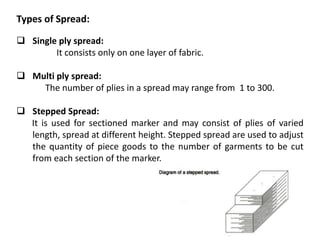

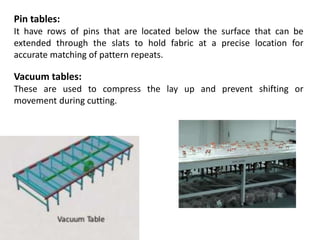

The document discusses various aspects of fabric spreading including types of spreads, spreading methods, quality considerations, and equipment used. It describes manual spreading using two people versus semi-automatic spreading carriages. Automatic spreaders can load fabric rolls, control tension, and cut fabric ends automatically. Quality depends on defects, tension, flatness, ply alignment, and static electricity. Setup involves preparing orders, tables, and machines. Spreading surfaces include pin tables, vacuum tables, and air flotation tables. Control devices manage tension while positioning devices monitor alignment. End treatment devices catch or cut fabric at the ends.