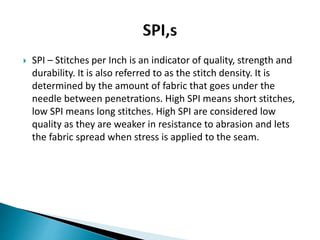

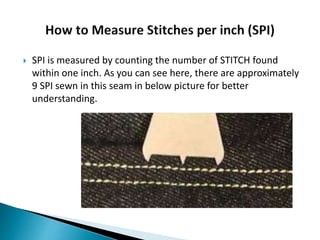

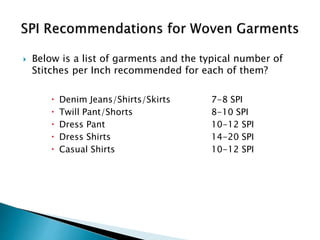

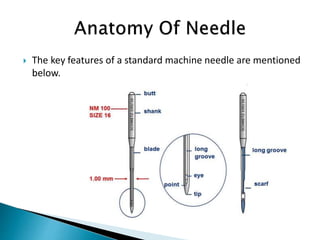

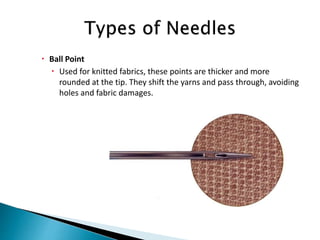

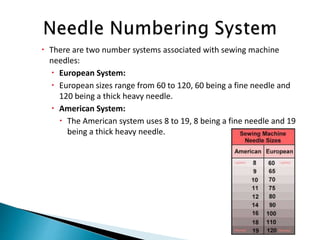

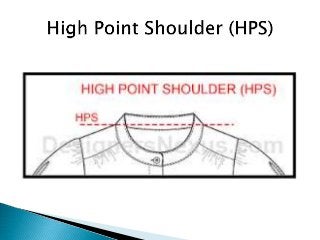

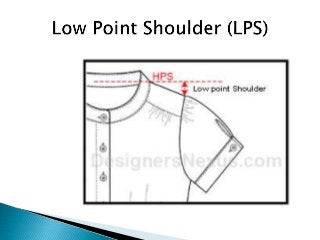

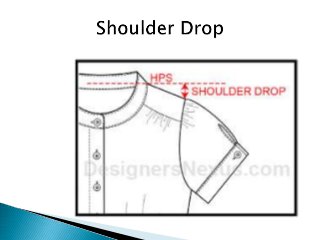

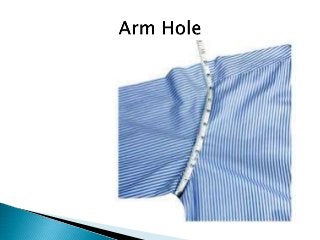

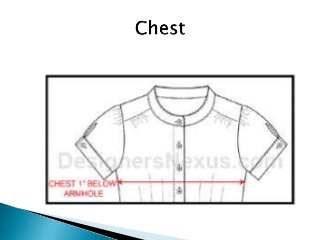

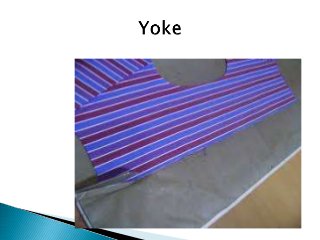

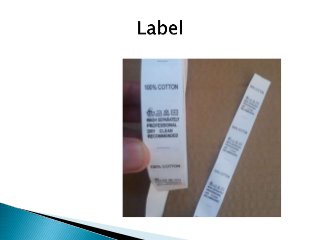

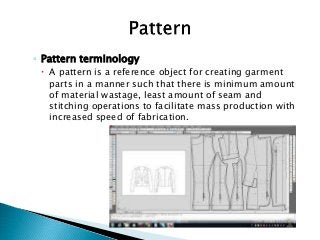

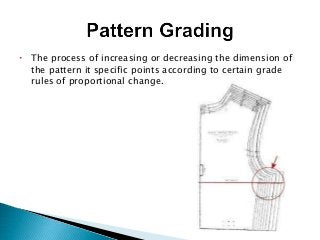

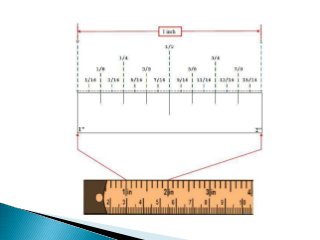

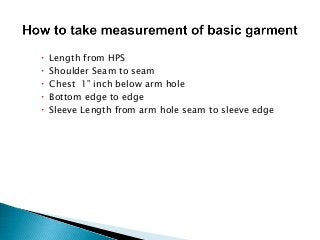

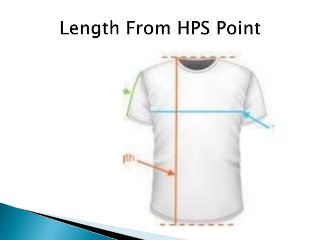

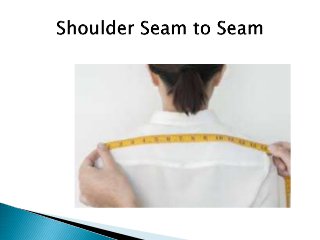

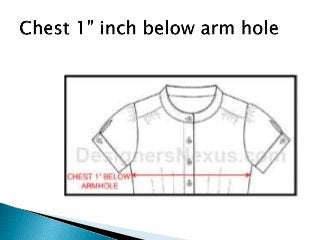

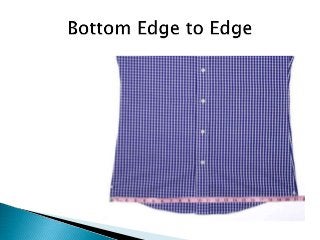

