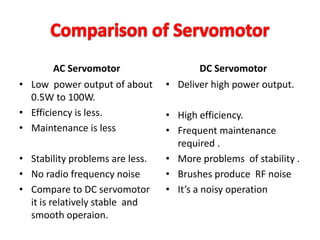

A servo motor is a rotary or linear actuator that allows for precise control of angular or linear position, velocity, and acceleration by responding to an external control signal. There are two main types: DC servo motors, which provide very accurate and fast response due to low inductive reactance but require more maintenance, and AC servo motors, which have lower power output but are more stable and have less maintenance requirements. Servo motors are used in applications that require precise control such as robotics, conveyor belts, cameras, automatic doors, and solar tracking systems.