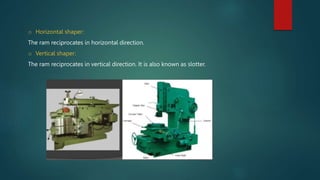

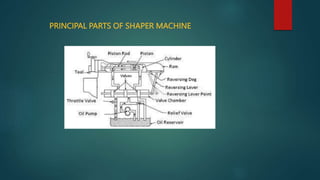

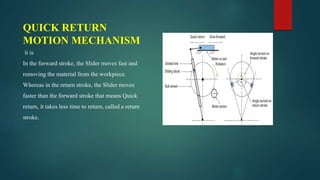

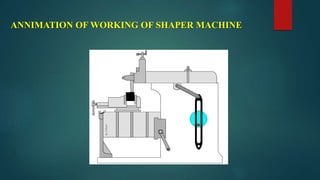

The shaper machine is used to produce flat or angled surfaces on a workpiece by reciprocating a tool in a straight line motion over the stationary workpiece. It has a ram that holds the cutting tool and reciprocates horizontally or vertically driven by various mechanisms like crank, gears or hydraulics. The table holds the workpiece and can move in cross-feed motions. As the ram moves forward in the cutting stroke, material is removed from the workpiece, and in the quick return idle stroke, the ram rapidly returns without cutting to prepare for the next cut. Shapers are classified based on the drive mechanism, ram position and table design, and are used to machine surfaces, slots, gears and other linear features