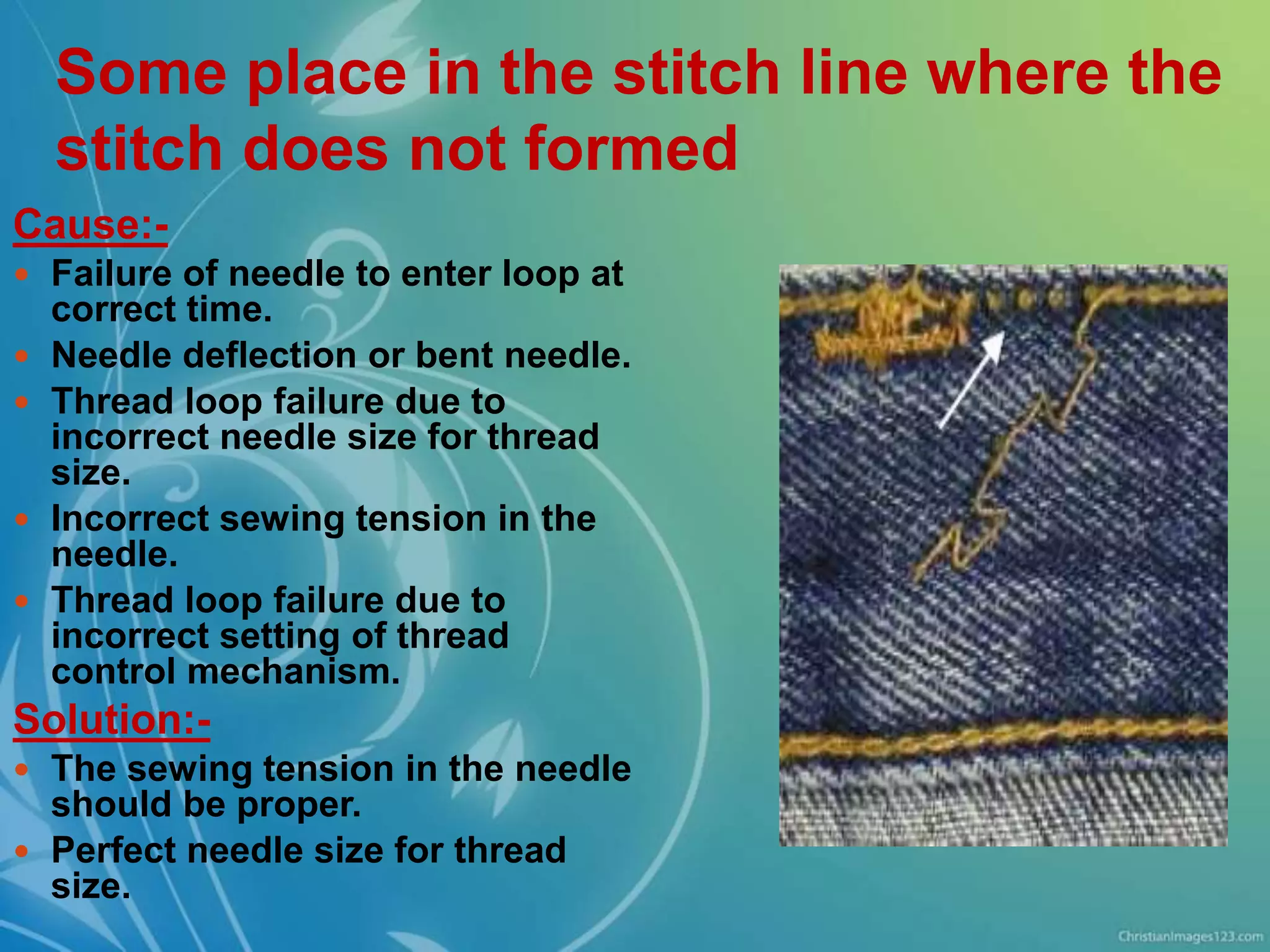

This document discusses quality control in garment sewing. It outlines several key factors in ensuring quality like proper fabric and materials, well-maintained machines, accurate stitching and measurements. Common defects like skipped stitches, shade issues, and seam puckering are described along with their causes and solutions. Maintaining quality is important to satisfy customers' expectations for the right product, quality, timeliness and undamaged condition. Close monitoring of all production steps from input materials to packaging is needed to control quality in garment sewing.