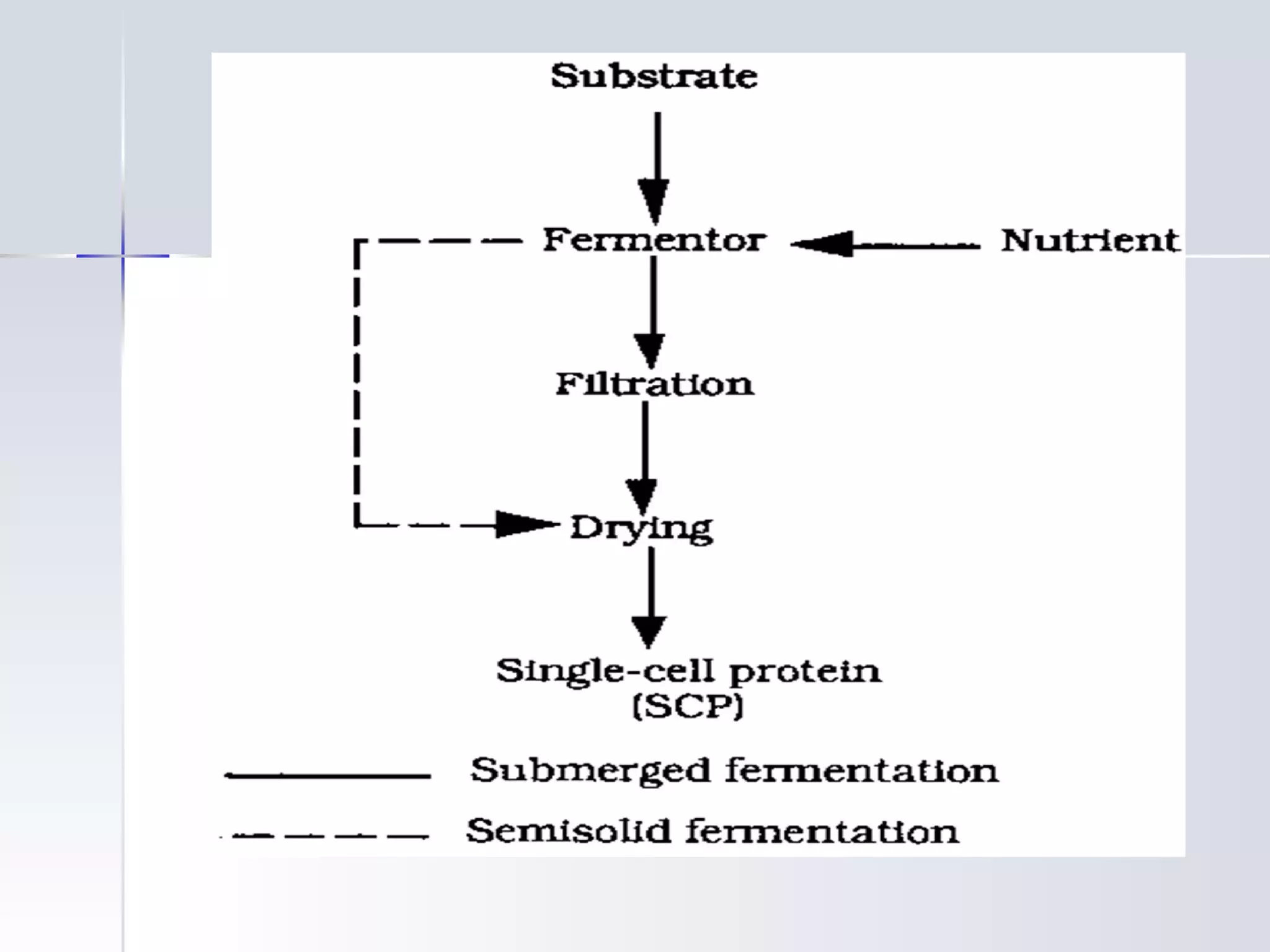

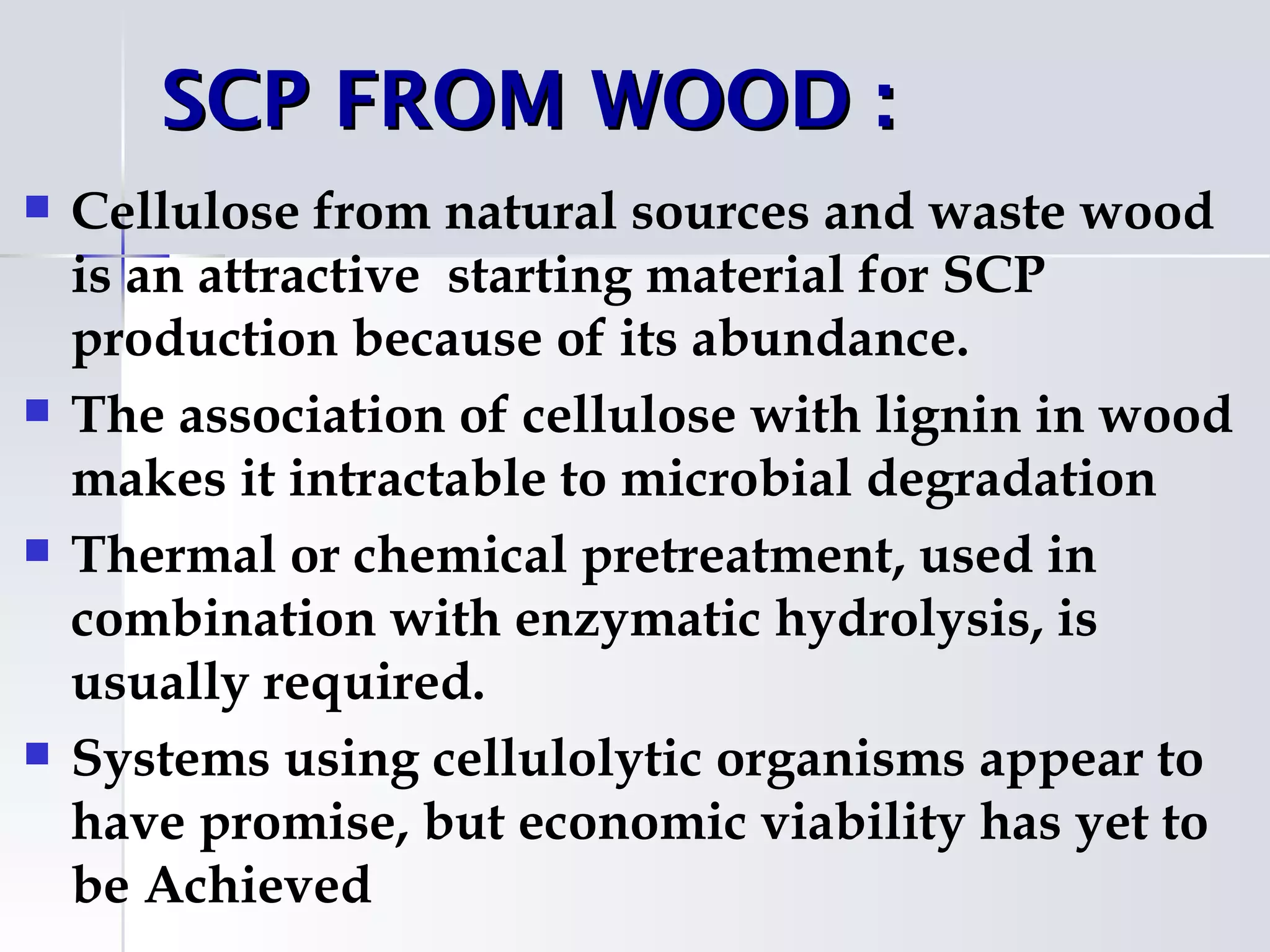

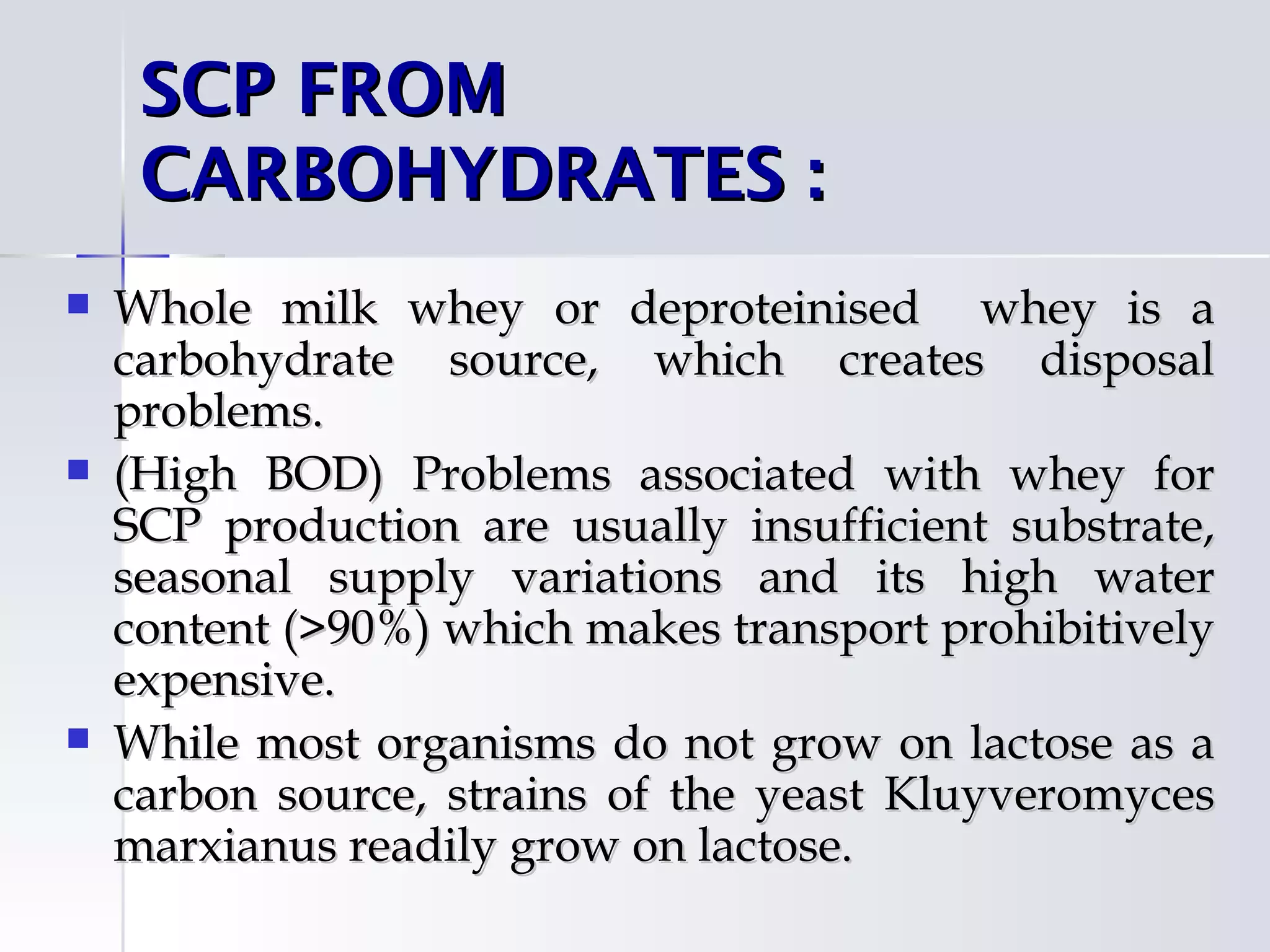

