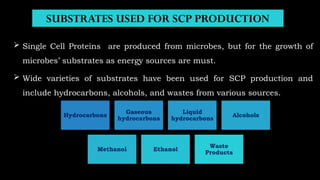

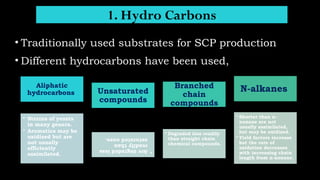

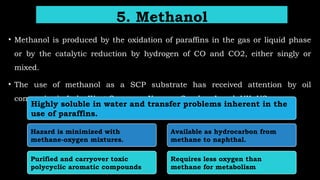

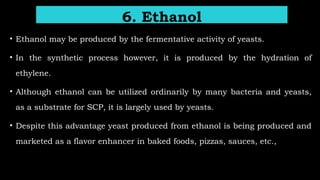

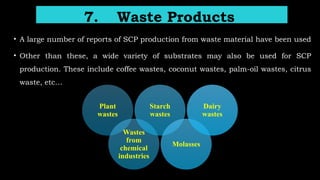

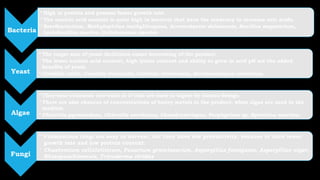

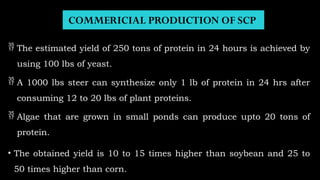

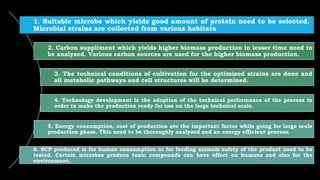

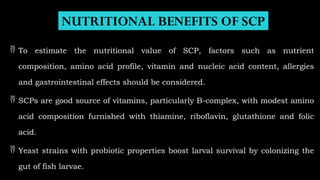

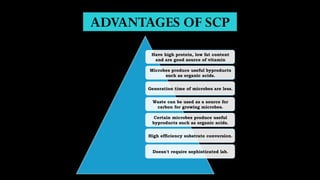

Single cell proteins (SCP) are derived from microorganisms like algae, yeast, fungi, and bacteria, providing a potential solution to protein malnutrition. SCP production utilizes various substrates including hydrocarbons, alcohols, and waste materials, while considering microbial strains for optimal growth and protein yield. Despite advantages such as high protein content and efficiency, there are concerns regarding gastrointestinal issues and toxic compounds associated with certain microorganisms.