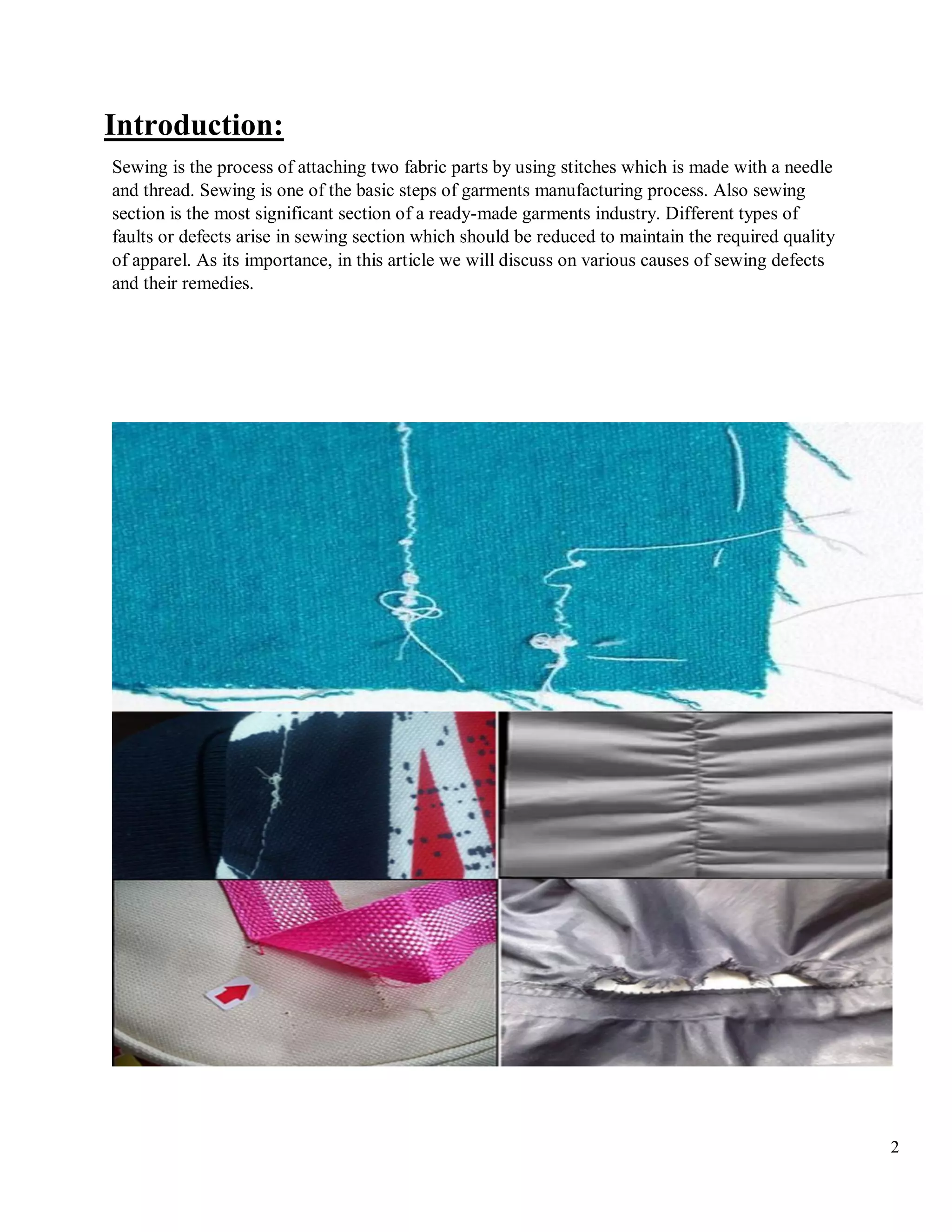

1. The document discusses common sewing defects that occur during garment manufacturing such as skipped stitches, seam slippage, needle thread breakage, and their potential causes.

