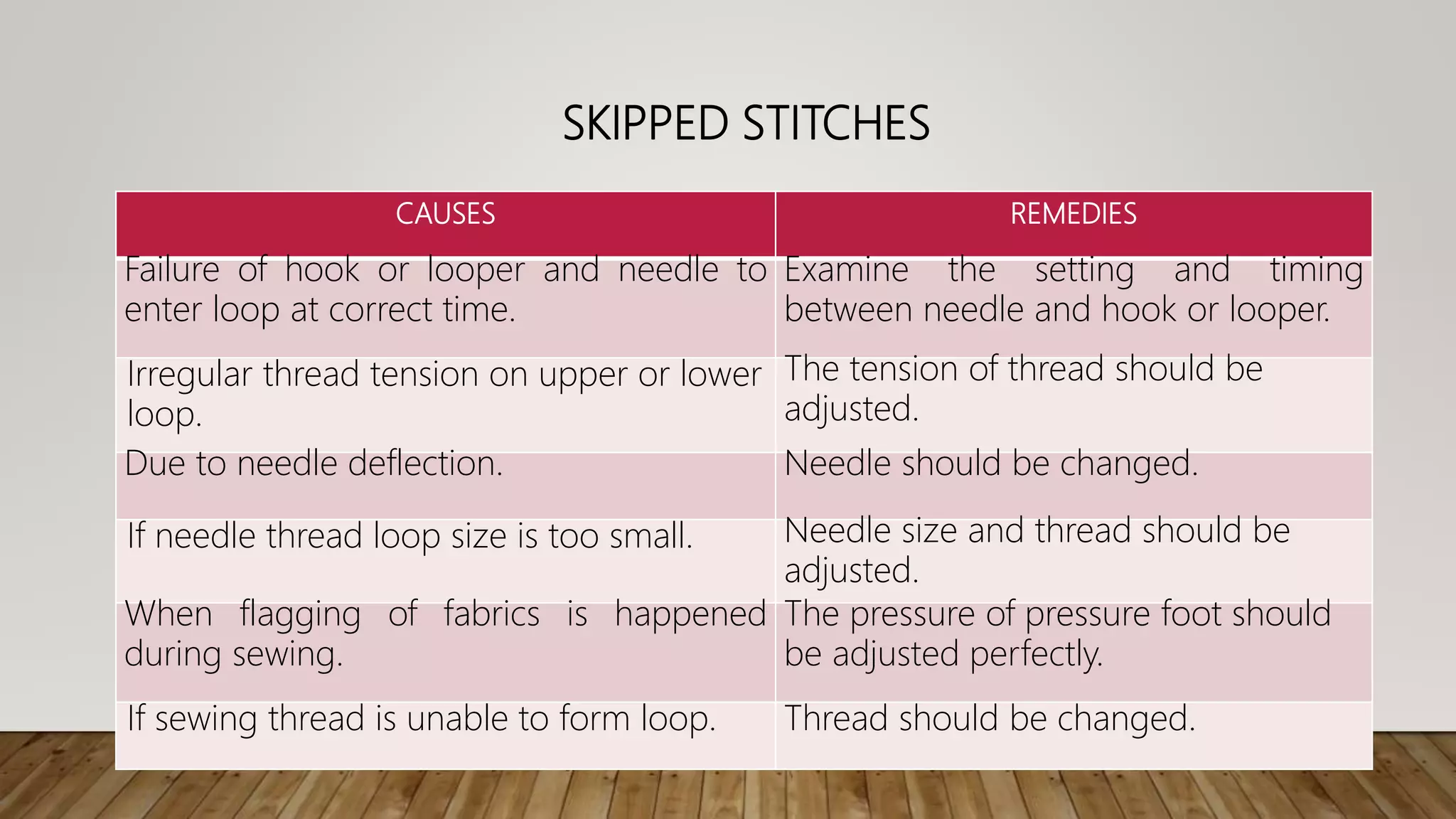

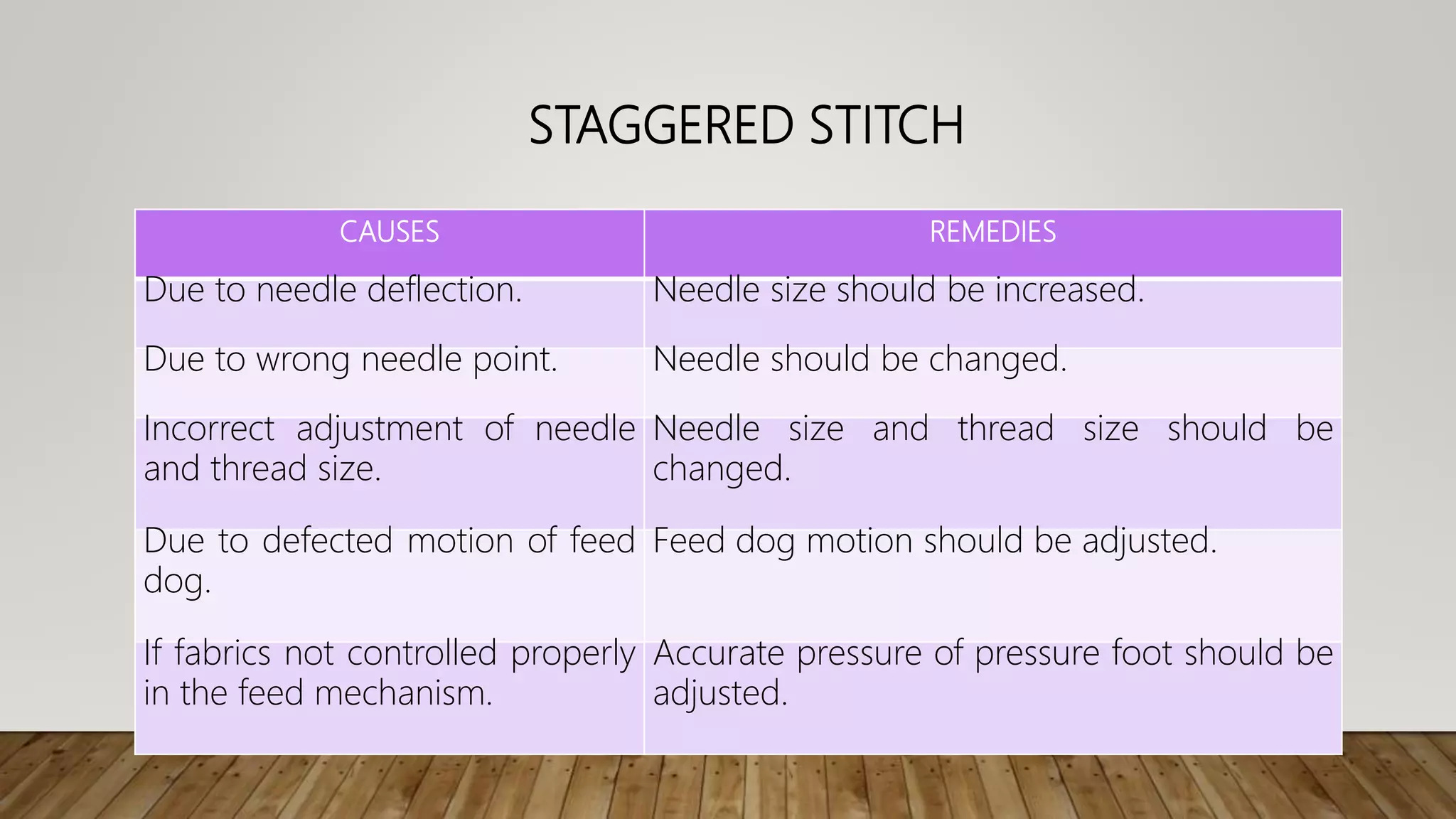

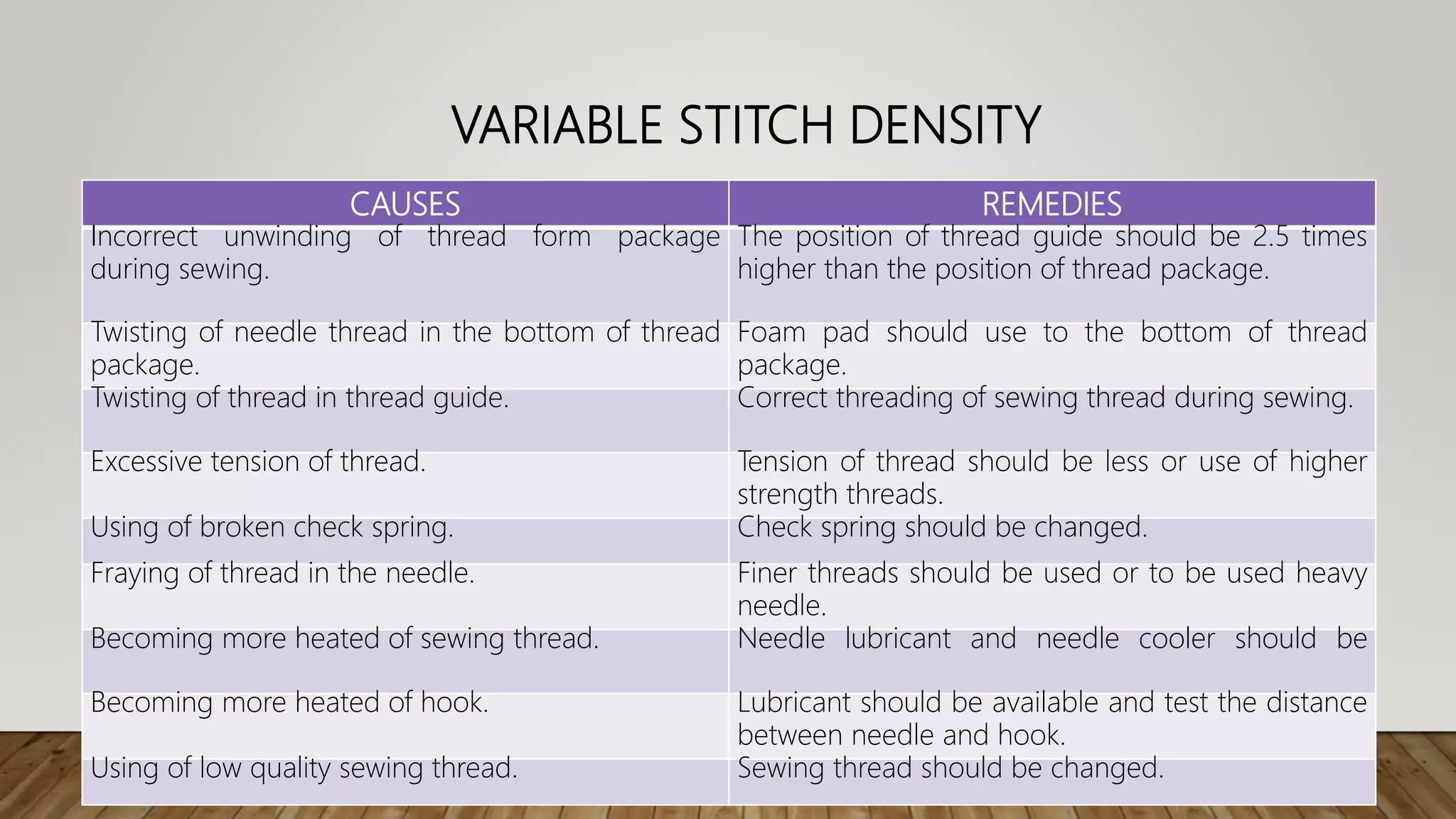

