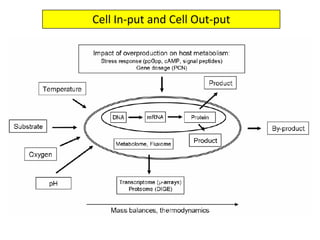

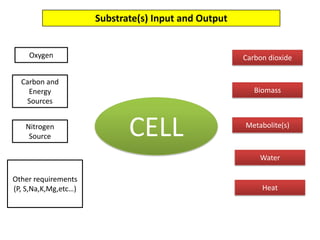

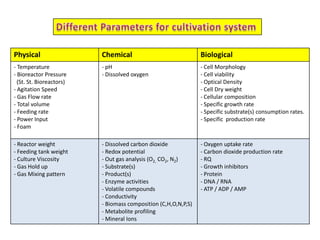

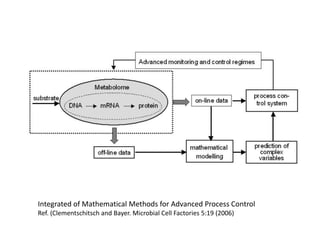

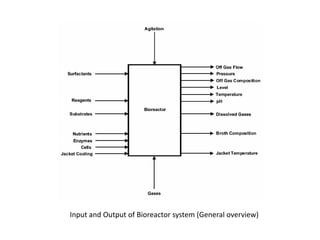

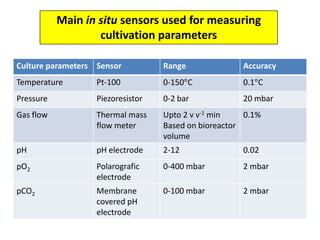

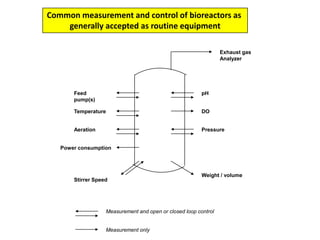

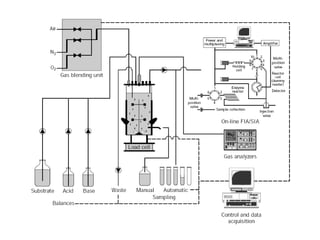

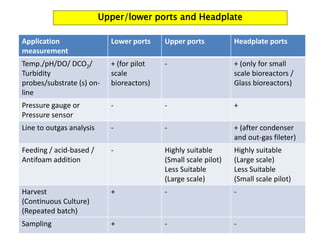

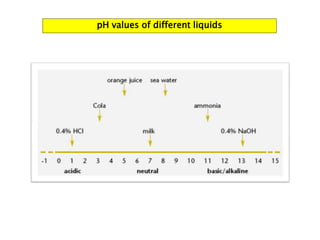

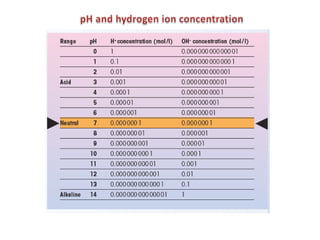

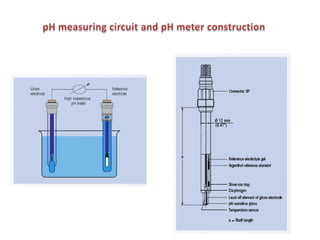

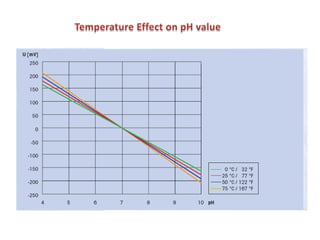

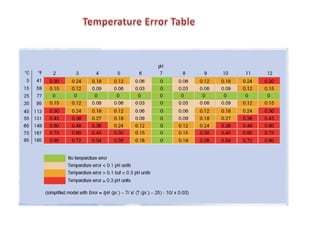

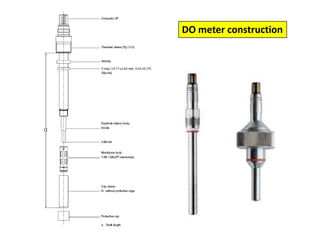

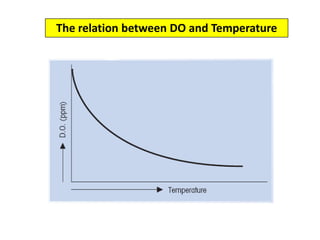

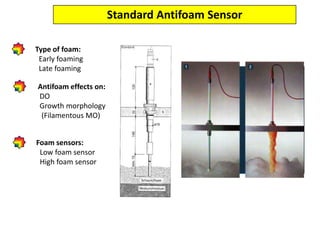

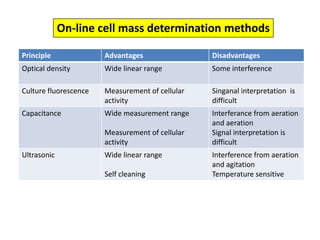

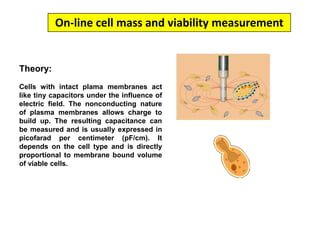

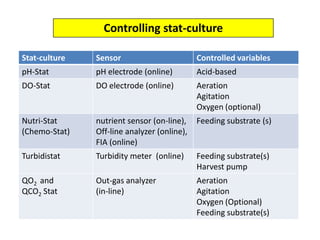

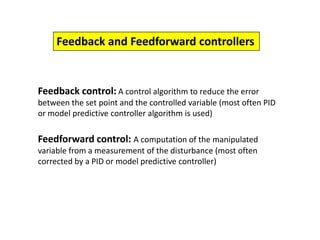

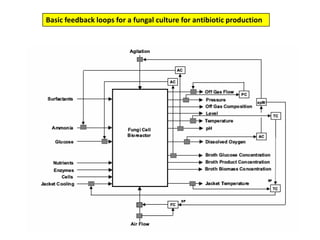

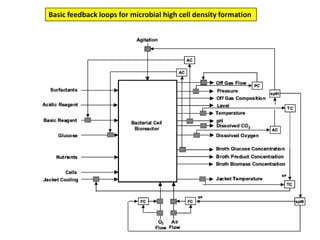

