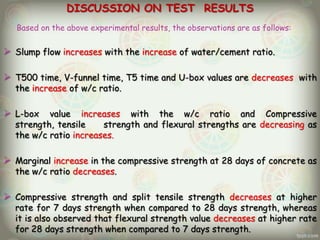

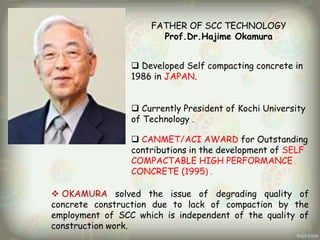

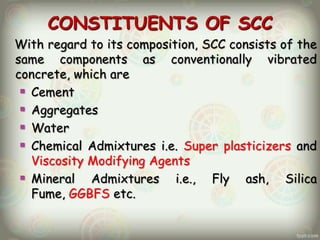

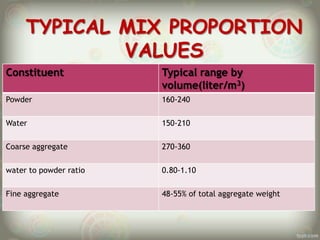

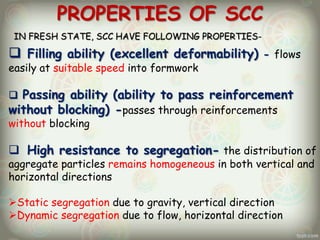

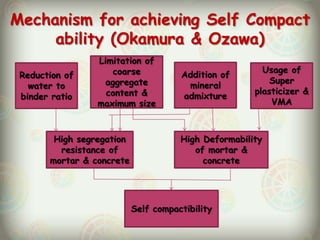

Self-compacting concrete (SCC) was developed in Japan in the 1980s to solve issues with inadequate concrete compaction. SCC is highly flowable under its own weight and fills formwork without vibration. It was pioneered by Professor Hajime Okamura and has seen increasing use globally since 2000. The document discusses the constituents, properties, testing, and advantages of SCC compared to traditional vibrated concrete.

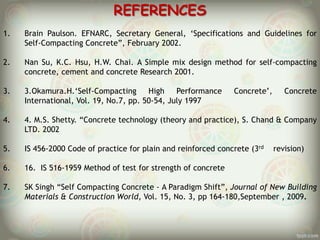

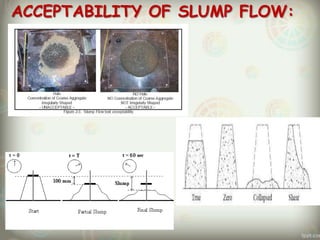

![ACCEPTANCE CRITERIA FOR SCC IN FREE STATE

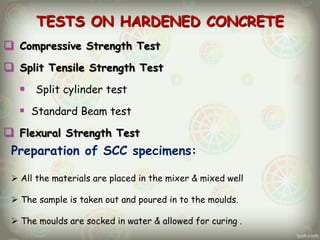

Test Results on Fresh Concrete and Acceptance Criteria for SCC

S. No

Method

1

Slump

Flow

Test

Unit

Water/Cement Ratio

0.23

0.24

0.25

0.26

EFNARC[3]

0.27

Specification

Remarks

SF1: 550-650

mm

655

660

665

680

700

SF2: 660-750

SF2

SF3: 760-850

VS1: T500 ≤ 2

2

T500

sec

3.94

3.88

3.82

3.32

2.50

3

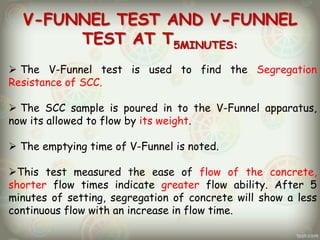

V-Funnel

sec

8.50

8.35

8.10

7.95

6.89

VF1: ≤ 8

4

T5min

sec

11.89

10.92

10.66

10.23

9.95

VF2: 9-25

5

L-Box

h2/h1

0.950

0.959

0.969

6

U-Box

mm

9

7

6

0.975 0.980

5

4

VS2: T500 > 2

PA1: > 0.8

(2 rebars)

PA2: > 0.8

(3 rebars)

0-30 [23]

VS2

VF2

PA2

OK](https://image.slidesharecdn.com/itsfinalppt-140227130236-phpapp01/85/self-compacting-concrete-21-320.jpg)