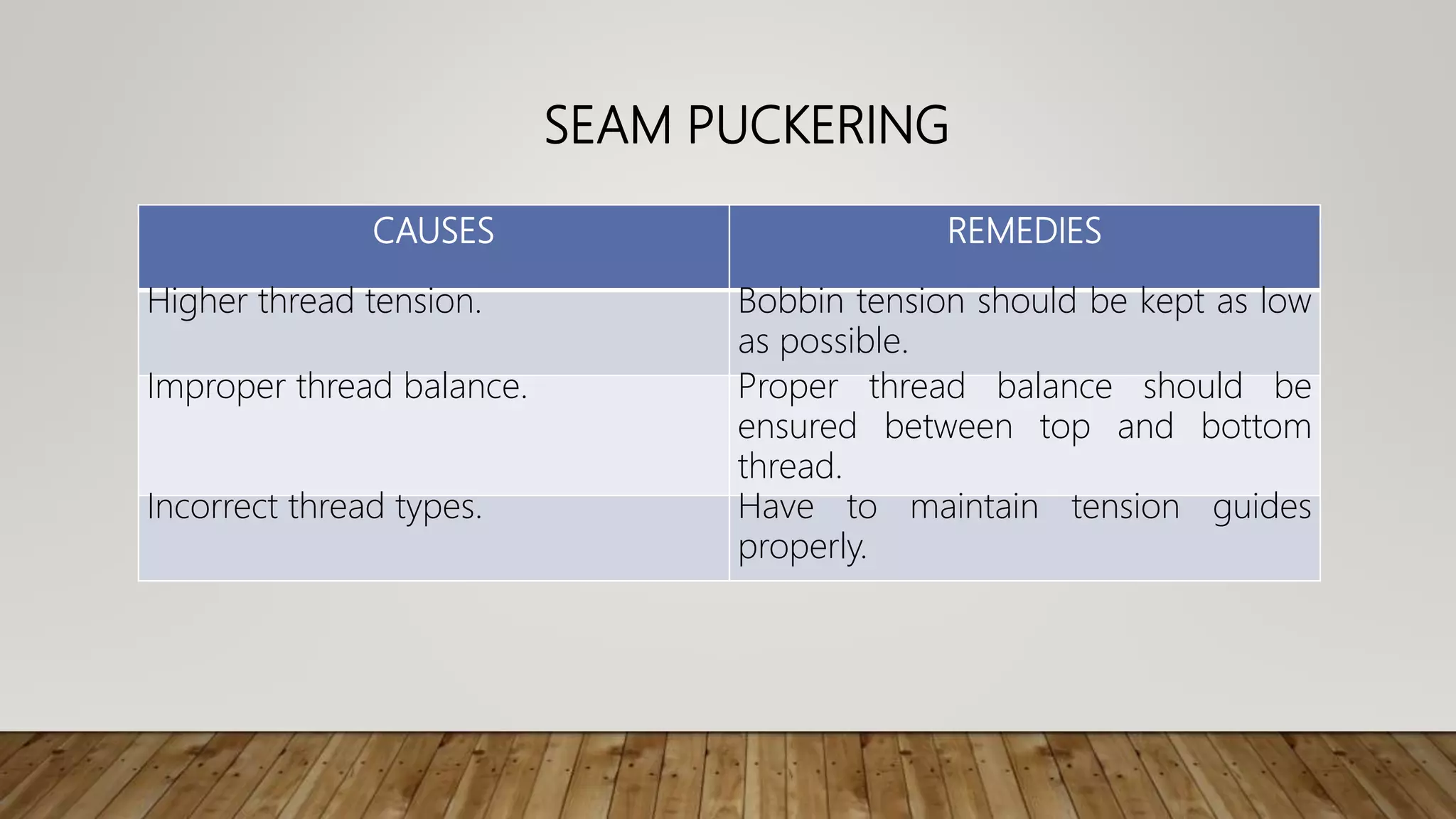

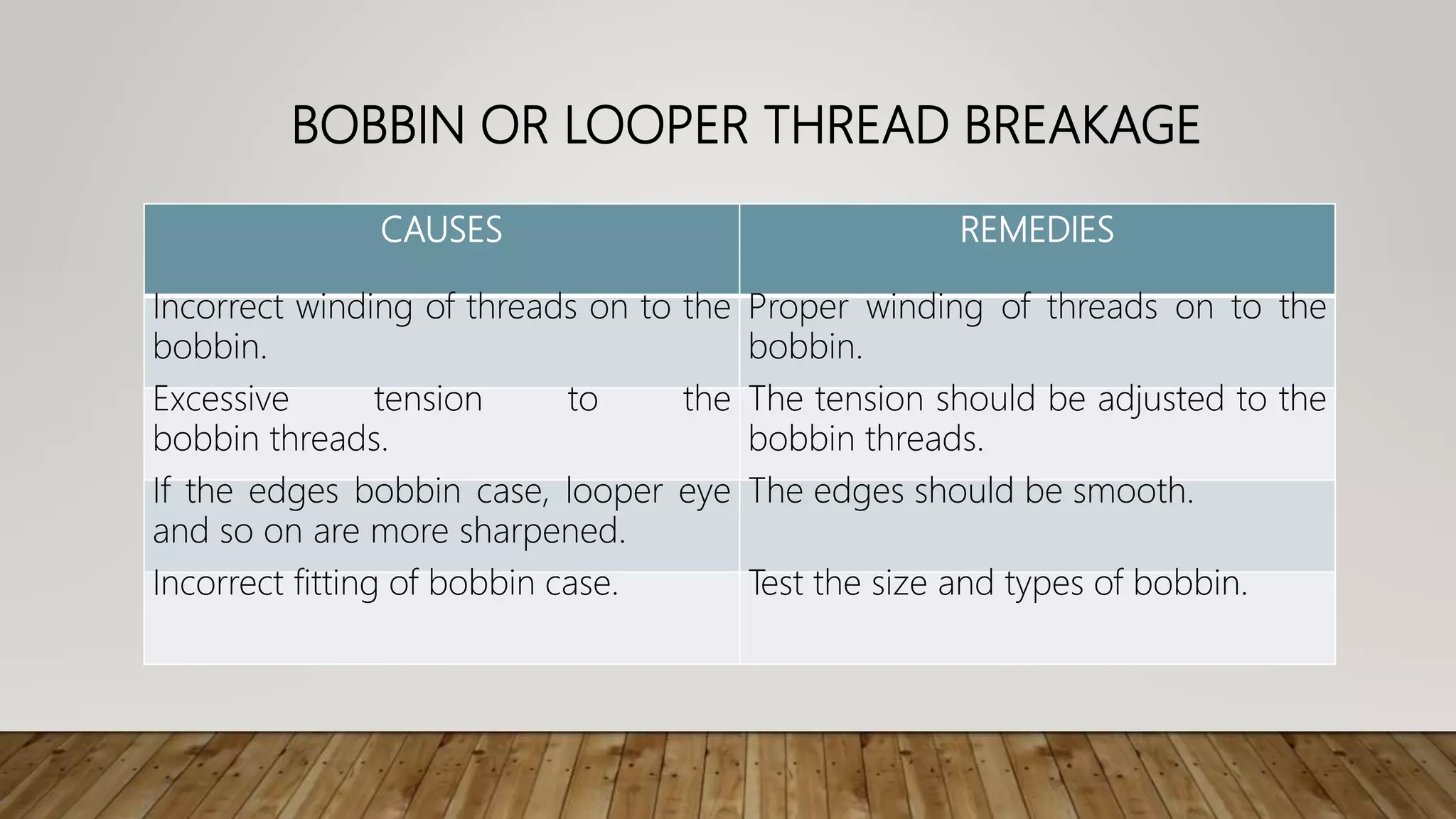

