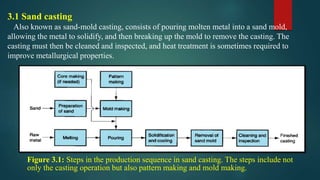

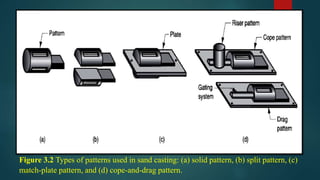

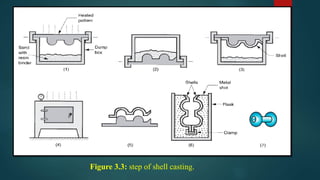

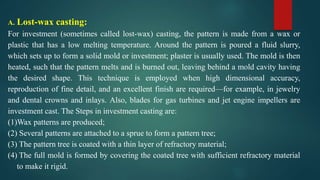

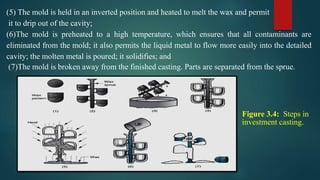

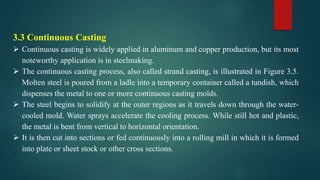

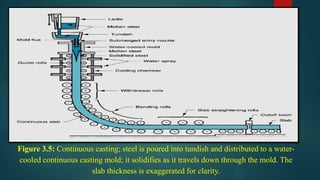

Sand casting involves pouring molten metal into a sand mold. Patterns are used to define the shape and are made of materials like wood, metal, or plastic. There are different types of patterns including solid, split, match-plate, and cope-and-drag patterns. Shell molding uses a thermosetting resin to bind sand into a thin shell mold with better dimensional accuracy than sand casting. Lost-wax casting involves making a wax pattern, coating it with refractory material to form a mold, then heating to melt out the wax leaving a cavity to pour molten metal into. Continuous casting is used for steel and involves pouring molten metal directly into a water cooled mold to slowly solidify into sheets or plates