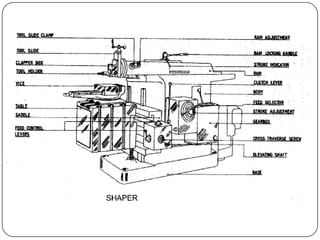

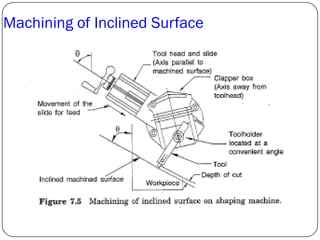

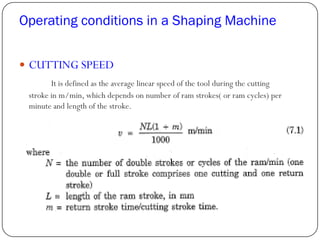

This document provides information about shaping, planning, and slotting operations. It discusses the differences between these processes and the machines used. Shaping and slotting involve reciprocating the tool while feeding the workpiece, while planning involves reciprocating the workpiece and feeding the tool. Examples of shaping machines include horizontal and vertical shapers. Key parameters that affect machining include cutting speed, feed, depth of cut, and material removal rate. Example calculations are provided to determine machining time and cost for specific shaping operations.