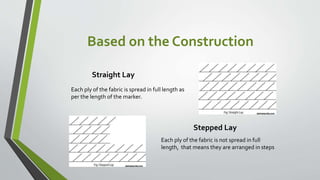

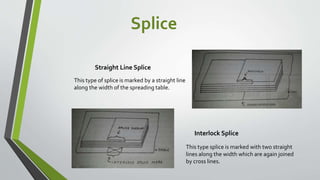

Fabric spreading is a process that lays out fabric plies to the required length and width for cutting. There are two main types of spreading: flat, where all plies are the same length, and stepped, where plies are arranged in steps of decreasing length. Fabric can be spread manually using hands or hooks, or mechanically using semi-automatic or fully automatic machines. The process must ensure plies are flat, tensioned correctly, and flaws are removed to prepare fabric for accurate cutting in bulk. Splices are used to join fabric when faults are found, and come in straight line or interlocked styles.