

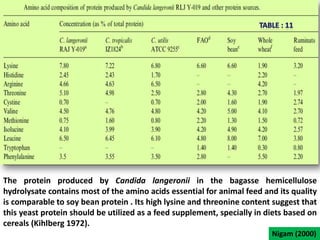

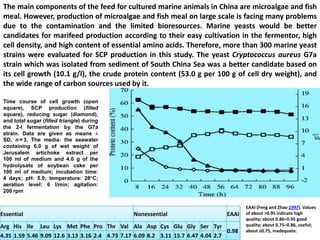

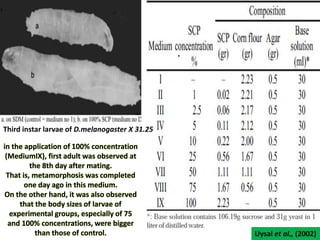

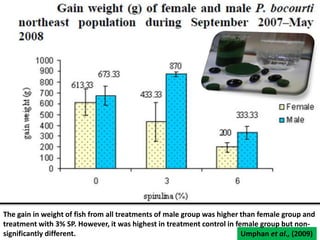

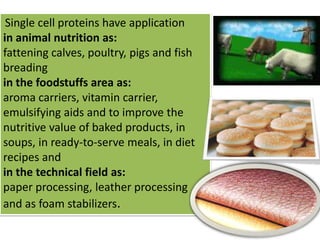

This document discusses single cell protein (SCP) as an alternative protein source. It provides information on the protein content and amino acid composition of various microorganisms used for SCP production, including yeasts, fungi, bacteria and algae. Key microorganisms discussed are spirulina, chlorella, and various yeasts and fungal species. The document also covers the history of SCP, advantages over conventional proteins, factors impacting usefulness for human consumption, production methods, and substrates used.