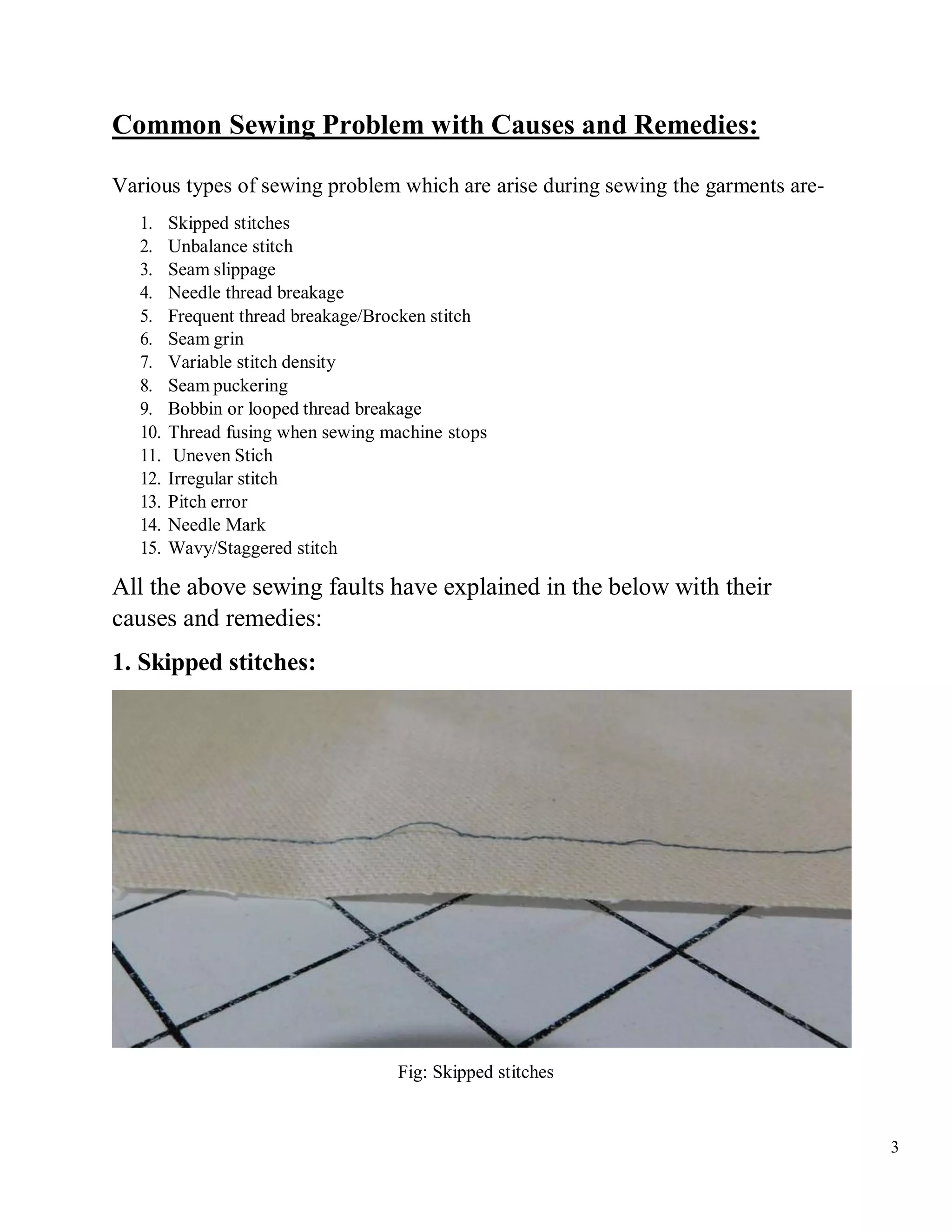

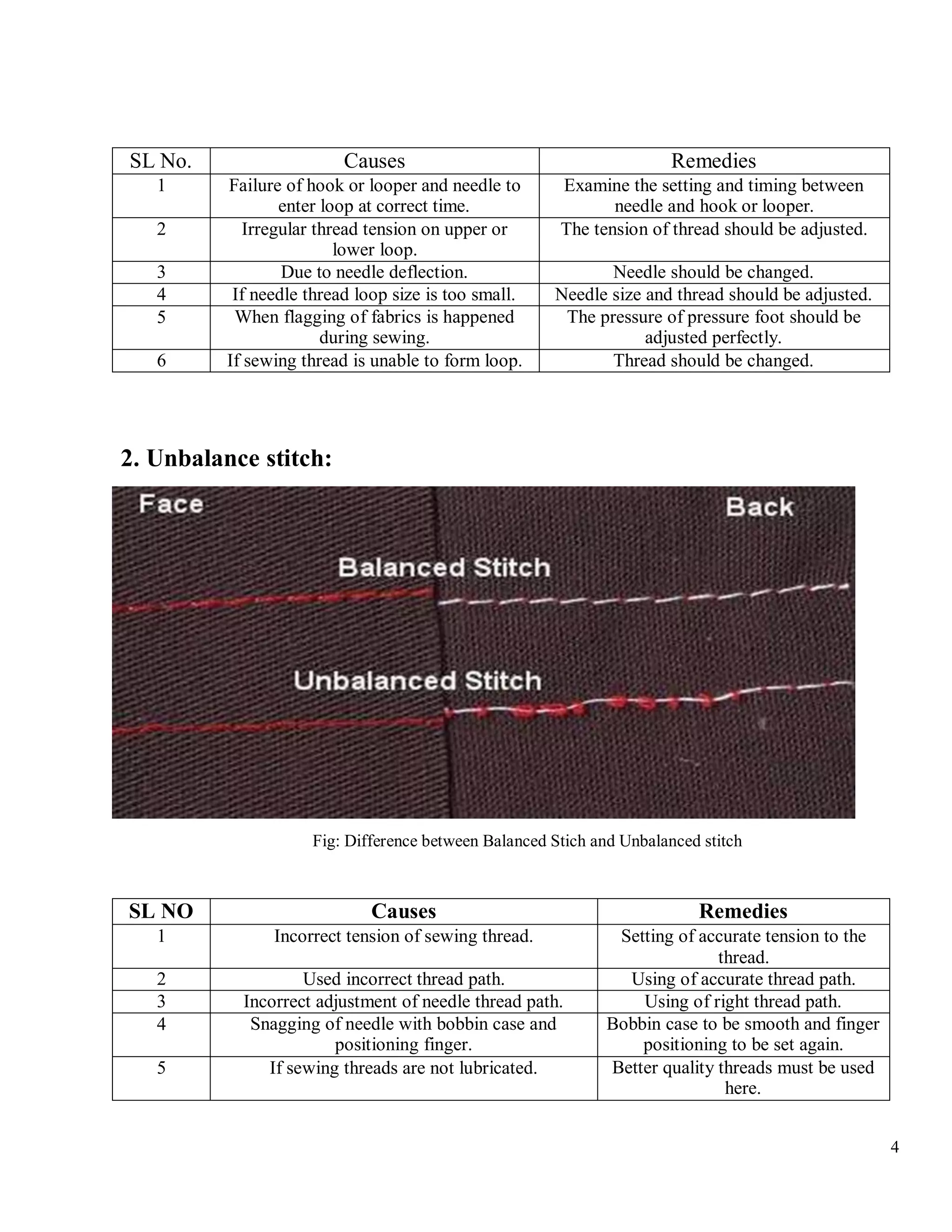

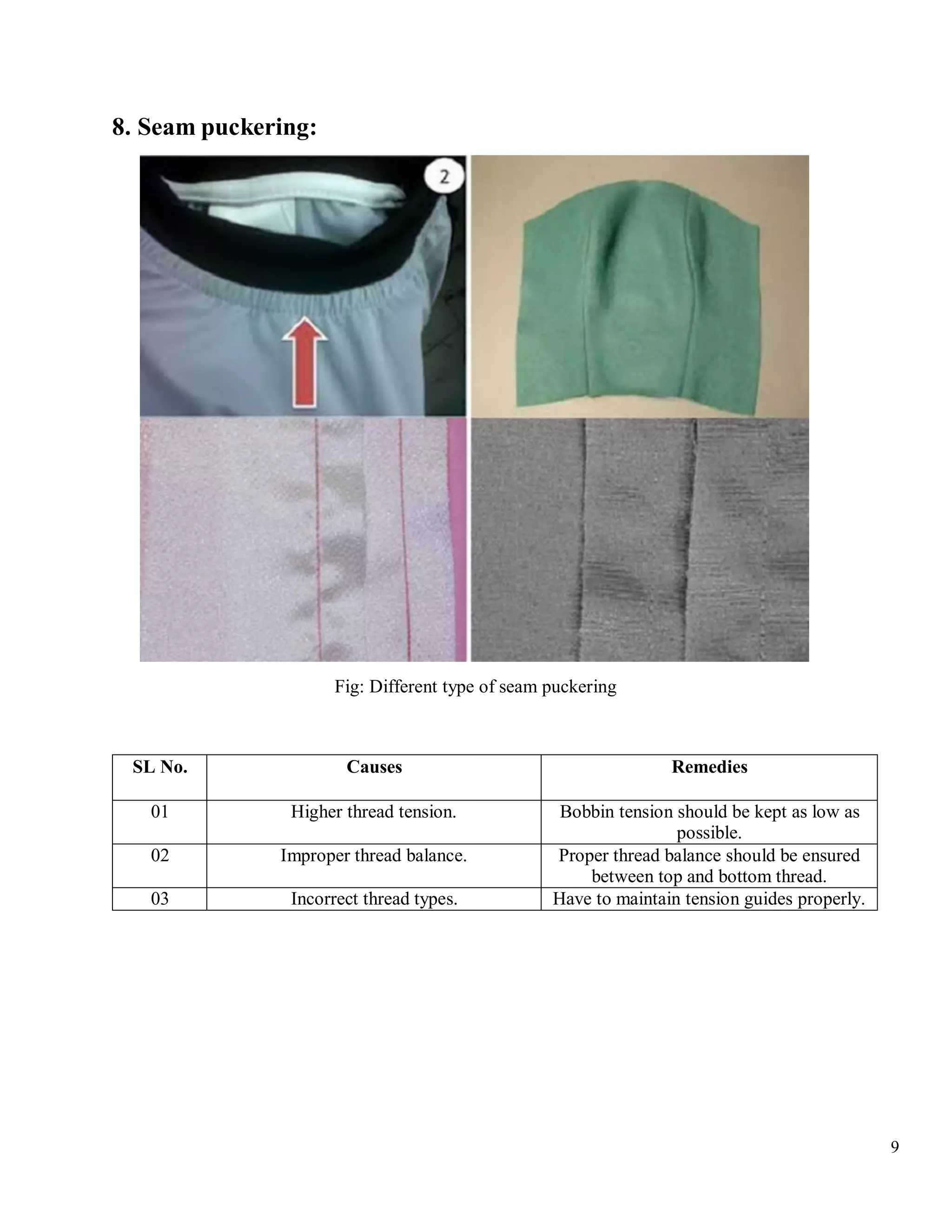