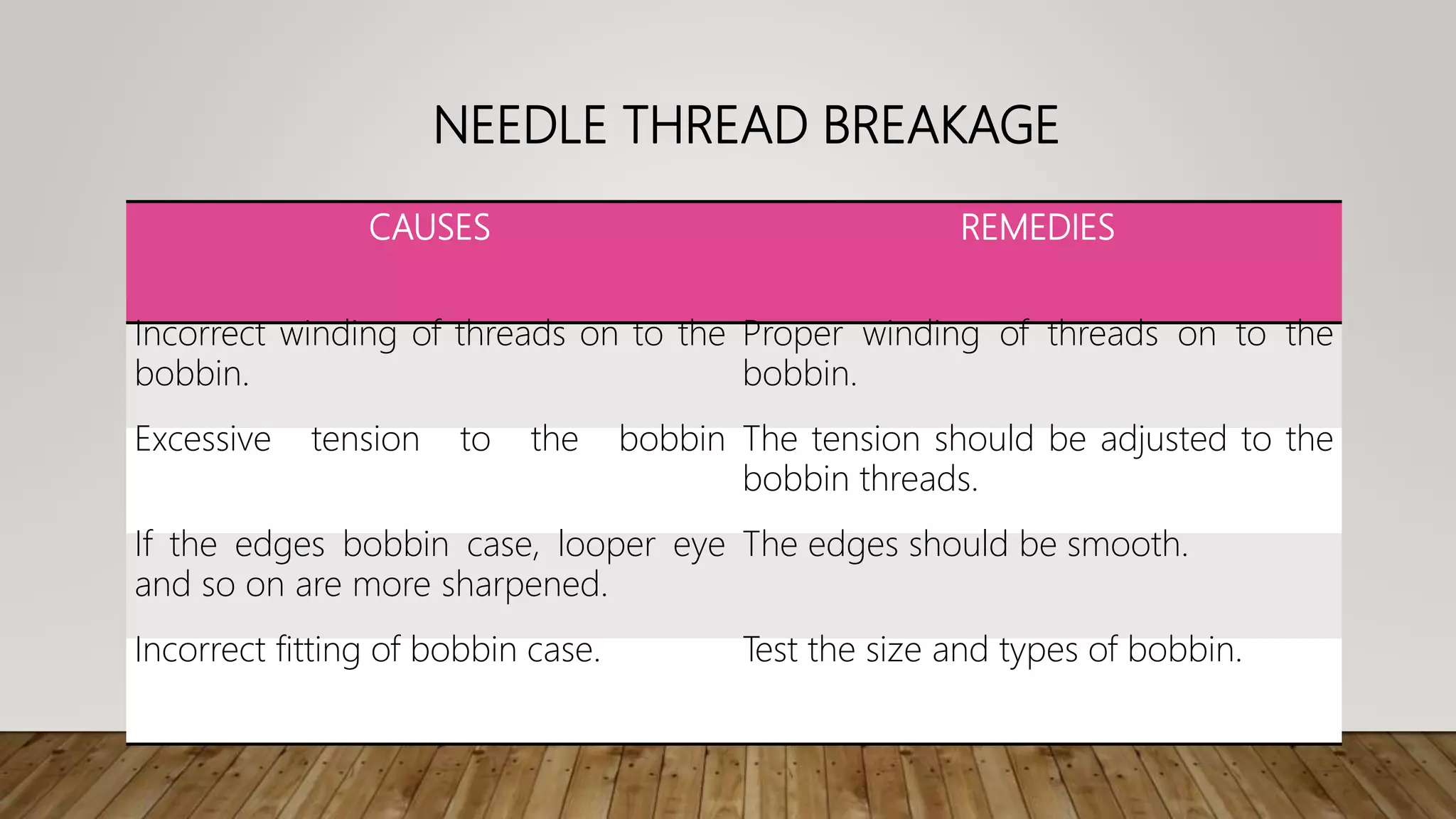

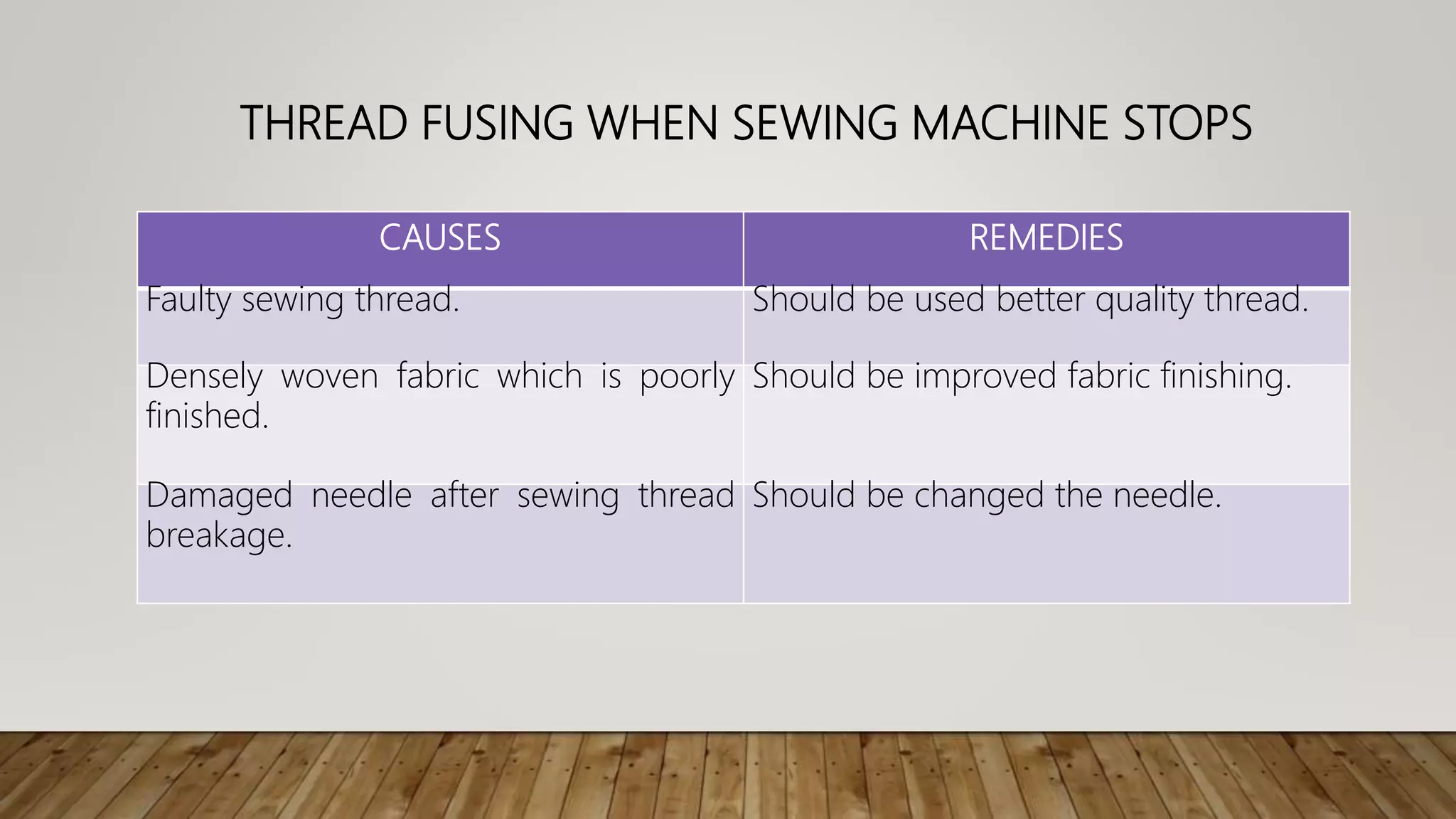

This document lists common sewing machine problems, their causes, and remedies. It discusses issues like skipped stitches, unbalanced stitches, staggered stitches, and variable stitch density. The causes outlined include things like thread tension problems, incorrect needle or thread sizes, fabric flagging, and damage to machine parts. The recommended remedies involve adjusting tensions, replacing worn parts, using the proper thread sizes and types, and addressing issues with the fabric.