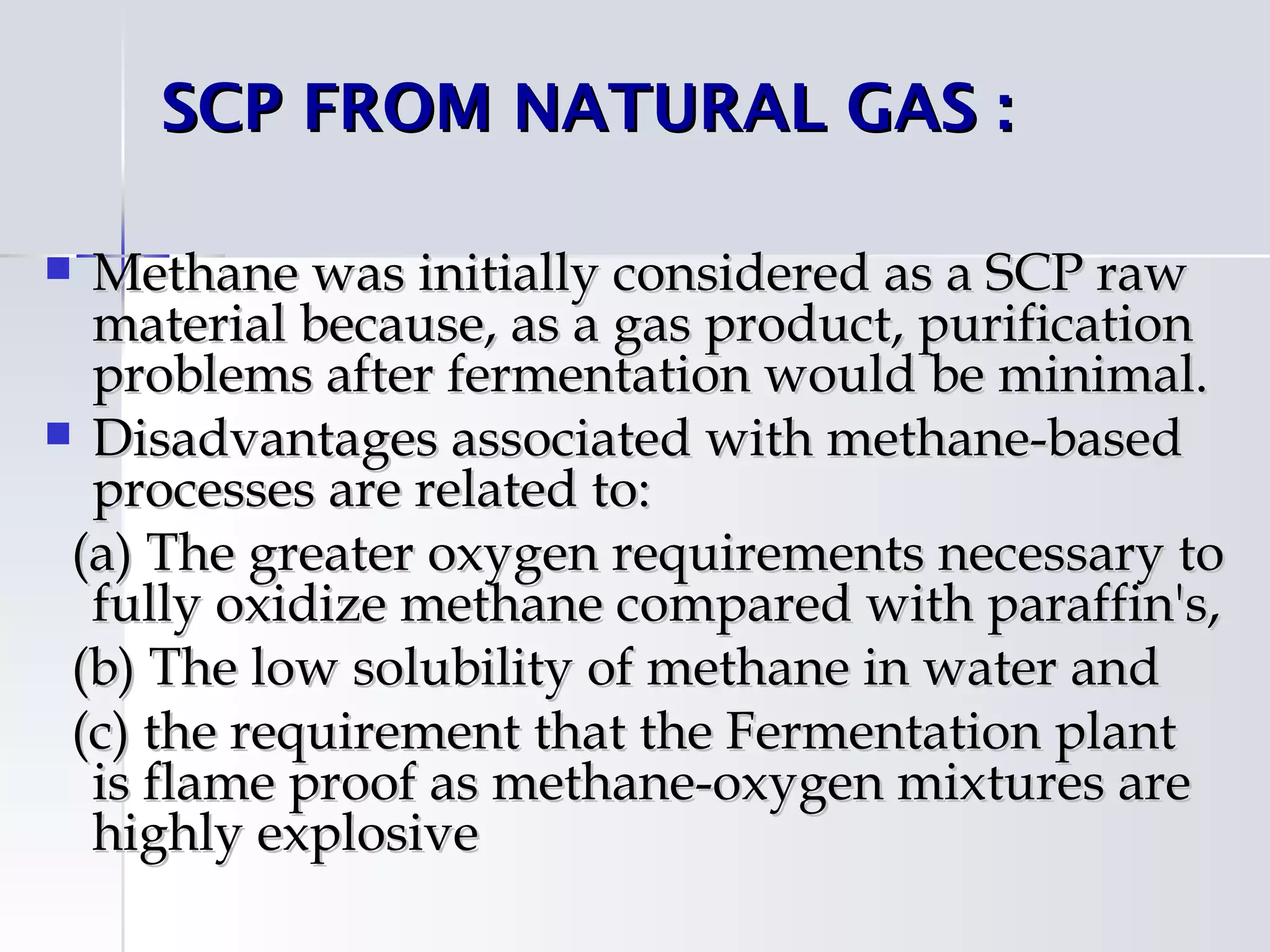

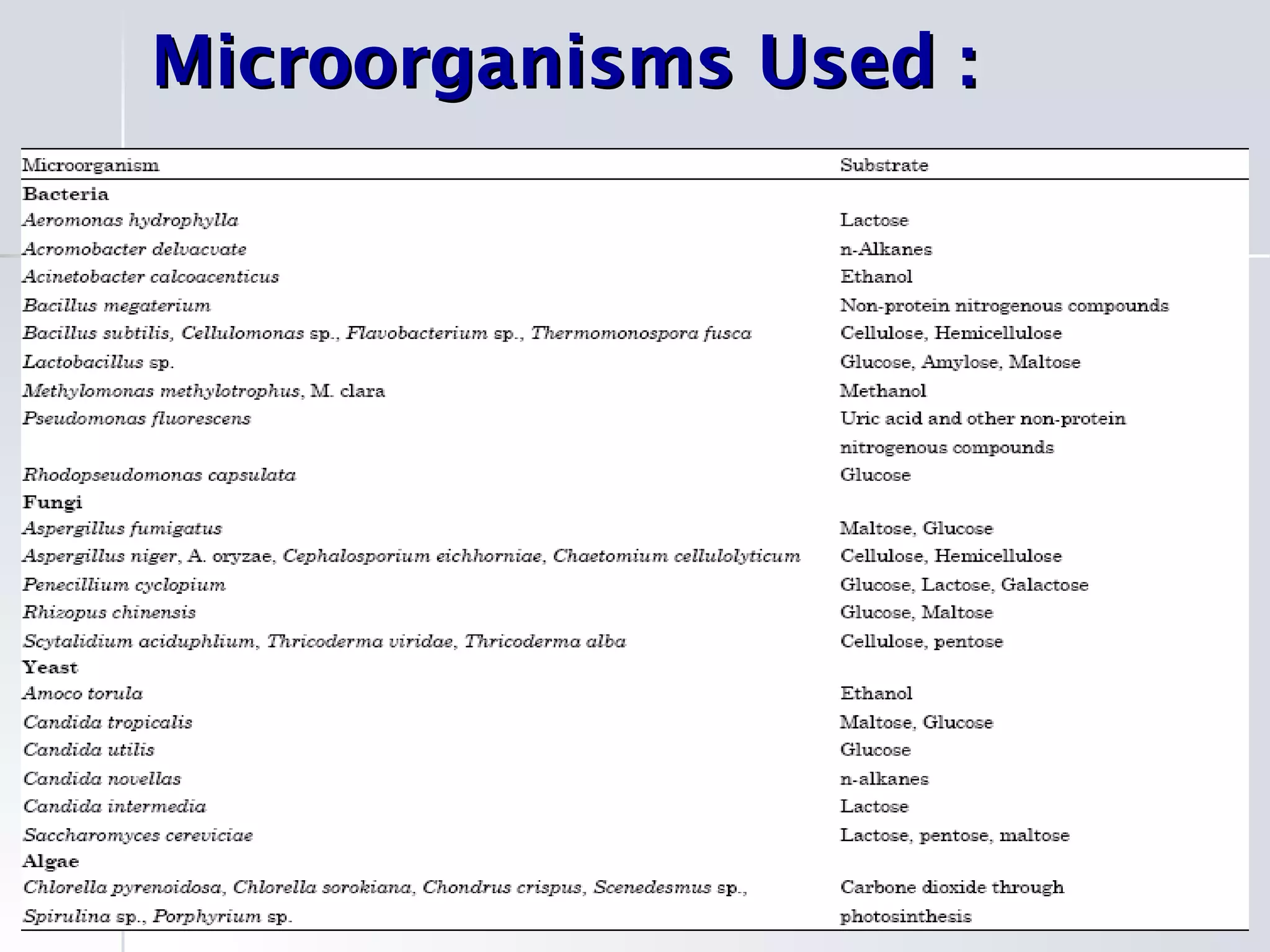

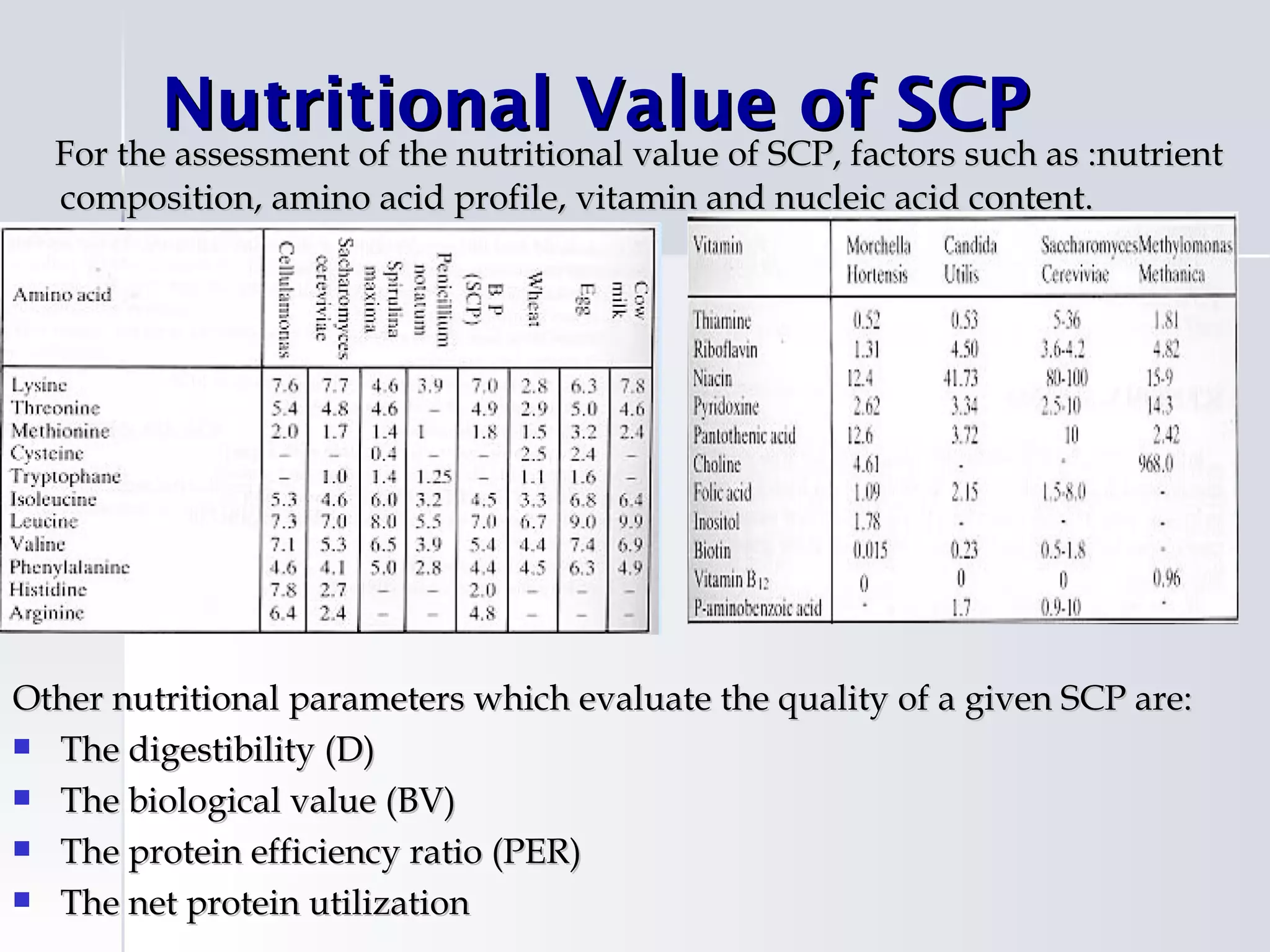

Single-cell protein (SCP), specifically yeast, algae, fungi and bacteria, is being investigated as a solution to the global food problem. SCP shows promise as an alternative protein source for both human and animal consumption. Key benefits include its high protein content, ease and speed of production, and ability to use waste materials as a substrate. However, SCP also faces challenges such as potentially high nucleic acid content and production costs that must be addressed. Continued research is needed to optimize SCP nutritional profiles and develop products that are cost-competitive and similar to familiar foods.