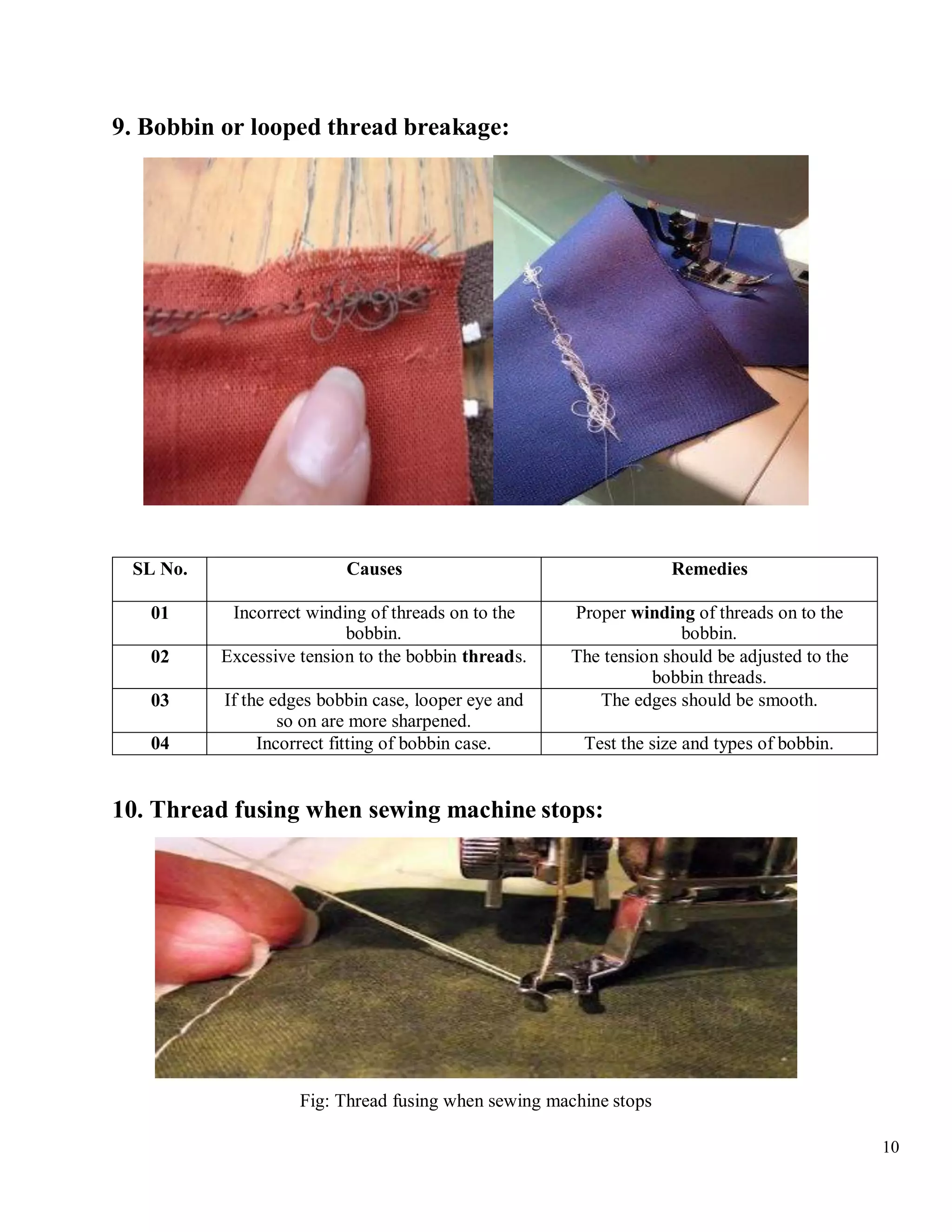

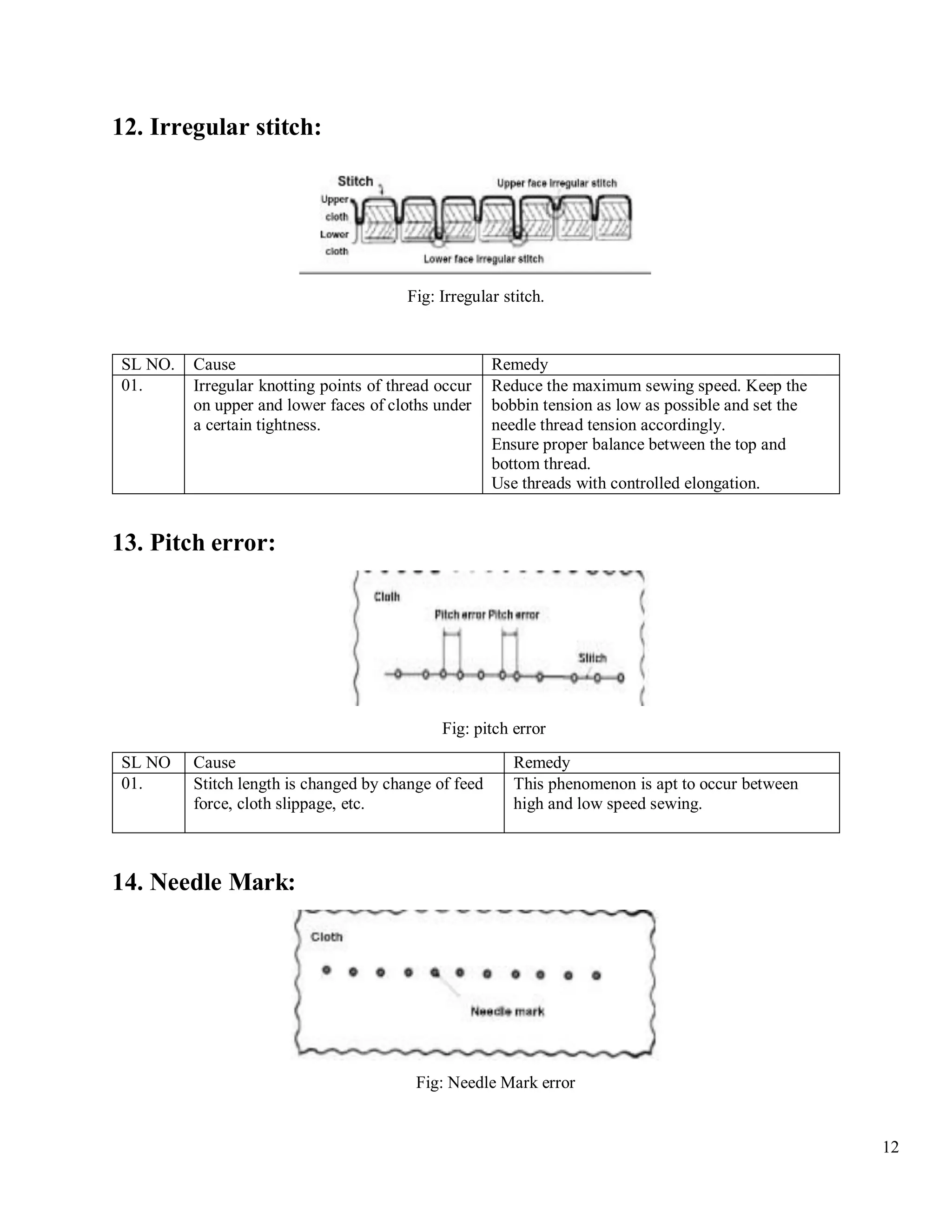

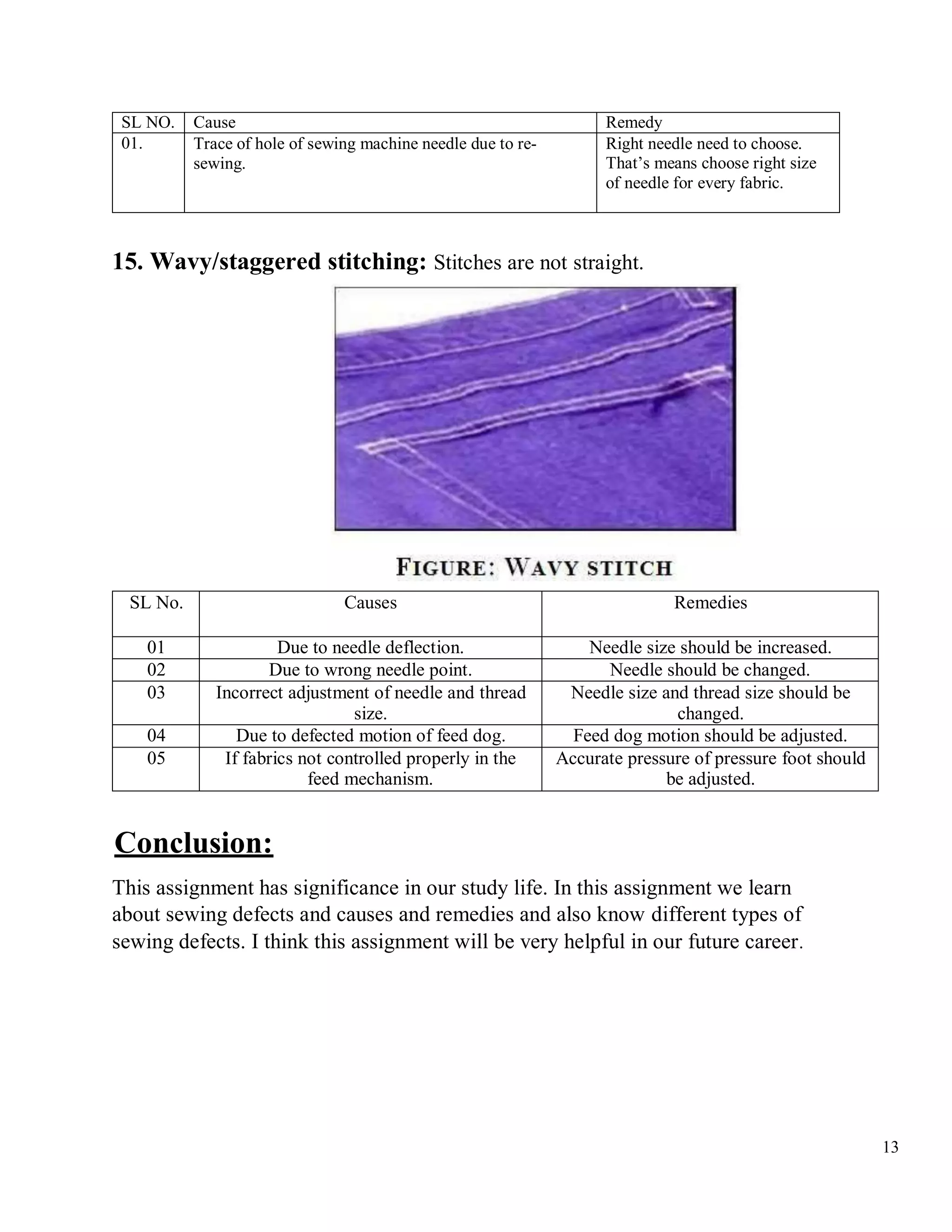

2. Fifteen common sewing defects are described along with their causes, which include issues with thread tension, needle size, thread quality, and machine settings.

3. For each defect, recommended remedies are provided such as adjusting thread tension, changing the needle, improving thread guidance, and optimizing sewing machine settings. Implementing these remedies can help reduce sewing defects and improve garment quality.