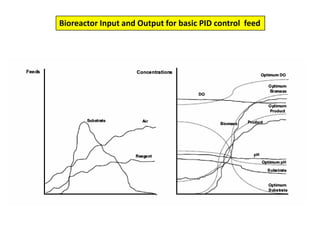

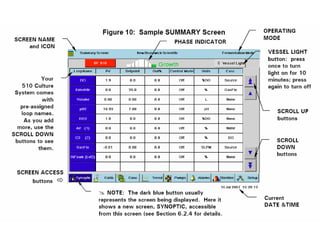

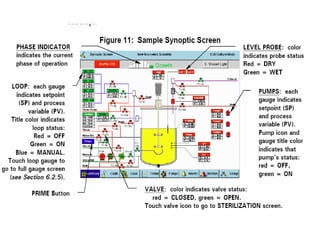

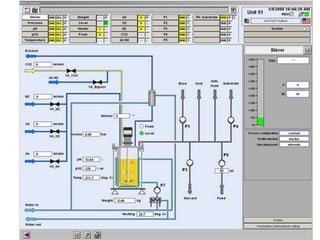

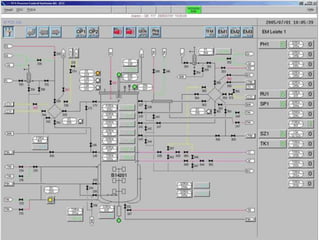

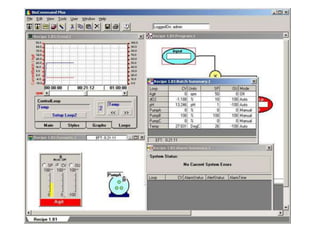

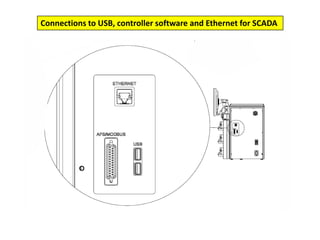

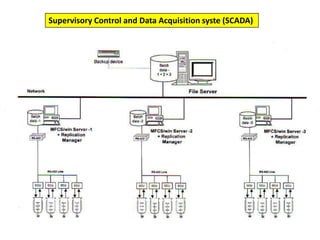

This document discusses bioprocess control for cell cultivation systems. It covers various parameters that are measured for control, including cell inputs and outputs, substrate levels, oxygen, carbon dioxide, temperature, pH, dissolved oxygen, and foam. Sensors used for online measurement of these parameters in bioreactors are also outlined. The document then describes basic feedback loops and controllers for bioprocess control, including PID and model predictive control. It concludes with an overview of using a supervisory control and data acquisition (SCADA) system connected over Ethernet for monitoring and controlling bioreactor systems.