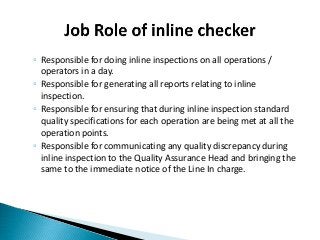

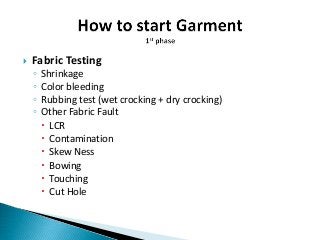

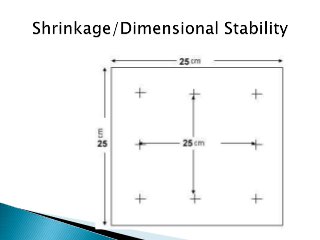

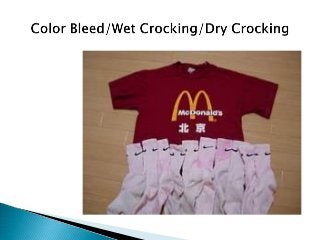

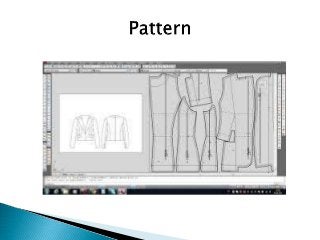

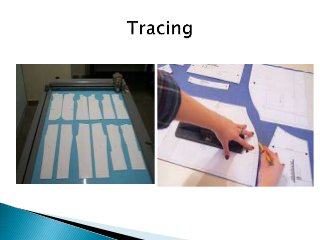

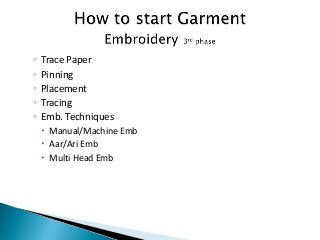

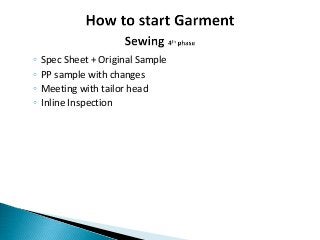

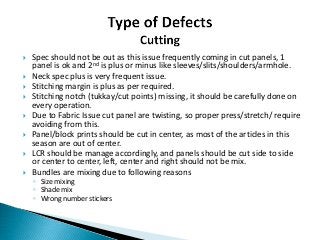

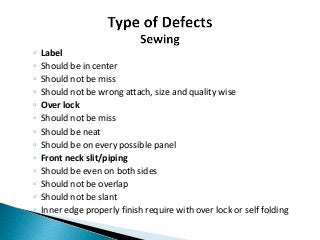

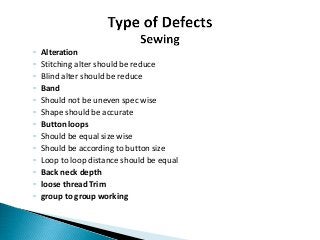

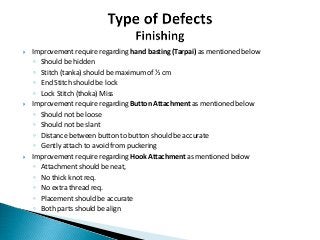

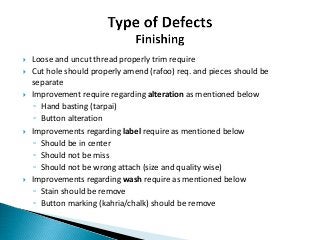

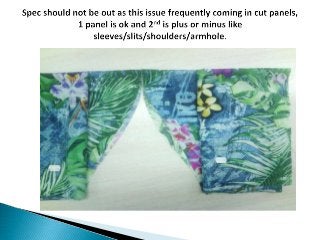

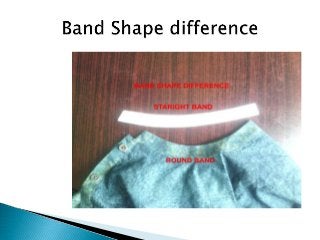

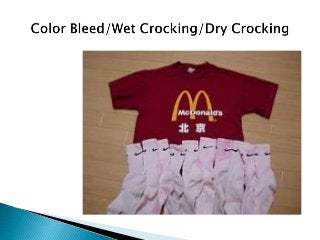

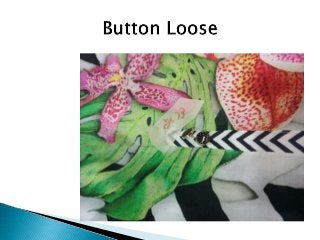

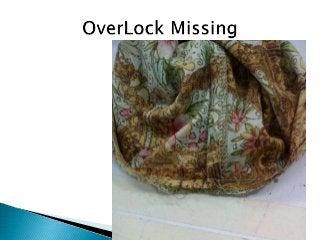

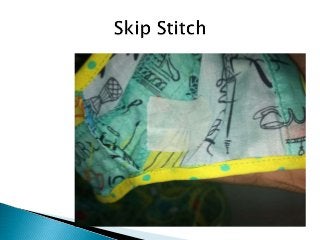

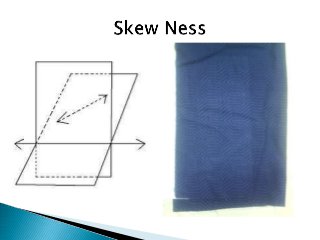

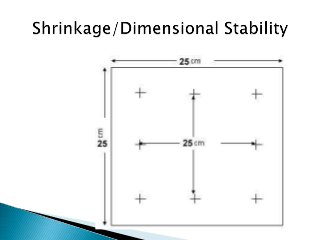

