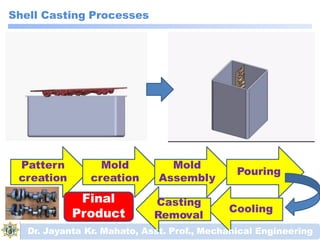

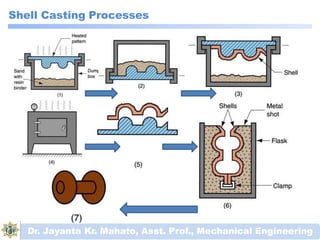

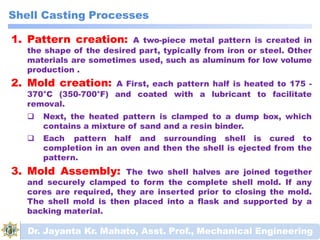

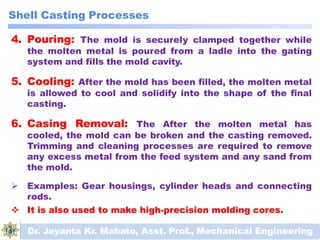

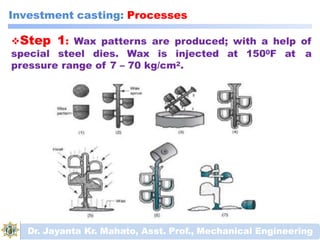

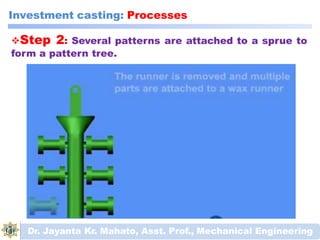

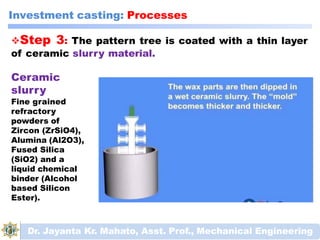

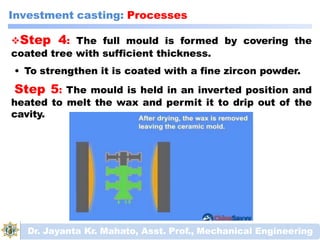

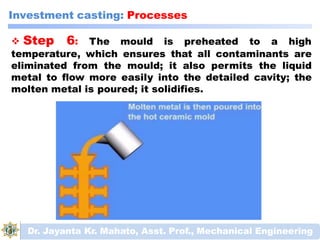

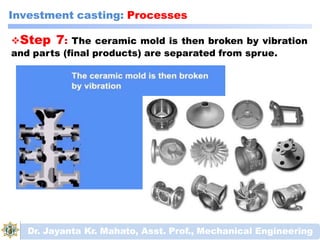

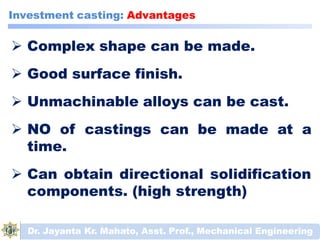

The document discusses shell casting and investment casting processes. Shell casting involves making a mold by applying a sand-resin mixture around a metal pattern. It is used to produce small to medium parts requiring high precision, such as gear housings and connecting rods. The investment casting process coats a wax pattern with ceramic slurry to form a mold, then melts out the wax to create a cavity for molten metal. It allows for complex, high-precision shapes and directional solidification of alloys. Both processes provide good surface finishes and high production rates compared to sand casting.