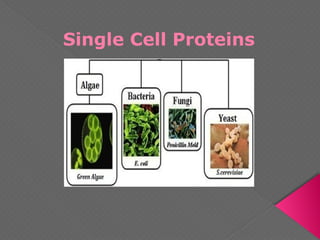

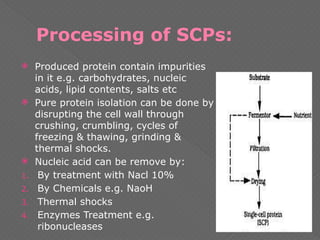

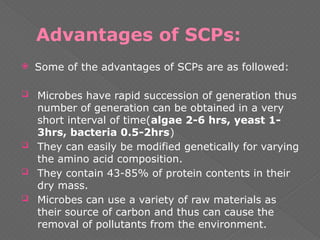

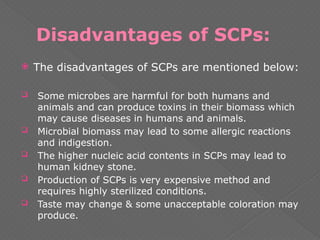

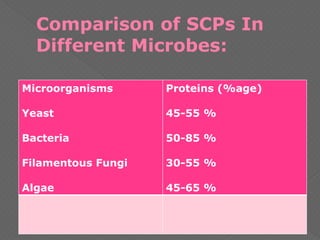

Single cell proteins (SCP) are protein-rich food supplements derived from microorganisms like yeast, algae, fungi, and bacteria, aimed at addressing food shortages due to population growth and energy crises. The production process involves selecting a non-toxic microbe, fermentation, harvesting, and processing to isolate pure protein, while offering advantages such as rapid growth and ecological benefits, alongside disadvantages like toxicity and high production costs. SCPs serve various applications, including food production and animal feed, and their development represents an emerging field in biotechnology with potential improvements through genetic modification.