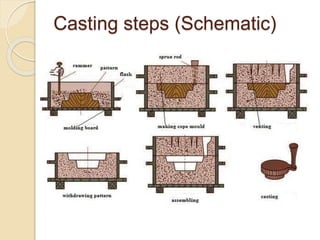

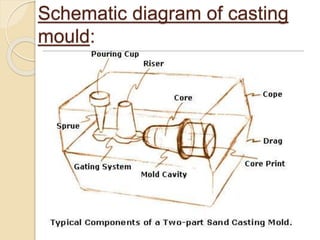

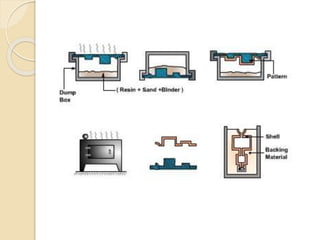

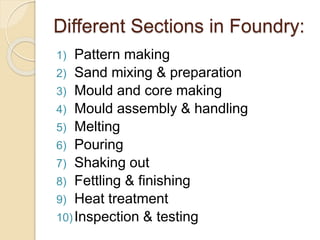

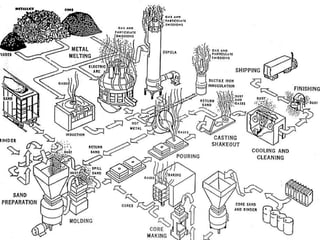

Metal casting involves pouring molten metal into a mold cavity to solidify into the desired shape, with common mold materials including sand. The main steps are making patterns and molds, melting metal, pouring into the mold, solidification, and finishing. Key casting methods include green sand molding, shell molding, and die casting which offer advantages like complexity of parts and better dimensional accuracy and surface finish compared to sand casting.