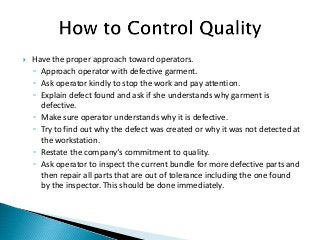

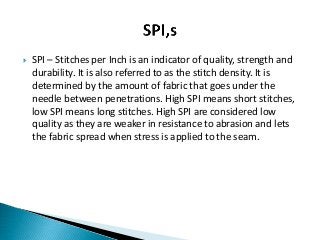

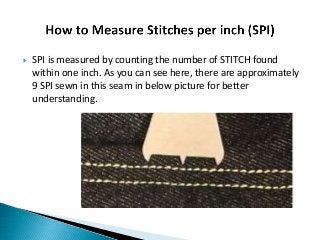

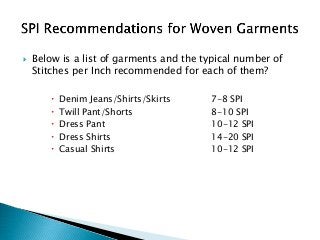

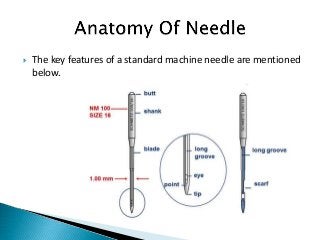

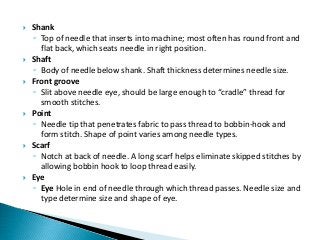

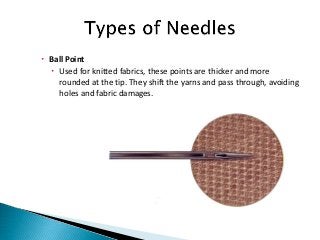

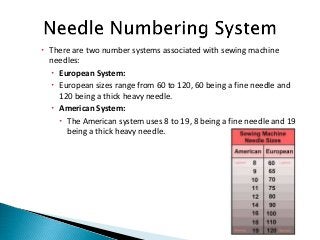

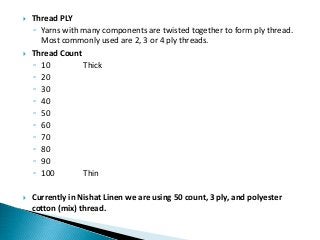

This document outlines the essential aspects of garment production, emphasizing the importance of quality and proper techniques in manufacturing for customer satisfaction. It covers various types of garments, construction terminology, and specifications in measurements and quality checks including inspections and fabric testing. Additionally, it highlights the roles of operators in maintaining quality standards and the significance of using the right tools and materials, such as sewing needles and threads.